Finding the right OEM & ODM cycling apparel manufacturer in Australia can make or break your cycling brand. Launching a new bike clothing line? Outfitting your cycling club? Scaling an existing business? You need a manufacturer that delivers premium quality, flexible MOQs, and reliable production.

The challenge? Australia's cycling apparel manufacturing landscape is diverse. You'll find sustainability-focused local producers. You'll also see internationally-backed operations offering Italian fabrics and European craftsmanship.

I've spent weeks researching the top 10 OEM & ODM cycling apparel manufacturers in Australia . I compared minimum order quantities and pricing structures. I looked at fabric technologies and production timelines.

This guide breaks down each manufacturer's strengths and weaknesses. You get ideal customer profiles for each one. I've included a detailed comparison table too. Plus, you'll find expert insights on choosing the perfect partner for your specific business needs.

I'll also introduce you to an international alternative. Australian brands use it to achieve cost-efficiency without compromising quality.

Here are the manufacturers shaping Australia's cycling apparel industry.

SCODY - Australian-Made Sustainable Cycling Apparel Leader

SCODY has been making performance cycling gear in Brisbane since 1997. The current owners took over in 2004. They turned this maker into a green energy leader. The factory at 310 Montague Road, West End runs on solar power. Inside, dozens of sewing machines produce custom bike wear for Australia's top cyclists.

This small maker competes with big global brands. SCODY makes cycling jerseys , bib shorts , and track skinsuits that match premium quality. Their Elite Contour series meets—and often beats—world-class standards. Most Australian state cycling teams wear SCODY skinsuits for track races. You'll also see their gear at Commonwealth Games and Olympic events.

Manufacturing Model & Sustainability

SCODY uses a two-part production system. Main work happens in their Brisbane shop. Some steps finish in Fiji. This "made to order" method creates almost zero waste.

Their green efforts go beyond solar power:

Recycled polyester yarns in all polyester fabrics

Polyester waste gets turned into feedstock for reuse

Plastic removed from 99% of business operations

Custom Production Capabilities

SCODY creates all patterns and designs in-house. Product testing is thorough. For one skinsuit project, they tested six sleeve fabrics and eight body fabrics at once. Wind tunnel testing at cycling tracks fine-tunes air flow and seam spots.

Minimum order requirements : Details not shared online—you need to contact them for wholesale cycling clothing quotes.

Product range : Road cycling kits, track skinsuits, triathlon suits, running gear, corporate teamwear.

Best for : State teams, racing cycling clubs, brands wanting Australian-made green production, corporate clients looking for top-grade technical cycling garments .

SCODY doesn't sell through middle-men. They sell direct to retail customers and teams.

Ventou - Premium Custom Cycling Wear Specialist

Walk into Ventou's Brooklyn facility—just 20 minutes from Melbourne CBD. You'll see 25 years of custom cycling apparel expertise in action. This isn't a newcomer testing the waters. Ventou has spent over three decades perfecting cycling jerseys , bib knicks, and technical outerwear. Australia's most demanding riders trust their gear.

The numbers tell the story. Thousands of cycling clubs trust Ventou. Corporate teams count on them. Bike shops stock their gear. Third-party cycling apparel brands use their manufacturing. This Melbourne maker serves everyone. Weekend warriors to branded racing teams.

European Fabrics Meet Melbourne Manufacturing

Ventou sources fabrics from trusted European cycling apparel's suppliers only. No budget synthetics. No questionable materials. They use the same textiles you'll find in premium Italian brands. But they produce everything in Brooklyn.

Their design team handles two paths. Got your own artwork? Ventou manufactures it to match your vision. Need complete design support? Their designers create custom graphics from scratch.

The product range covers every cycling need. Merino jerseys for winter. Lightweight summer kits. Thermal arm warmers. Cycling gloves . Neck warmers. Vests. Jackets. They also produce triathlon suits , running gear, and MTB clothing under one roof.

Fast Turnaround, Personal Service

Ventou manages every order from start to finish. One point of contact. Clear communication. Fast, reliable shipping.

Minimum orders : Contact them for wholesale cycling clothing quotes.

Product range : Complete cycling kit collections. Corporate teamwear. Private label cycling apparel manufacturing.

Best for : Cycling clubs that need consistent quality. Bike shops building house brands. Corporate teams that want European fabrics with Australian production speed. Brands that need reliable custom bike wear factory partnerships.

Ventou launched the Brooklyn Project label in 2016. Premium quality without premium pricing. That philosophy drives their entire OEM/ODM operation.

Black Sheep Cycling - Flexible MOQ with China Production

Black Sheep Cycling breaks the mold. Cyclists founded this Australian brand because they knew the pain of high minimum orders. They built their name on being accessible. Design happens in Australia. Production happens in China. This setup fixes a huge problem for new cycling brands and small clubs.

Most manufacturers want 50-100 units per design. New brands testing the market can't afford that. Black Sheep Cycling changes the game. Their minimum order quantity starts at just 10 pieces per style . You can start a cycling brand with $2,000-3,000 instead of $15,000-20,000.

The Australia-China Production Advantage

The design team works from Australia. They know what local riders need. Hot summers. Changing weather. Tough demands for racing. They refine every pattern using Australian rider feedback. Then production begins.

China-based manufacturing keeps prices low. Black Sheep runs tight quality checks. They use top-grade fabrics—the same stuff European performance cycling clothing brands use. YKK zippers. Italian chamois pads. Sublimation printing that stays bright after 50 washes.

Product range : Cycling jerseys , bib shorts , arm warmers, leg warmers, vests, complete team kits.

Turnaround time : 4-6 weeks for standard orders. Need it faster? Rush production is an option.

Best for : Startups entering the cycling apparel market. Small cycling clubs (10-30 members). Brands testing new designs before they scale up. Retailers who want private label cycling apparel but can't risk huge inventory buys.

Black Sheep Cycling shows you don't need big budgets to make quality custom bike wear .

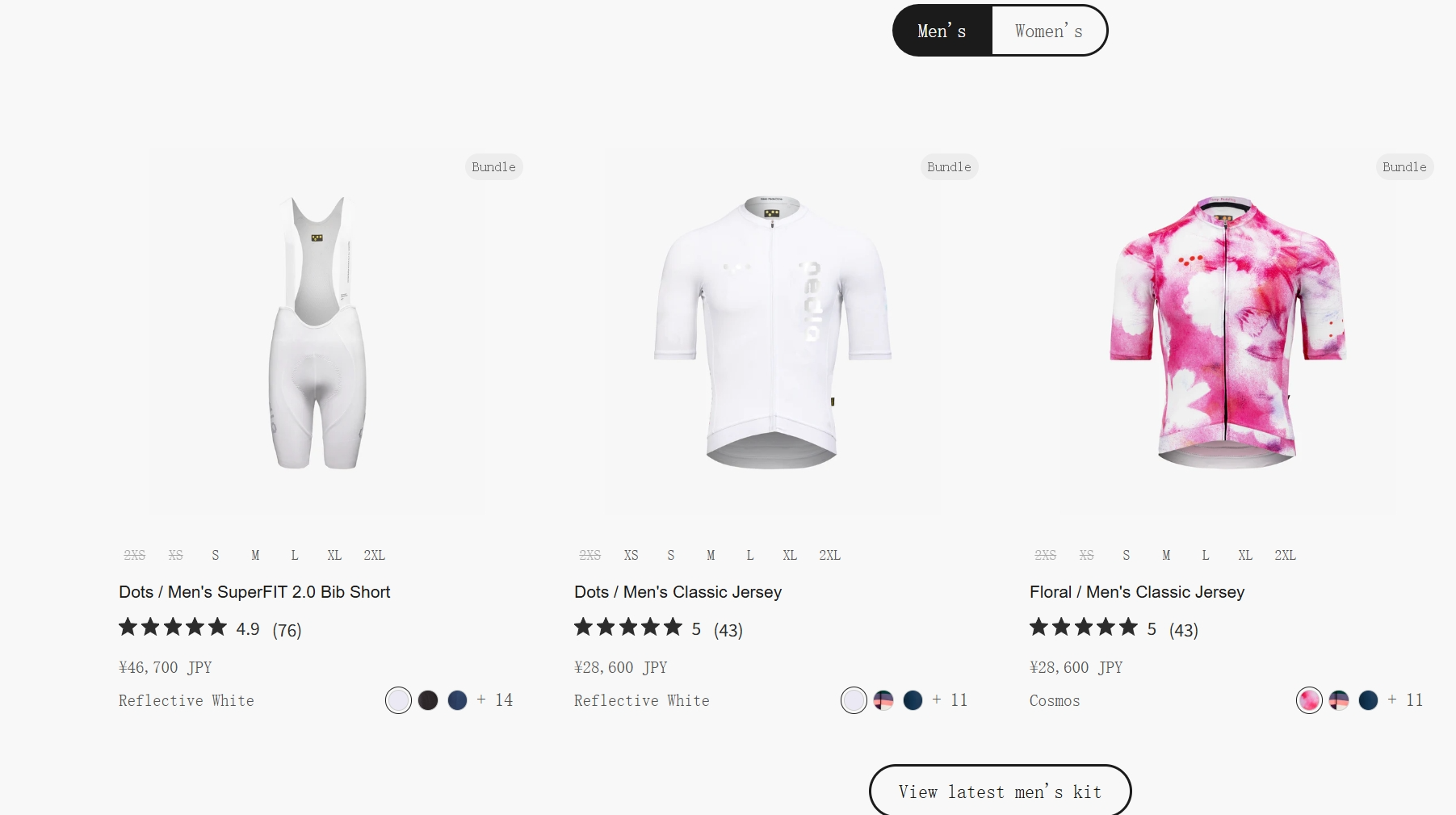

Pedla - Italian Luxury Fabrics with Low MOQ

Pedla runs out of Melbourne. Their focus is clear: Italian luxury fabrics with no huge order minimums. The custom program uses four-way stretch Italian microfiber and Elastic Interface chamois . These are the same materials in €300+ European race kits. Here's what sets them apart. No 100-unit minimum required.

Sizing goes from 4XS to 4XL. You get color samples before placing your order. Paid samples let you check fit and fabric quality first. Custom options? Classic Jerseys, SuperFIT Bib Shorts, Pro Jerseys, and SuperFIT 2.0 Bibs. Plus 30% off select add-ons—warmers, gloves, caps—for complete team kits.

Premium Products with Technical Precision

Pedla's summer line covers different riding styles. The Climba Jersey ($230 AUD) is super light. Aero microfiber mesh sleeves and chest panels boost airflow. The LunaLUXE Short Sleeve works all year. Need storage? The Roamer has two extra side pockets made with lightweight mesh.

Winter gear is tougher. The Thermal LS Jersey ($320 AUD) uses sun-blocking microfiber. It has heat-welded seams and silicone grip bands. The SuperFIT 2.0 Bib Tight ($390 AUD) works for cold rides. YKK auto-lock zippers keep things secure. Fabric pulls moisture away. Panels are built to breathe.

Best for : Cycling clubs that want Italian fabric quality. Companies gearing up their teams. Riders who want European performance cycling clothing with fast Australian service.

MAAP - Next-Gen Sustainable OEM Partner

MAAP sits where Melbourne design meets global manufacturing power. This premium cycling brand made its name on race-tested gear. Now they're opening their production network to select OEM & ODM cycling apparel partners.

Sustainability matters here. Over 70% of their materials come from recycled sources. They hold Bluesign certification—one of the toughest environmental standards in textile making.

The Melbourne design studio drives new ideas. Production scales through their Milan partnership with United Apparel Solutions. This dual-location setup gives you access to next-gen circular knitting tech. The same machines that make MAAP's $280 AUD Pro Bibs can produce your private label cycling apparel .

Premium Positioning with Environmental Edge

MAAP doesn't compete on price. They compete on performance and planet-positive production. Their technical cycling garments use advanced fabric treatments. You get moisture control. UV protection. Strategic compression zones. All while meeting strict environmental rules.

The market backs this approach. Recent data shows 55% of global consumers pay premium prices for green products. Cycling fans? They're even more committed to sustainable cycling apparel .

Best for : Established cycling brands ready to scale with premium positioning. Retailers targeting green-minded riders. Corporate clients who need top-tier performance cycling clothing that fits ESG goals. Brands willing to meet higher MOQs for cutting-edge bike clothing production Australia standards.

MAAP's OEM program isn't for everyone. It's for brands that refuse to compromise on quality or ethics.

Attaquer - Eco-Certified Performance Apparel

Attaquer built its reputation on one simple promise: race-level performance with zero environmental compromise. This Australian brand sources recycled Italian and Spanish fabrics only. Every jersey and bib short carries OEKO-TEX Standard 100 or bluesign certification. That's not marketing spin. Third-party labs verify that materials passed safety tests for over 1,000 harmful substances.

The All Day 2.0 Jersey shows this approach well. 90% recycled Polyamide, 10% Elastane —Italian fabric throughout. All materials carry OEKO-TEX certification. The All Day Parametric Jersey takes it further: 100% recycled Nylon with both OEKO-TEX Standard 100 and bluesign certifications. These aren't cheap eco-options. They're technical cycling gear that matches premium race equipment.

Multi-Fabric Performance Engineering

Attaquer skips single-fabric construction. The Race Jersey Mesh 01 combines three different materials. Lightweight 3D mesh covers shoulders and side panels. This gives you top-level temperature control and better aerodynamics. Weight? Just 116.4 grams for men's medium . The front and sleeves use Swiss hexagonal mesh that cuts skin contact points and improves air flow. The back uses rigid mesh that stops pocket sag under load.

Their Race Bib Short features 80% recycled Italian body fabric and high-compression Spanish knit. The leg structure is seamless with laser-cut edges. This cuts friction and improves aerodynamics. Weight: 191 grams with SPF 50+ protection and temperature range of 18–35°C+.

Best for : Performance-focused brands seeking sustainable cycling apparel with race-proven results. Retailers targeting eco-conscious riders who won't sacrifice speed. Teams needing certified safe materials that meet technical cycling gear specs.

Soomom - Italian Fabrics with UPF Protection

Soomom makes every fabric in Italy. No mixed sourcing. No cost-cutting substitutes. Pure Italian textile work runs through their entire cycling apparel line. The numbers prove it: UPF 50+ protection across every jersey.

The Pro Exclusive Jersey weighs just 97 grams in size small . The fabric? 85% Polyester, 15% Elastane with Bluesign certification . This goes beyond basic sun protection. You get medical-grade UV blocking in race-weight gear. It works well between 18°C to 30°C (64°F to 86°F) . Great for Australian summer rides.

Their All-Around Jersey uses 85% Polyamide, 15% Elastane . Moonlit, Abyss, and Inception colors carry Oeko-Tex certification . The All-Around Thermal Jersey suits winter riders: 58% Nylon, 32% Polyester, 16% Elastane . YKK zippers open smooth and reliable. They last.

Every jersey stretches, breathes, and dries fast. Italian fabric sourcing means no quality gaps. You get reliable technical cycling garments that protect your skin and perform hard.

Best for : Brands that need certified UV protection. Retailers who serve sun-aware cyclists. Teams wanting light performance cycling clothing with proven safety records. Australian shops looking for Italian fabric quality with verified sustainable cycling apparel certifications.

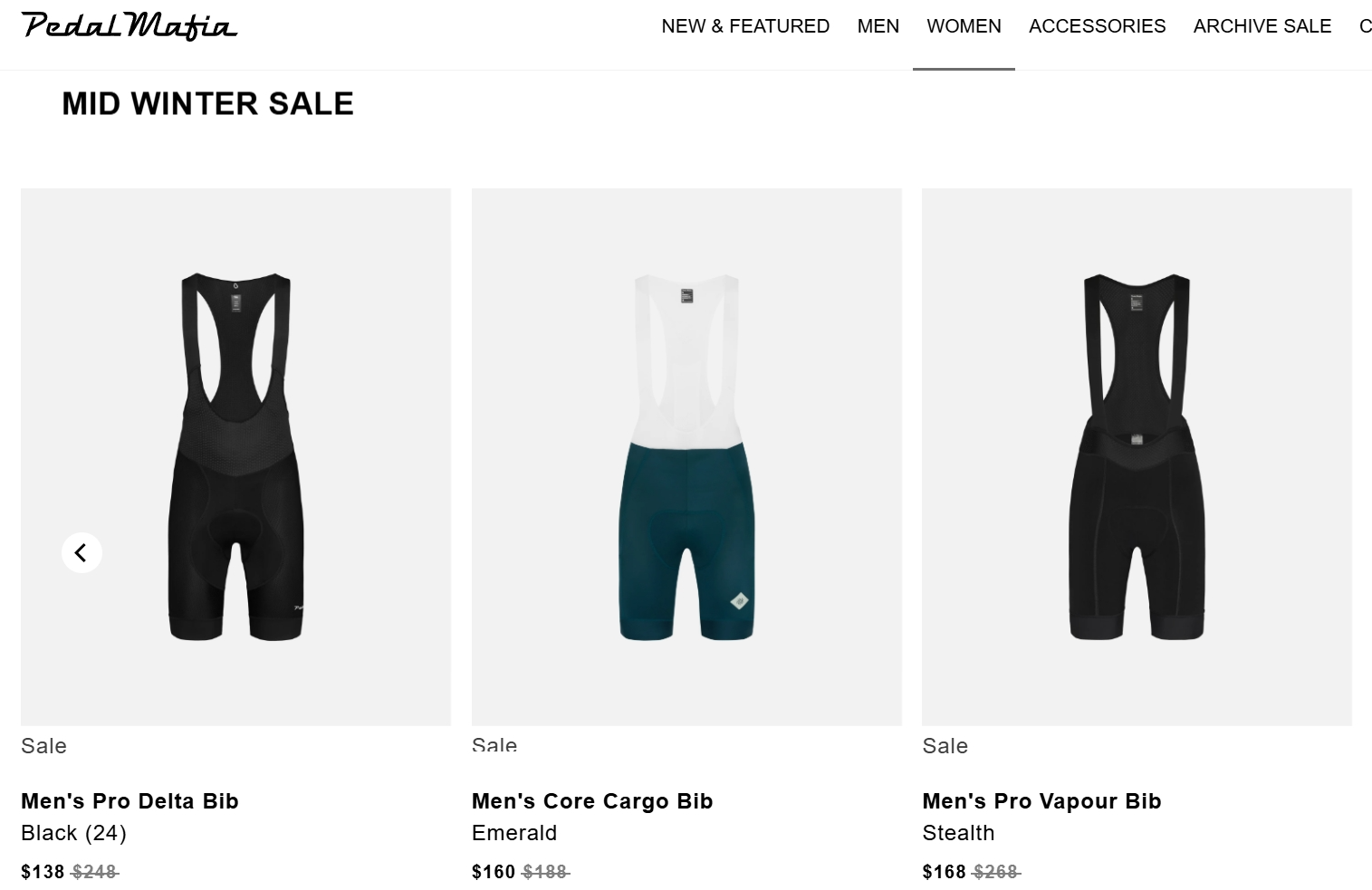

Pedal Mafia - Zero MOQ for Maximum Flexibility

Most wholesale cycling clothing manufacturers push you into bulk orders. Pedal Mafia ditches that rule. Zero minimum order quantity. Yes, zero MOQ . Order one custom jersey for yourself. Order five kits for your weekend group. Order fifty for your club. You get premium European materials. Production quality stays the same. Service level stays the same.

This Australian brand built its custom bike wear factory model around easy access. Riders design personal kits. Small cycling clubs (3-5 members) get full customization. Corporate teams order what they need. Event organizers create limited-edition race kits. The design editor gives you unlimited edits. No color restrictions. No design limits. No penalties for small quantities.

European Materials Without European Minimums

Pedal Mafia sources premium European fabrics for every custom piece. Italian knitted matte finish fabric goes into their PMCC bib shorts . The fabric gives race-level comfort. No stiff, plasticky feel like budget materials. Fit runs relaxed—size up for compression. Their Core collection hits the sweet spot: Watopia bibs at $168 USD , jerseys at $128 USD , base layers at $50 USD .

The tight fit works well. Good length in the torso. Breathable 3D mesh handles Australian heat. These aren't cheap training kits. They're performance cycling clothing you'll grab every ride.

Production timeline : 4-6 weeks from design to delivery. Delays happen sometimes (supply chain issues). Pedal Mafia tells you right away.

Shipping : DHL and UPS worldwide. Free US shipping over $99 (excludes custom orders). Tracking comes within 48 hours.

Best for : Solo riders wanting unique custom bike wear . Small cycling clubs (under 10 members). Event organizers creating limited-run kits. Teams that re-order often and want locked pricing. No MOQ pressure.

The crash replacement program adds value. Accident damage? You get discounted replacements. Manufacturing defects? Warranties vary by product. Pedal Mafia stands behind their work.

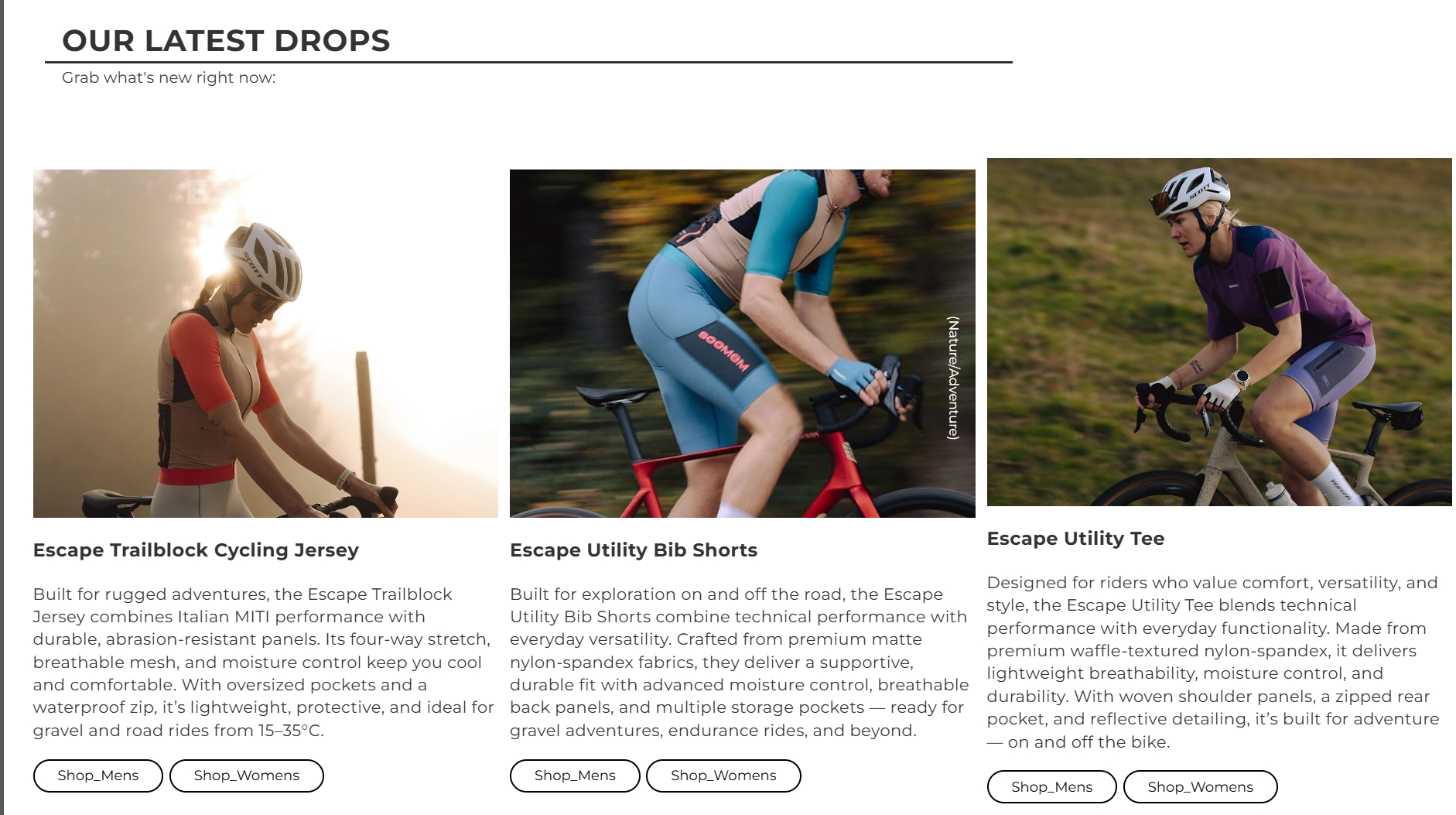

Velocio Australia - Design-First European Production

Velocio Australia won't use white-label templates. Each piece starts fresh. They create original patterns. They source custom fabrics. No shortcuts exist here. This design-first method makes them stand out in Australia's cycling apparel market.

Their European factory partner sticks to strict EU labor guidelines . Workers get fair wages. They work in safe conditions. Pregnant workers receive protection. The facility uses 80% renewable energy . Some mills collect ocean waste . They turn it into pellets. Then they spin it into performance yarn.

Built Through Thousands of Riding Hours

The team logs thousands of hours on bikes each year testing designs. They call it "design, ride, repeat." CEO Brad Sheehan spotted a gap in women's performance gear. Velocio started with 20+ women's styles and just 2 men's options . Both ranges are now equal. Each has its own fit standards.

Head of Sales Olivia Dillon won Rás na mBan three times . No other rider has won it that many times. Her racing know-how shapes what they make.

Australia's current jerseys use 100% recycled fabrics . The full range gains more recycled and bio-based materials each year. Biodegradable packaging goes out with every order. Gear that lasts means you replace it less.

Custom team program : They skip templates. You get personal fit sessions instead of generic size charts. Your feedback shapes the design.

Best for : Teams that want European production quality. Brands that need sustainable cycling wear backed by proven performance. Riders who choose gear that lasts over gear that's cheap.

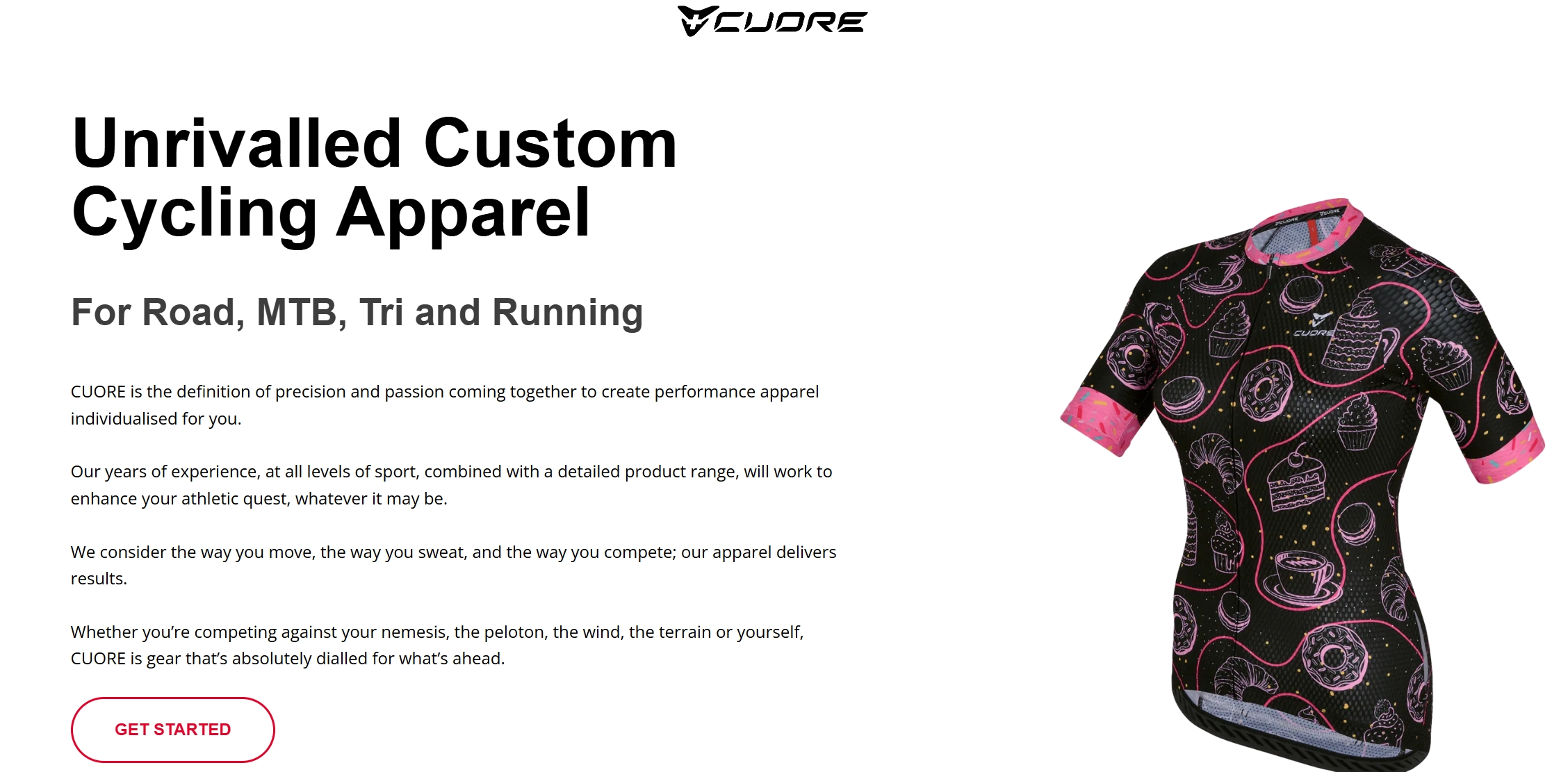

Cuore Australia - Swiss Precision Custom Expertise

Cuore brings Swiss engineering to Australian cycling teams. The brand runs from two locations. Swiss headquarters handle R&D, pattern work, and production rules. The Australian office manages sales, design help, and order handling for AU/NZ clubs.

This setup gives you precision. No long European wait times. You get Swiss-made pattern blocks and fit libraries . Your Australian contact runs sizing sessions and handles after-sales support in your area. Orders ship faster. You pay in AUD. Talk to your contact in your timezone.

Computer-Controlled Precision Manufacturing

Cuore builds quality into every garment. Computer-controlled cutting keeps panel sizes the same across every size. Graphics line up at seams. Laser-cut leg grippers stop fraying. Wide integrated silicone print takes the place of stitched elastic bands.

The seam work sets them apart from budget brands. Flatlock or 4-needle stitching at key joins cuts down bulk. It reduces skin rubs too. Top-tier speed suits get bonded and taped seams in high-drag zones. Air flows better. Drag goes down.

Multi-fabric construction beats Australia's heat. High-compression panels (20%+ elastane) support leg muscles. Mesh panels in underarms and back zones pump in fresh air. Main body fabrics carry UPF 30-50+ ratings . This matters for Australian UV levels.

Full-coverage sublimation printing goes onto white technical polyester. CMYK process gives you unlimited colors. Detailed logos add zero weight. Colors stay bright after many washes.

Team Customization Process

Cuore's workflow handles team orders:

Best for : Corporate cycling teams that want Swiss quality with Australian service. Large clubs (50+ members) that need exact fit across many sizes. Brands that want technical cycling gear with laser-cut finishing and UPF protection.

OEM & ODM Cycling Apparel Manufacturers Comparison Table

Comparing 13 cycling apparel manufacturers takes hours of research. I've packed all the key data into one table. You'll see MOQ requirements. Production times. Key tech. Certifications. No more guesswork.

Manufacturer | Location | MOQ | Delivery Time | Price Range | Key Technologies | Certifications | Best For |

|---|---|---|---|---|---|---|---|

Lameda (Hangzhou Lameda Sports Ltd) | Hangzhou, China (exports 100+ countries) | Low | 3 weeks custom | Annual sales $9.44M | Eco-Jerseys (recycled nylon); custom design | N/S | Sustainable high-performance jerseys/bib shorts; ODM custom |

Runtowell Ltd | Guangzhou, China | Low for small teams | Fast small orders | Competitive/low | Standard production | N/S | Quick production, cost-effective custom bike wear |

Monton Sports | China (est. 2009) | Low | Fast small orders | Competitive | 3D design confirmation; private label cycling apparel | N/S | Stylish kits (216 men's, 181 women's items) |

Darevie | China | N/S | N/S | Competitive factory | High-capacity production | N/S | Big volume (30,000 jerseys/month); full range |

JaceApparel | China | Low (small bulk test) | N/S | N/S | Quality control focus | N/S | Bulk customization, market testing orders |

Santic | Xiamen, China (2005) | N/S | N/S | N/S | Ergonomic designs; innovation materials | N/S | |

CCN Sport | Hong Kong/Shenzhen (2005) | N/S | N/S | N/S | Performance-oriented; team customization | N/S | Global shipping, 20+ teams served |

JRD Cycling Ltd | Beijing/Dongguan (1994) | 100-200 | Fast | Mid-range/cost-efficient | Robotic cutting; semi-automated sewing | ISO 9001, SGS | B2B cycling kit manufacturers ; turnkey logistics |

Taxon | China | 50 pieces | 7-10 days sampling | N/S | Advanced R&D eco-processes; in-house printing | ISO 9001 | Aero jerseys, bibs; full labels/packaging |

LeelineSports | China | Low | 7-10 days sampling | N/S | End-to-end customization | ISO | Race jerseys, gilets; cycling jersey production |

ECYKER | China | N/S | N/S | N/S | Seamless bonding; laser-cut hems; 3D fit | N/S | Race-fit jerseys, compression bibs |

BOHANG | China | N/S | N/S | Competitive | Vertical integration | N/S | Big capacity (2M+ pieces/year); entry-level kits |

Cwing Sport | China | N/S | 7 days samples | N/S | Custom pattern-making | N/S | Mesh jerseys, high-compression bibs |

N/S = Not Specified in public sources. Contact manufacturers for current 2025 pricing and MOQ details. Production capacities differ a lot. Darevie handles 30,000 units per month. BOHANG exceeds 2 million pieces per year.

Alternative: International OEM Partner - Berunclothes

Australian cycling apparel manufacturers deliver quality. But let's talk numbers. Local production costs run 40-60% higher than Asian alternatives. Berunclothes fills this gap—a Guangzhou-based cycling apparel specialist. They've become the go-to OEM cycling apparel partner for cost-conscious Australian brands.

Here's what sets them apart: 10-piece minimum orders . Most Chinese factories laugh at orders under 500 units. Berunclothes built their entire model around easy access. Testing a new design? Launching a limited club kit? You don't have to gamble $15,000 on unproven inventory.

European Components at Asian Pricing

The factory stocks 300+ cycling-specific patterns . Road jerseys , bib shorts , gravel kits , MTB apparel —every category you need. They use the same premium parts as $200+ Australian brands. Elastic Interface chamois pads (the Italian standard). Miti Italian fabrics . YKK zippers throughout.

Production speed? Faster than most competitors. Standard custom cycling jersey production takes 25-35 days from approved artwork. Need a rush order? Add 15-20% to the cost. This cuts that timeline by a week.

Pricing structure works like this: Entry-level cycling jerseys start at $18-25 USD per unit (10-50 pieces). Scale to 200+ units. You're looking at $12-18 USD. Premium bib shorts with Italian chamois run $35-45 USD for small batches. Volume orders drop to $25-35 USD.

Quality control matches what you'd expect from Australian cycling apparel makers. Pre-production samples arrive before bulk orders. Inspections during production catch issues before they spread. Final QC checks happen before shipping.

Australian logistics : They ship direct to Sydney, Melbourne, Brisbane. Sea freight takes 30-40 days (cheapest option). Air freight takes 7-10 days (3-4x the cost). DDP (Delivered Duty Paid) pricing available. You pay one number. They handle customs.

Best for : Startups testing market fit without crushing upfront costs. Established brands adding private label cycling apparel lines. Retailers who need wholesale cycling apparel margins that work. Clubs ordering 50-100 custom kits each year.

Contact: servicecycling@outlook.com for current pricing and production slots.

Conclusion

Finding the right OEM & ODM cycling apparel manufacturers in Australia doesn't need to be complicated. You now have ten trusted partners. Each brings different strengths. SCODY offers Australian-made sustainability. Pedal Mafia provides zero-MOQ flexibility. Berunclothes gives you global production power.

Match your business needs to what each OEM &ODM cycling apparel manufacturer does best. Starting a premium brand with small batches? Pedla or Ventou give you European quality. MOQs stay low. Growing fast and need eco-friendly options? MAAP and Attaquer have eco-certified production ready. Want high-volume production at good prices? Berunclothes brings serious manufacturing capacity. Technical standards stay high.

The Australian cycling market will grow 7.2% each year through 2027. Your manufacturing partner choice today sets your market position tomorrow. Price sheets don't tell the whole story. Look at production timelines. Check fabric sourcing transparency. Ask about post-production support.

Pick three cycling apparel manufacturers from this list to start. Get samples sent to you. See how fast they respond to questions. That next call might create the partnership that takes your cycling brand from idea to winner's podium. The race is on—act now.