Finding the Right Sports Bra Manufacturer in USA? Here's What Really Matters

The ultimate guide to choosing sports bra manufacturers for the American market—backed by 30 years of manufacturing expertise and real data from 500+ successful brand partnerships.

Understanding the US Sports Bra Market

Before you choose a manufacturer, you need to understand what makes the American market unique.

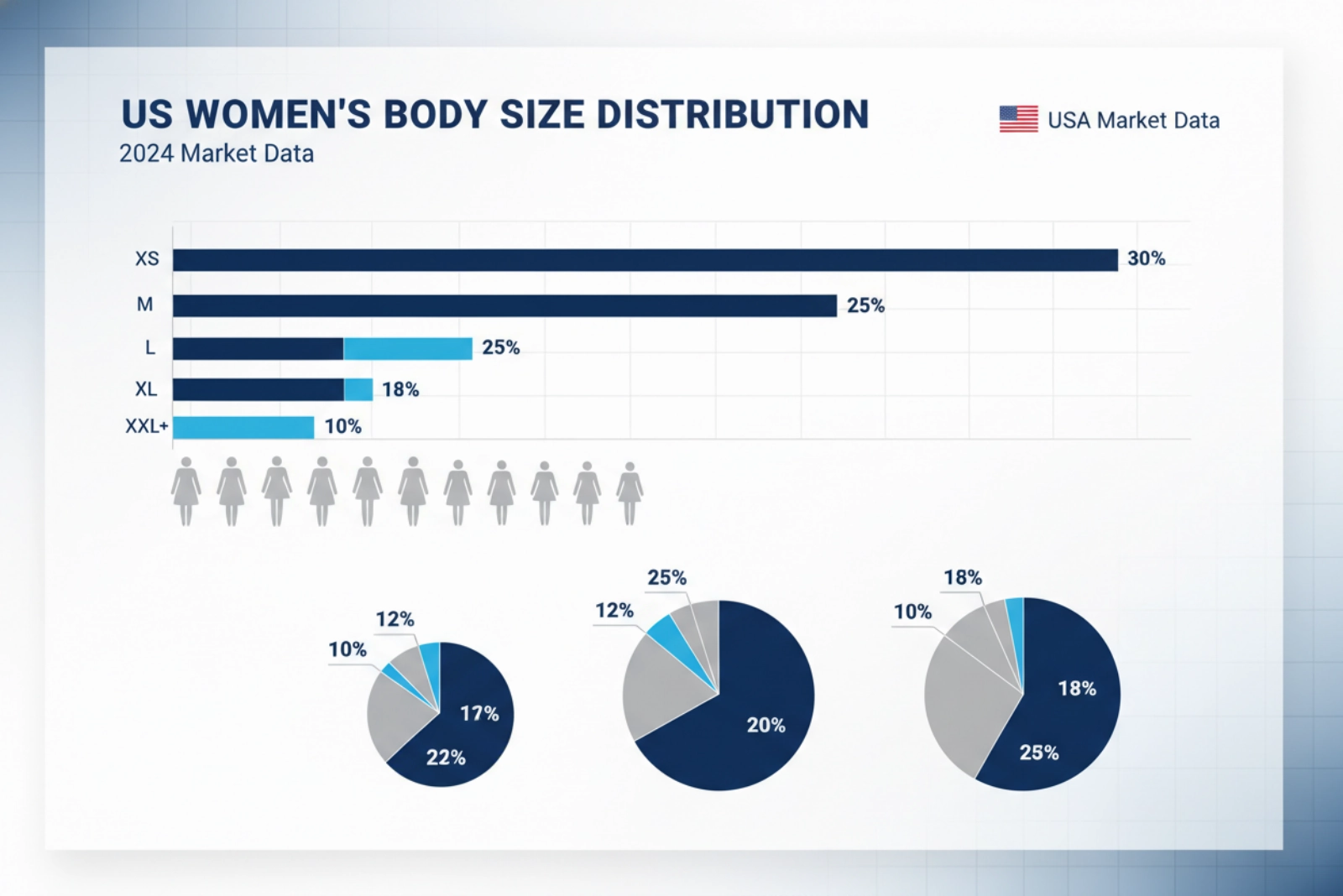

US sports bra market growing at 6.8% annually, driven by athleisure trend and fitness boom

Two-thirds of American women wear size 14+, making size inclusivity non-negotiable

Majority of US consumers actively seek eco-friendly materials and ethical production

Why US Market Requirements Are Different

| Requirement | US Market Standard | Why It Matters |

|---|---|---|

| Size Range | XS to 3XL+ (A-DDD cups minimum) | 67% of American women wear plus sizes—limited range means lost sales |

| Testing Standards | AATCC compliance required | Federal regulations and major retailer requirements (Target, Amazon, Walmart) |

| Lead Time | 45-60 days from sample approval | Fast fashion cycles and seasonal demands require quick turnaround |

| Sustainability | Eco-friendly materials & certifications | 58% of consumers prefer sustainable brands—it's a competitive advantage |

| Compliance | CPSIA, Prop 65, retailer-specific | Non-compliance can result in product recalls and legal liability |

5 Key Standards for Evaluating Sports Bra Manufacturers

Here's what separates exceptional manufacturers from the rest—based on real manufacturing data and US market requirements.

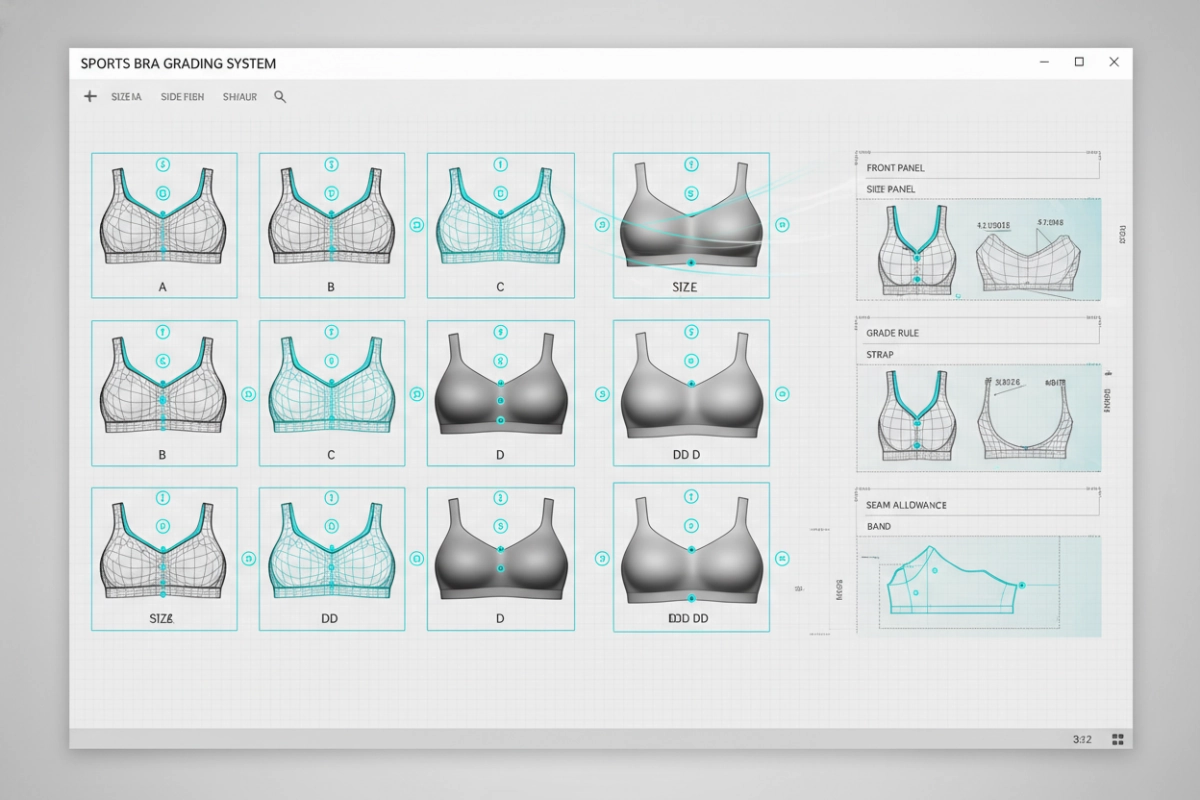

1. Pattern Engineering Expertise

What to Look For:

- 3D pattern design capability using CAD software

- Grading expertise for minimum 8-10 size range

- Fit testing with diverse body types and measurements

- Clear adjustment iteration process with feedback loops

- Native plus-size pattern blocks (not just scaled-up)

Red Flags to Avoid:

- Limited to only 3-4 standard sizes

- No documentation of fit testing protocols

- Cannot show pattern adjustment examples

- Relies solely on manual pattern making

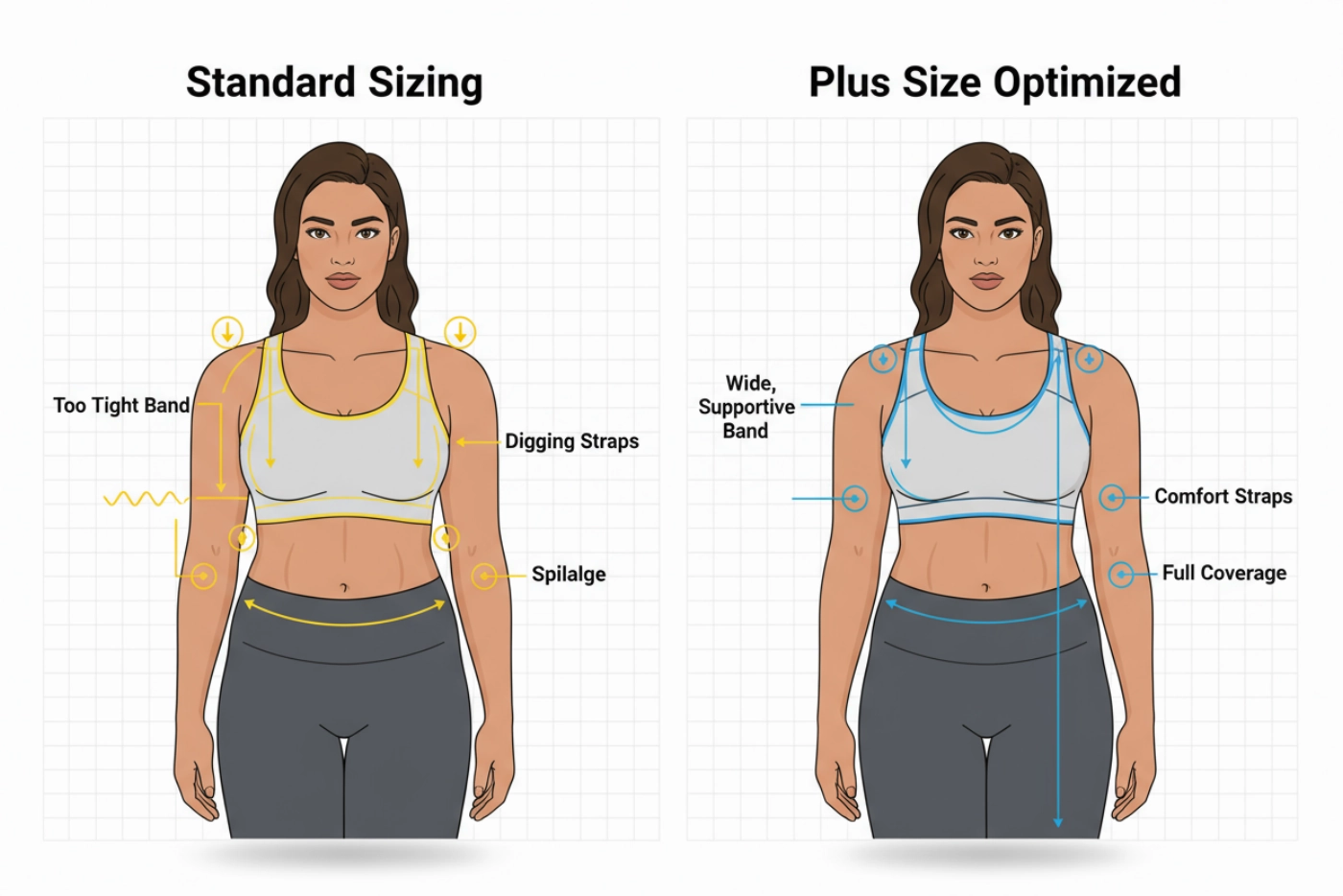

2. Size Range Coverage (Size Inclusivity)

Essential Requirements:

- Native plus-size pattern blocks with proper proportions

- Cup size range: A to DDD (or beyond) minimum

- Band size range: 32 to 44+ inches

- Specialized fit models for testing each size

- Documented grading rules that account for body shape variation

Warning Signs:

- Plus sizes are just "scaled-up" standard patterns

- Cannot demonstrate plus-size fit testing

- Limited cup size options

- No understanding of US body diversity

3. Performance Testing Protocols (AATCC Standards)

Critical Testing Standards:

- AATCC 135 (Dimensional Stability) - Will it shrink after washing?

- AATCC 61 (Colorfastness to Laundering) - Will colors fade or bleed?

- ASTM D4966 (Abrasion Resistance) - Will it wear out quickly?

- ASTM D4964 (Pilling Resistance) - Will fabric ball up over time?

- Compression Testing - Does it maintain support during activity?

- Moisture-Wicking Performance - Does it actually keep you dry?

Verify Their Capability:

- Ask for recent test reports (with dates)

- Request lab equipment inventory list

- Verify third-party audit certificates

- Check testing frequency (every production run vs random)

Red Flags:

- Vague on testing procedures

- No in-house lab or third-party certification

- Cannot provide recent test reports

- "Trust us, we've never had problems"

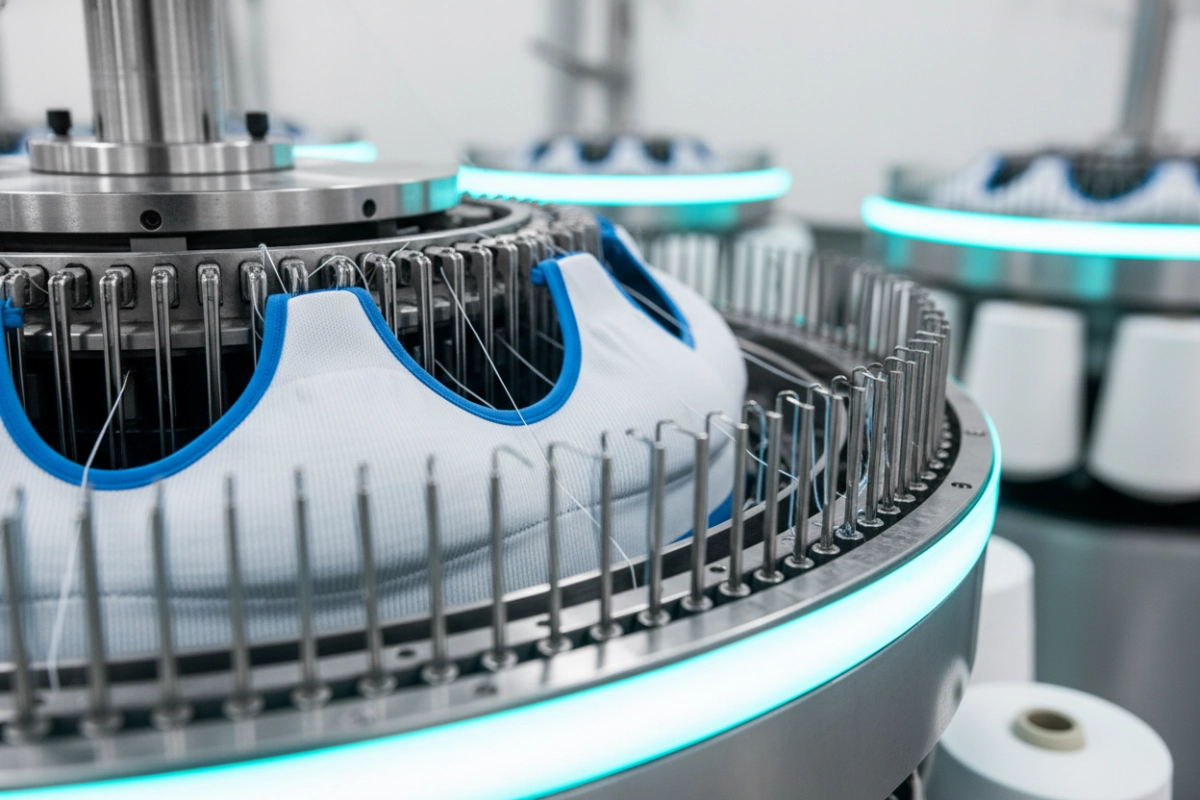

4. Proprietary Technology & IP Protection

Technologies to Look For:

- Seamless knitting technology for zero irritation

- Advanced moisture-wicking fabric innovations

- High-impact support systems for larger cup sizes

- Antimicrobial treatments that withstand washing

- Patent documentation and IP protection policies

Questions to Ask:

- Do you hold any patents for sports bra construction?

- What proprietary processes differentiate you?

- How do you protect client designs and IP?

- Can you provide NDA before sharing designs?

5. Quality Control & Compliance Systems

US Market Compliance Essentials:

- CPSIA (Consumer Product Safety Improvement Act) - Federal requirement

- California Prop 65 - Chemical disclosure requirements

- Retailer-Specific Standards - Target, Walmart, Amazon each have unique requirements

- Ethical Certifications - WRAP, BSCI for labor standards

- Environmental Standards - Oeko-Tex, GRS, GOTS for sustainability claims

4-Point QC System:

- Pre-Production - Sample approval with detailed spec sheets

- DUPRO (During Production) - In-line inspection at 30-50% completion

- FRI (Final Random Inspection) - AQL 2.5 standard minimum

- Loading Inspection - Verify packaging and quantities before shipping

Certifications to Verify:

- ISO 9001 (Quality Management System)

- WRAP or BSCI (Ethical Production)

- Oeko-Tex Standard 100 (Textile Safety)

- Third-party audit readiness

Free Decision-Making Tools

Download our manufacturer evaluation scorecard and use these comparison frameworks to make the right choice.

Manufacturer Evaluation Scorecard

Rate each manufacturer using this framework. Anything below 60 points is a red flag.

| Criteria | Weight | Excellent (5pts) | Good (3pts) | Poor (1pt) | Score | Notes |

|---|---|---|---|---|---|---|

| Pattern Tech | 25% | 3D design + 10+ sizes | Basic grading capability | Limited sizes only | ___ | ___ |

| Size Range | 20% | XS-4XL, A-DDD cups | Standard size range | 3-4 sizes only | ___ | ___ |

| Testing | 20% | Full AATCC + in-house lab | Basic compliance testing | No testing docs | ___ | ___ |

| Technology | 15% | Patented processes | Modern equipment | Outdated technology | ___ | ___ |

| Quality Control | 20% | 4-point inspection + audits | Basic QC process | Inconsistent quality | ___ | ___ |

| TOTAL SCORE (out of 100) | ___ | ___ | ||||

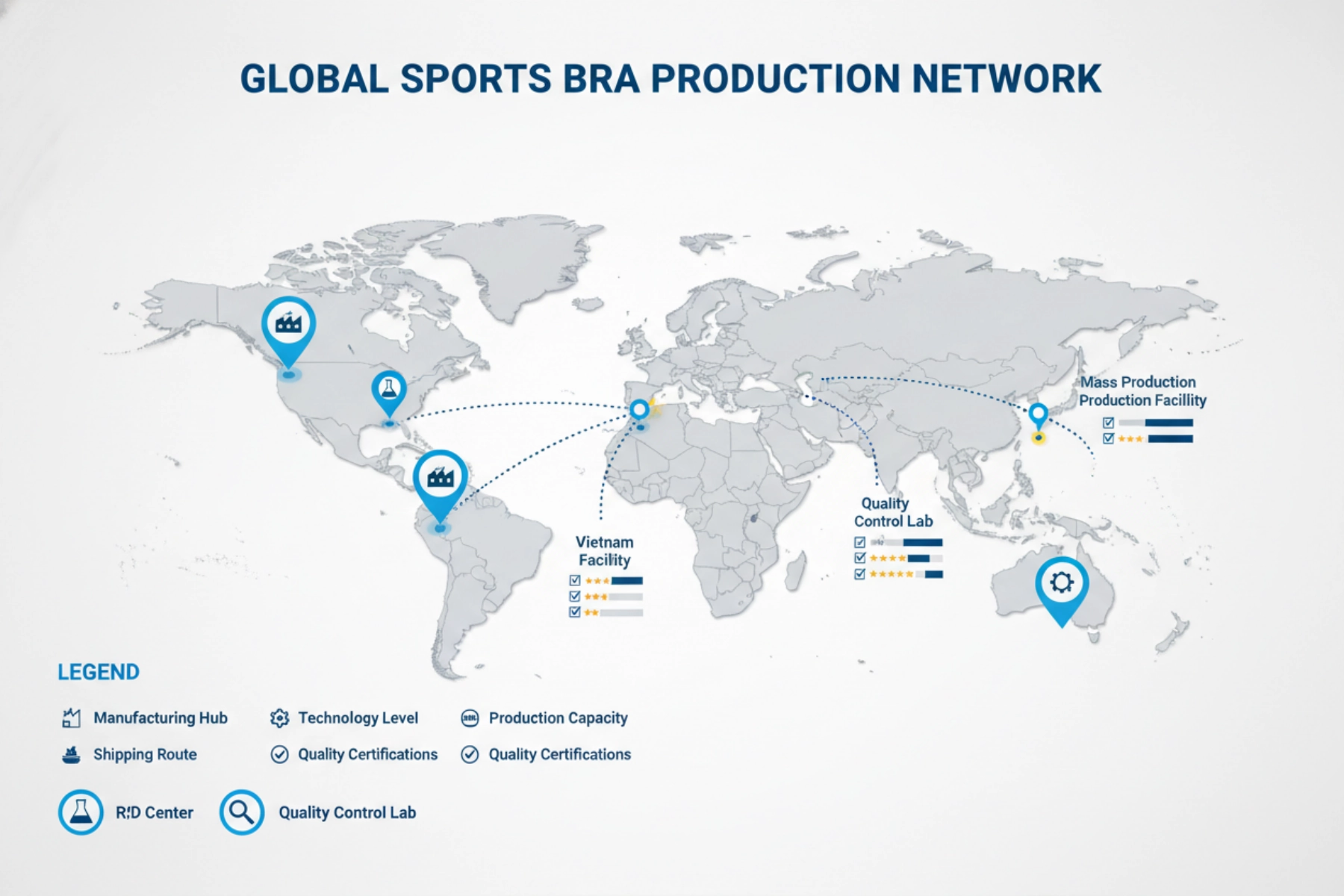

Manufacturer Type Comparison

Chinese OEM Factories

- Cost-effective pricing (30-50% lower)

- Scalable production capacity

- Advanced technology and equipment

- Flexible MOQ for growing brands

- Longer lead times (45-60 days)

- Communication time zone differences

- Quality variance if not properly vetted

Established brands, mid-to-large orders (500+ units)

US Domestic Factories

- Fast turnaround (2-3 weeks)

- Easier communication (same time zone)

- Lower shipping costs

- Made in USA branding

- 3-5x higher unit cost

- Limited production capacity

- Higher MOQ requirements

Small batches, quick market testing, premium brands

Offshore Low-Cost Factories

- Lowest unit pricing

- Very flexible MOQ

- Significant quality risks

- Ethical labor concerns

- Limited technical capabilities

- Poor communication

- No recourse for problems

Only for ultra-low-budget startups willing to accept risks

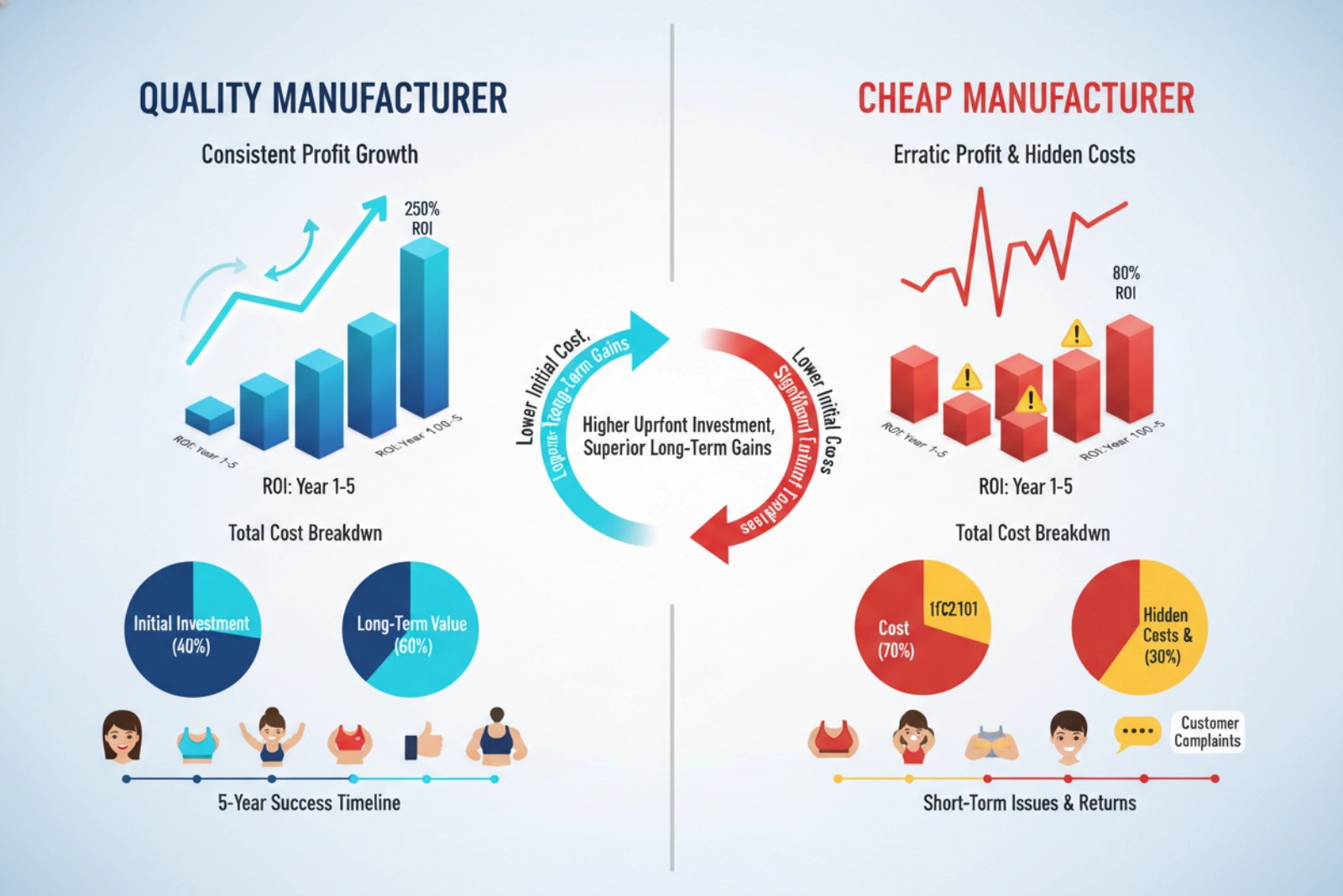

True Cost Calculator: Cheap vs Quality

Unit price is just the starting line. Here's what you actually pay when you factor in defects, returns, and lost customers.

Scenario A: "Cheap" Factory

Scenario B: Quality Manufacturer

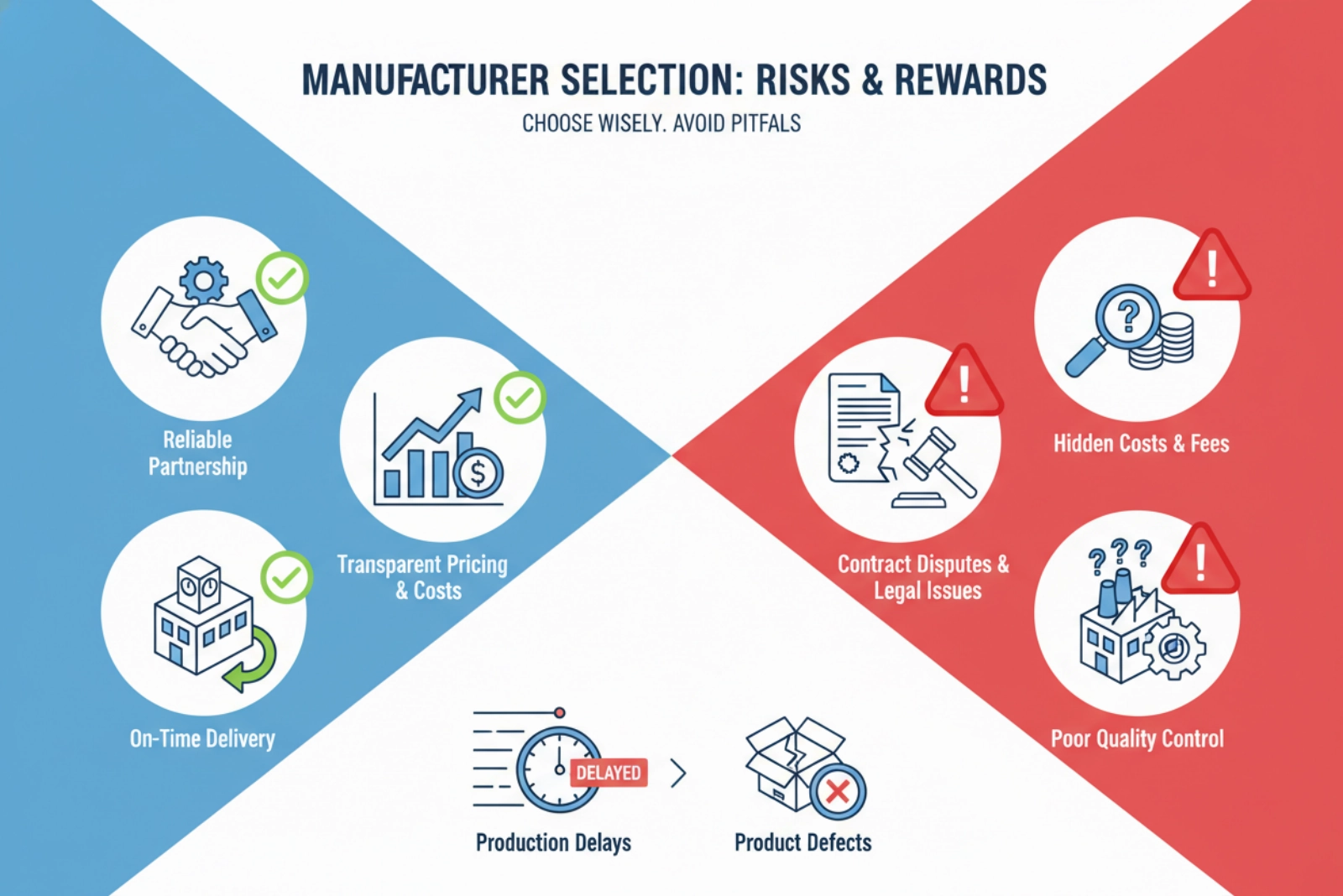

Avoid These Common Supply Chain Traps

Learn from the mistakes others have made. Here are the red flags to watch for.

🚩 Red Flag #1: "We can match any price"

Why it's risky: Quality shortcuts, hidden costs, bait-and-switch tactics

What to do: Ask for detailed cost breakdown. If they can't explain how they're cheaper, there's a reason.

🚩 Red Flag #2: No physical samples before bulk

Why it's risky: Huge gap between spec sheets and reality—you'll discover problems when it's too late

What to do: Insist on pre-production samples with full spec testing. No exceptions.

🚩 Red Flag #3: Vague on certifications

Why it's risky: Compliance issues, retailer rejection, potential legal liability

What to do: Request certification copies and verify them online. Certificates on the wall mean nothing.

🚩 Red Flag #4: Poor communication responsiveness

Why it's risky: Production delays, misunderstandings, unresolved problems

What to do: Test response time during negotiation. If they're slow now, imagine during production.

Factory Audit Checklist

If you're serious about a manufacturer, visit in person. Here's what to inspect:

- Number of production lines and machines

- Daily output capacity (units per day)

- Current order backlog and lead times

- Peak season vs slow season capacity

- Ability to scale for larger orders

- Dedicated QC team and inspection points

- AQL standards and defect rate tracking

- Pre-production sample approval process

- In-line inspection procedures (DUPRO)

- Final random inspection protocols (FRI)

- Corrective action procedures for defects

- Worker safety equipment and protocols

- Working hours and overtime policies

- Wage levels and payment timeliness

- Dormitory conditions (if applicable)

- WRAP, BSCI, or similar certifications

- Visible compliance notices and policies

- CAD/CAM software for pattern design

- Automated cutting equipment

- Specialized machinery (seamless knitting, bonding)

- Testing laboratory and equipment

- Equipment maintenance and upgrade schedule

- Dedicated sample development team

- Sample turnaround time (typically 7-15 days)

- Pattern making and grading expertise

- Fit model availability for testing

- Fabric library and sourcing network

- Fabric and trim storage conditions (temperature, humidity)

- Inventory management system

- Supplier verification and approval process

- Material testing before production

- Traceability of materials (batch tracking)

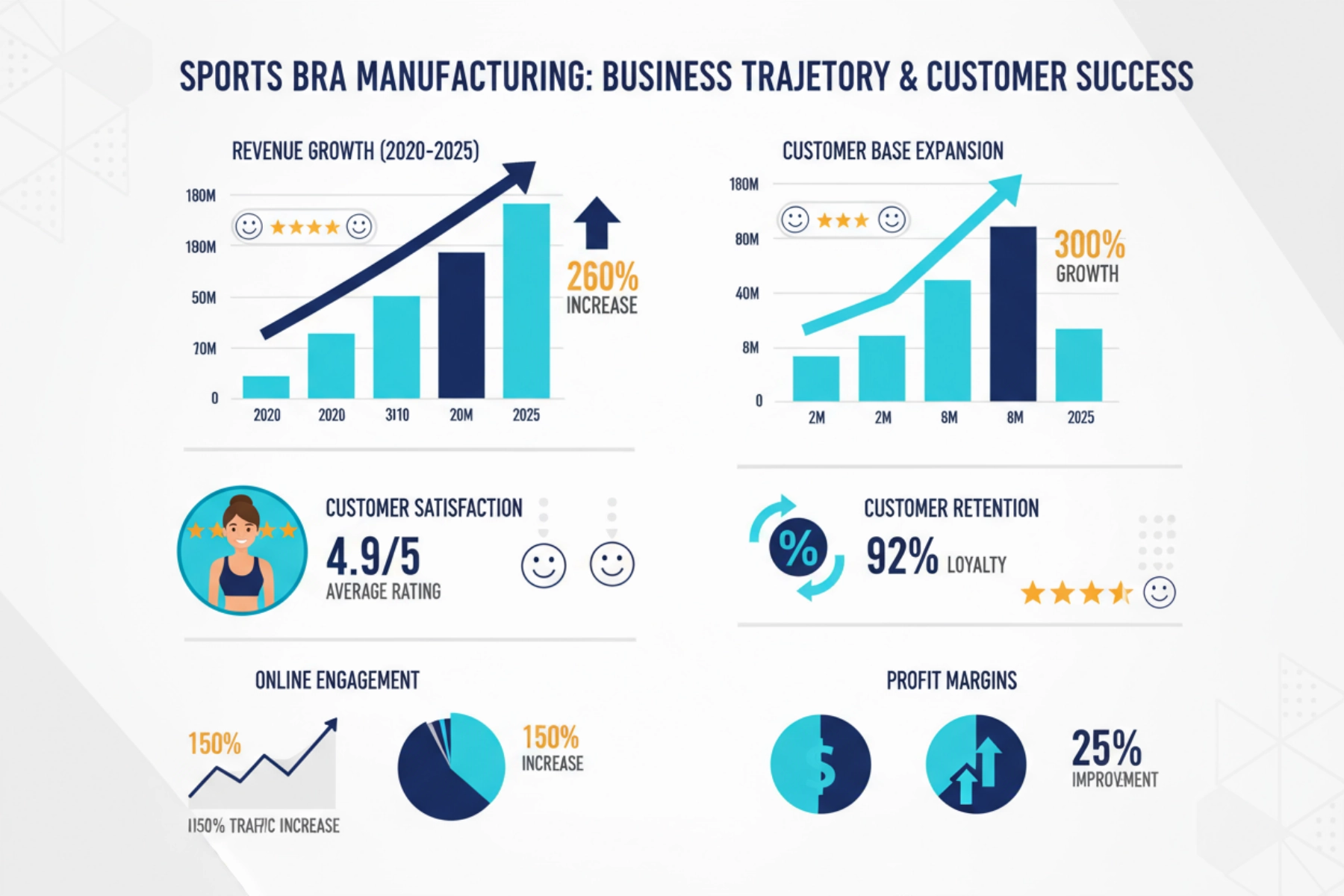

Real Success Stories

How brands found the right manufacturer and transformed their business.

DTC Yoga Brand Expands to 12-Size Range

A Los Angeles-based yoga wear startup came to us frustrated. Their previous manufacturer couldn't handle their size-inclusive vision—anything beyond XL came back with fit issues. Returns were climbing, and negative reviews were hurting growth.

- Needed 12-size range (XS to 3XL)

- Plus-size fit accuracy critical

- MOQ flexibility for market testing

- 18% return rate killing margins

- Developed native plus-size pattern blocks

- 3 rounds of fit testing with diverse models

- Started with 500 pcs/design for testing

- Implemented 4-point QC system

- 96% fit satisfaction rate

- Return rate dropped to 2.1%

- Expanded to 8 SKUs within 6 months

- Now a 3-year partnership

Amazon FBA Seller Cuts Returns by 88%

An Amazon seller was losing money on returns—18% return rate due to sizing inconsistencies from their previous supplier. With Amazon's strict seller metrics, they were at risk of losing Buy Box eligibility.

- 18% return rate eroding profits

- Needed AATCC compliance for Brand Registry

- Fast replenishment cycles required

- Negative reviews impacting rankings

- Implemented rigorous 4-point QC system

- AATCC testing for every colorway

- Reduced lead time to 45 days

- Standardized size spec sheets

- Return rate dropped to 2.3%

- Amazon Choice Badge earned

- 3x reorder volume within 12 months

- 4.7-star average rating

Success Metrics from Our Partner Brands

Frequently Asked Questions

Real answers to questions we hear every day from brands choosing manufacturers.

Ready to Find Your Perfect Manufacturing Partner?

Get your free Manufacturer Evaluation Kit—includes scorecard, US market data report, and factory audit checklist.

Prefer to talk first?

Schedule a 30-Min Consultation