Finding the right yoga apparel manufacturer in Asia feels like a maze. You're juggling minimum order quantities and quality concerns. Plus, there's the real fear that your samples came from a different factory than your bulk order.

The stakes are high. Choose well, and you get a reliable partner who scales with your brand. Choose poorly, and you're stuck with 5,000 leggings that pill after one wash.

I've worked with Asian manufacturers for a decade. I've seen spectacular wins and expensive failures. From this, I've identified eight standout factories that deliver on quality, ethics, and export reliability.

Testing your first 200-piece order as a startup? Or ready to commit to 50,000 units as an established retailer? This guide breaks down each manufacturer's sweet spot. You'll learn about Berunclothes' custom design strengths and JASAN Group's massive production capacity. Match your business needs with the right production partner. Skip the expensive trial-and-error phase.

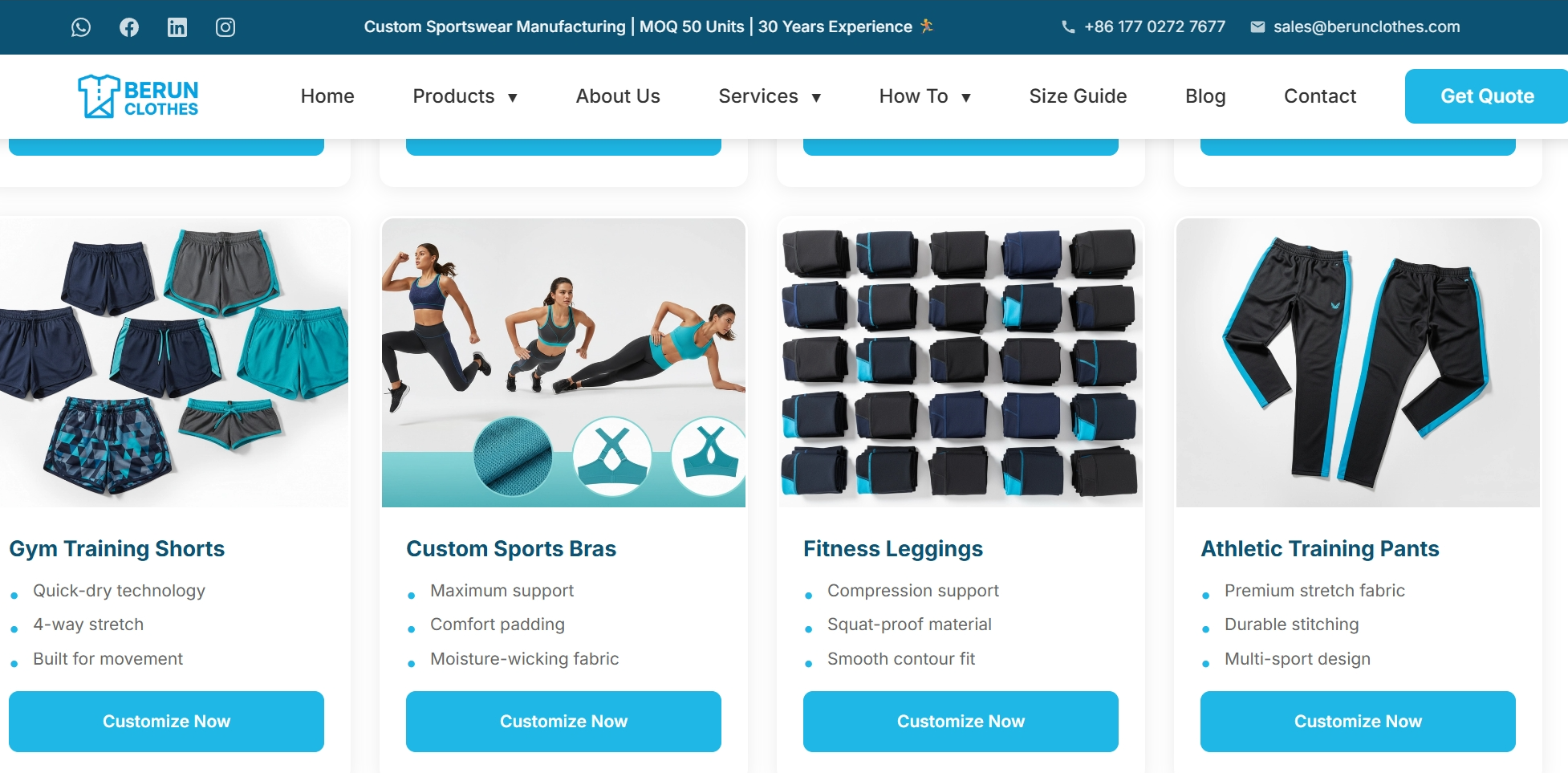

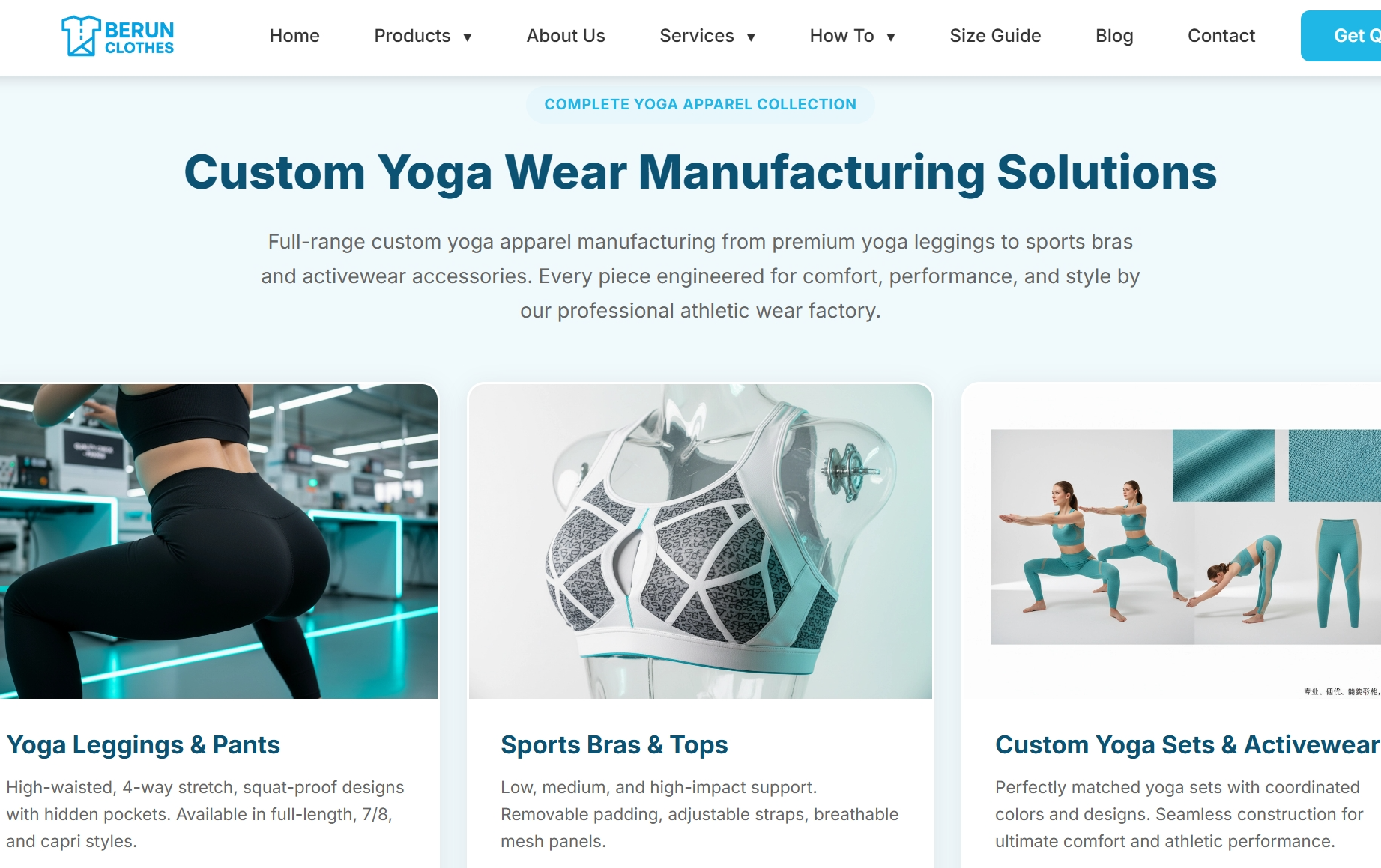

1. Berunclothes: Best for High-Quality Custom Yoga Apparel Manufacturing

Berunclothes built their reputation on one core principle: custom yoga apparel that performs under pressure. Not marketing promises. Real fabric engineering tested through 300% stretch cycles and hot yoga sessions.

This Chinese yoga apparel manufacturer combines three decades of textile know-how with modern athletic wear needs. They serve yoga brands and studios that refuse to compromise on quality but can't commit to 10,000-piece minimums from larger factories.

Why Emerging Brands Choose Berunclothes

The MOQ advantage changes everything. Start with just 50 units per design . Test your market. Validate your patterns. Scale up at your own pace—not on a factory's schedule.

Most activewear manufacturers see small orders as nuisance work. Berunclothes built their entire operation around flexible production runs. Order 50 pieces this month. Then 500 next quarter. Then 10,000+ once your Kickstarter campaign takes off. Quality stays the same. Priority treatment stays the same.

Speed matters for building momentum. Their sampling timeline runs 7-10 days for yoga-specific pieces. Submit your tech pack on Monday. Get your physical sample by the following week. Compare that to the industry standard of 3-4 weeks. Brands racing toward launch windows choose them for this reason.

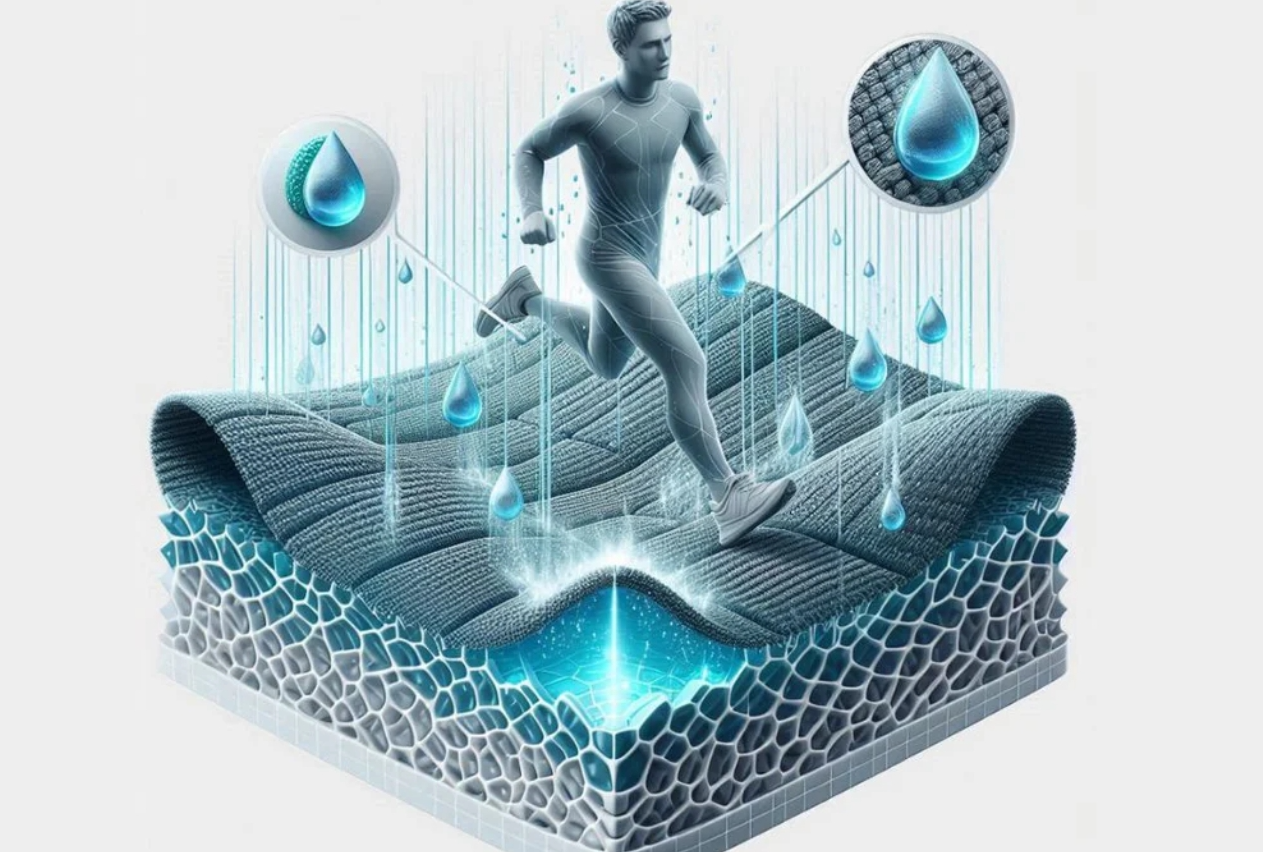

The Fabric Technology That Works

Here's where technical specs meet real yoga practice. Berunclothes engineers their four-way stretch fabrics to handle 300% stretch with instant recovery. Translation? Your leggings bounce back to their original shape after downward dog. After crow pose. After that tough vinyasa sequence your instructor loves.

Squat-proof construction is standard. Their high-density knitting process gets tested at maximum stretch points. Every fabric batch must stay opaque during deep squats and forward bends. Nothing kills a yoga brand faster than customers finding transparency issues mid-class.

The moisture-wicking system pulls sweat away in seconds. This is crucial in hot yoga environments. Cheap fabrics leave students feeling like they're wrapped in wet towels. The built-in antibacterial treatment stops odor-causing bacteria for multiple sessions between washes—a practical detail serious practitioners notice right away.

Their diamond-shaped crotch panel design fixes a common yoga wear failure point. Standard construction creates stress at seams during hip openers and splits. This engineered panel spreads tension across the fabric. It stops the early wear patterns that ruin cheaper leggings.

Printing Precision for Brand Identity

Berunclothes offers sublimation printing that differs from traditional screen printing. The numbers tell the story:

Durability comparison: Sublimation graphics survive 50+ wash cycles without fading. Traditional prints start breaking down around wash 10-20. Customers who invest in premium yoga wear expect it to last.

Coverage capability: Sublimation allows full-surface, edge-to-edge designs. Traditional methods limit you to small print areas. Want gradient patterns across entire leggings? All-over tribal prints? Complex geometric designs? Sublimation makes it possible.

Breathability preservation: Sublimation maintains 100% fabric breathability. The dye bonds at molecular level. Traditional prints create a plastic layer that blocks pores and traps heat—bad news for hot yoga.

Their Pantone color system maintains ΔE < 2 color tolerance . This ensures your signature purple stays the same across production batches. One client ordered yoga leggings in 8 custom colorways. Every batch matched spot-on. Consistency like this builds brand recognition.

Quality Control That Prevents Expensive Mistakes

Their 4-step QC system uses AQL 2.5 inspection standards —the same strict protocol high-end athletic brands demand. But the real difference shows up in their cutting precision.

Industry problem: Manual cutting creates ±10+ cm variance in pattern pieces. Solution: Berunclothes uses German CAD auto-nesting combined with laser-guided cutting to achieve ±2-3 cm cutting tolerance . They verify every measurement through digital systems. This precision means your size Small fits the same way across thousands of units.

Seam integrity gets close attention. Japanese Juki and Brother industrial machines handle the sewing. Then comes 100% seam inspection checking for loose threads, uneven stitch density, and puckering. Mid-production inspections catch problems before they spread. Final inspection reports document detailed measurements before shipment.

Their zero-tolerance quality policy showed up strong during one client's batch with defects. Berunclothes scrapped the entire production run and remade it. Met the original shipment deadline. Absorbed the cost themselves. This is how they protect their reputation.

Production Process Transparency

Step 1: Inquiry response within 1 hour during business hours. Submit your style requirements, fabric preferences, quantity, and timeline. Their team checks if it's doable right away.

Step 2: Design confirmation with CAD technical drawings for your approval. They ship physical fabric swatches so you can test texture and performance before committing. No guessing about how your final product feels.

Step 3: Detailed pricing breakdown arrives within 24 hours. Clear cost structure. Volume discount tiers explained. No hidden fees pop up later.

This manufacturer works well for yoga brands seeking OEM/ODM partnerships for Yoga Apparel with real design control. Studio launching a signature collection? Established activewear brand expanding your line? Berunclothes scales with your growth.

Their 30-year manufacturing foundation plus low minimums creates a rare advantage: enterprise-level quality systems that emerging brands can access. You get the fabric technology and construction precision that built their reputation—starting with just 50 pieces.

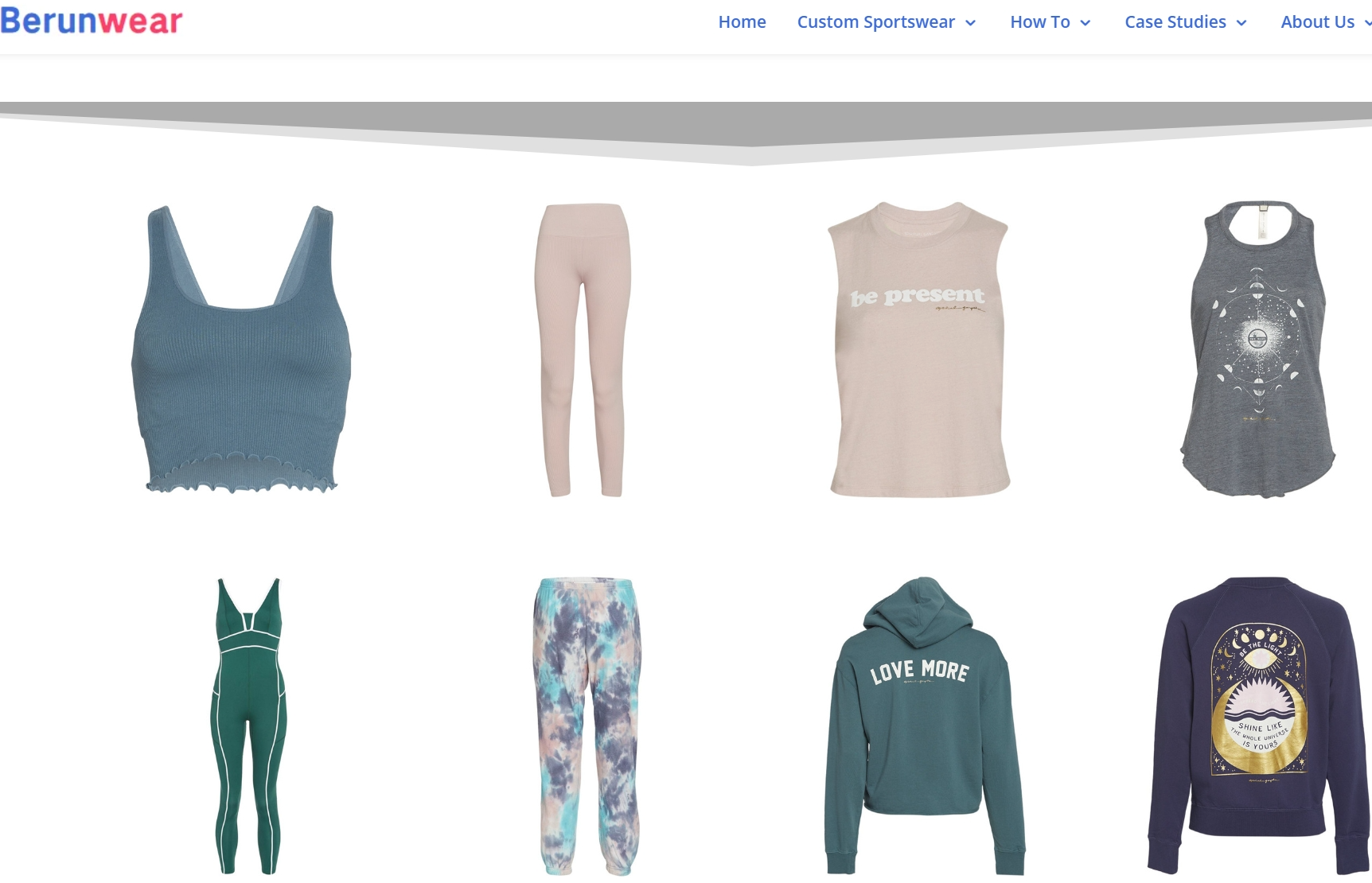

2.Berunwear: Best for Sustainable and Eco-Friendly Yoga Apparel

Sustainability isn't optional anymore. Your customers expect it before they click "buy." Berunwear is a custom yoga wear manufacturer built for brands launching eco-conscious collections. You get no compromises.

The market shift happened fast. Arrivals labeled "recycled" jumped 642% for men and 388% for women in U.S. athletic apparel year-over-year. The yoga clothing category alone grew 144% in the same timeframe. That's six times faster than the overall 26% growth in women's athletic wear. Every major buyer now requests at least one sustainable option per collection. Berunwear sits right at the center of this demand.

Sustainable Fabric Arsenal That Performs

Recycled polyester from post-consumer plastic bottles forms their core eco offering. This isn't greenwashing. Each yoga legging diverts real plastic waste from landfills. You get the same four-way stretch and moisture-wicking performance as traditional polyester. Premium and direct-to-consumer brands prefer this for its durability story. Customers love knowing their workout gear came from recycled materials.

Organic cotton options answer the natural fiber preference. Grown without harmful pesticides and using less water than conventional cotton. This creates softer-on-skin yoga tops and relaxed-fit pieces. Mass-market and specialty brands both request this. They want its gentle feel and lower chemical footprint.

Bamboo and modal blends offer that silky handfeel serious yogis notice right away. The renewable sourcing makes for strong brand storytelling. TENCEL™ lyocell rounds out their high-end sustainable fiber selection. It's biodegradable, moisture-wicking, and smooth enough for luxury yoga collections.

Beyond Fabric: Complete Sustainable Manufacturing

Berunwear supports minimalist, plastic-free packaging and biodegradable packaging alternatives . Brands serious about reducing environmental impact appreciate these options. No need to source them on your own.

QR codes on garment labels enable supply-chain transparency stories. Customers scan and learn where their yoga pants came from. Eco-conscious consumers look for this feature. Some clients even run take-back programs for end-of-life garment recycling. Berunwear's systems accommodate this.

This manufacturer suits brands entering the sustainable athleisure market . The market was valued at USD 90.62 billion in 2022 . It's projected to reach USD 134.67 billion by 2031 . Their OEM/ODM capabilities handle everything. Fabric selection, custom colors, prints, and ethical manufacturing documentation. Your customers want these things more than ever.

3. Ohsurewear: Best for Startups & Fast Private Label Launch

Ohsurewear runs lean and fast—what startups need for their first yoga collection. Over a decade in activewear taught them one truth: new brands can't wait months or gamble on huge minimums.

Speed and accessibility drive everything they do. 100 pieces per style/color gets you started. That's half what most Chinese makers require. Launch your signature black legging plus a burgundy version. No need to blow your entire budget upfront.

The Timeline Advantage for Market Testing

Sample turnaround runs 7-14 days. Submit your design specs Monday. Physical samples arrive before month's end. Test the fit on real bodies. Check if that waistband sits right during sun salutations. Confirm your sizing before production starts.

Bulk production clocks 15-30 days for standard orders. Complex customizations might push to 45 days max. Compare this to the industry norm of 60-90 days. Racing to catch activewear trends or seasonal buying windows? Those saved weeks make a difference.

One fitness influencer used this speed to launch during peak New Year resolution season. Samples arrived mid-November. Bulk order shipped before Christmas. First Instagram drop went live January 2nd. Sold out in three weeks.

Full-Package Service from Concept to Carton

Ohsurewear handles the complete OEM/ODM journey . No tech pack experience? Their design team turns your Pinterest board into production-ready specs. Already have patterns? They tune them for better manufacturing.

Digital printing capabilities unlock creative freedom. All-over mandala patterns. Gradient color shifts. Photorealistic nature scenes across leggings. Traditional screen printing can't match this detail level. The sublimation process keeps fabric breathable. Graphics stay sharp through dozens of washes.

Seamless construction removes the annoying side seams that rub wrong during warrior poses. Their Italian-imported circular knitting machines create tube construction. Less chafing. Cleaner look. Premium feel that customers spot right away.

Strategic Fabric Selection for Brand Positioning

Moisture-wicking synthetics build the performance base. Sweat moves away from skin in seconds. Critical for hot yoga or high-intensity vinyasa classes.

Recycled polyester options answer the sustainability questions before customers ask. Same technical performance as virgin poly. Better brand story. Appeals to the eco-conscious yoga crowd—which now overlaps with most of your customer base.

Four-way stretch with compression creates that locked-in feeling serious athletes want. Fabric recovery stays strong through repeated movements. Your leggings won't bag out at the knees after an hour of practice.

Brand Identity Beyond the Garment

Custom logo printing goes beyond basic screen prints. Embroidery. Heat transfer. Silicone badges. Woven labels. Match the method to your brand positioning.

Branded packaging and hangtags complete the unboxing experience. Polybags with your logo. Thank-you cards. Care instruction inserts. These details separate real brands from obvious dropship operations.

Ohsurewear's production tracking system keeps you informed. Know when fabric arrives. When cutting starts. When your order ships. No more anxious emails about your launch deadline.

The Startup Launch Strategy That Works

Start focused. Two or three hero products beat a scattered 15-piece collection. High-waisted leggings in black, navy, and one signature color. Sports bra to match. Maybe a cropped tank. Test this core lineup first.

Order samples in multiple sizes. Send them to beta testers with different body types. A size small that fits your 5'4" friend might run different on someone 5'9". Fix sizing issues before making 500 units.

Plan your reorder timeline. First batch sells faster than expected? Ohsurewear's quick turnaround lets you restock in under a month. Slow movers? Pivot to new colors without huge financial risk.

Direct-to-consumer brands benefit most from this flexibility. Test Facebook ad creative with real product shots. Scale ad spend once you confirm conversion rates. Reorder inventory based on actual demand data—not guesses.

Lifestyle and wellness companies use Ohsurewear to launch athleisure lines. No need to build in-house manufacturing know-how. Gyms and fitness studios create their own branded merchandise. No need to negotiate with multiple vendors.

The 100-piece minimum means real risk management. Validate your market. Prove your designs sell. Build customer feedback into version two. Scale up production as revenue grows. This is how smart brands launch—test lean before going heavy.

4. Hucai Sportswear: Best for High-Volume Orders with Certified Quality

Dongguan Humen Hucai Garment Co., Ltd operates at a different scale. They pump out 300,000+ pieces per month . That comes from 25 years of production experience. This isn't a small workshop tweaking samples. You get industrial-grade capacity with certified quality standards.

Established brands pick Hucai for one reason: repeatability at volume . Order 5,000 leggings in March. Reorder 10,000 in June. The fabric feels the same. The fit stays consistent. The seam construction matches each time. Your retail partners expect the same product every season. This production stability delivers that.

Certified Systems That Scale Without Breaking

ISO9001 quality management certification means real processes, not just a wall plaque. Every production stage has documented steps. Fabric buying follows written standards. Manufacturing gets tracked with digital systems. Quality checks use the same criteria each time. Packaging and shipping run through verified steps.

BSCI certification proves the factory passed independent social audits. Major retailers and premium brands require this before contracts. It shows safe working conditions. Fair labor practices. Ethical operations. Your due diligence checklist just got shorter.

The OEKO-TEX and Disney FAMA credentials show fabric safety and chemical control. Harmful substances stay out of finished garments. This matters for yoga wear that sits against skin during sweaty 90-minute sessions.

Production Speed Meets Manufacturing Precision

Prototype sampling takes 12-15 days . Time varies based on fabric complexity and printing methods. Their in-house pattern team handles grading and fit adjustments. No outsourcing delays. Submit your tech pack. Physical samples arrive in under two weeks. Make revisions. Approve for bulk production.

Bulk orders ship in 25-35 days after sample approval. The timeline shifts based on fabric sourcing and construction needs. But it stays predictable. Their MES digital production system tracks every order through the factory floor. You see when cutting starts. You see when sewing begins. You see when quality inspection happens. No guessing about delivery windows.

Volume Flexibility With Quality Guardrails

MOQ starts at 100-300 pieces per style . That's accessible for a high-capacity manufacturer. Test new colorways without ordering 5,000 units. Validate seasonal designs before scaling up. Then tap into their capacity for your bestsellers.

One activewear brand started with 200-piece test runs across three legging styles. Sales data showed the high-waisted black legging outsold everything 4:1. They jumped to 3,000 units the next quarter. Hucai's systems handled it. No quality drift. No extended lead times.

Technical Capabilities for Performance Fabrics

Their 4-needle-6-thread construction creates stretch seams for athletic wear. Regular 3-thread construction breaks under repeated stress. Four-needle techniques spread tension across more stitch lines. Seams survive hundreds of yoga flows and wash cycles.

Recycled nylon/spandex blends come standard in their fabric library. Compression fits. Seamless knitting. Bonding and laser perforation for ventilation zones. They handle the technical specs premium yoga brands need.

Internal fabric testing checks shrinkage rates, colorfastness, and stretch recovery before production starts. Problem fabrics get caught early. You won't discover issues after making 2,000 leggings.

The Mid-to-High-End Positioning Strategy

Hucai targets mid-to-high-end sports and yoga clothing . They don't compete on rock-bottom pricing. Their value sits in superior craftsmanship, durability, and product lifecycle . Garments last longer. Construction quality beats fast-fashion standards. Premium yoga brands build customer loyalty through products that last. This approach fits that model.

Their standardized production process gets optimized based on production data. Every batch teaches them something. Process improvements stack up over 25 years. The result? A manufacturing partner that works as a co-developer , not just a cut-and-sew vendor.

This manufacturer fits established yoga brands running stable reorder programs . Your seasonal collections need consistent quality across thousands of units. Your retail partners demand on-time delivery and traceable compliance. Hucai's certified systems and high-volume capacity turn these requirements into routine operations, not risks.

5. Modaknits Apparel: Best for Sustainable & Premium Eco-Friendly Brands

Twenty-six years in the garment business teaches you what matters. Modaknits Apparel learned that sustainability without profitability dies fast. They built both into the same system.

Their factory floor tells a different story than most Asian manufacturers. Fair wages come standard, not as marketing copy. Gender equity programs put women in management roles. This is unusual in traditional textile hubs. The green packaging arrives biodegradable and minimal. Excess waste cuts into margins anyway.

Manufacturing Intelligence That Saves Money and Materials

Modaknits runs digital pattern-making systems that slash fabric waste by 5-10% per production run. One yoga brand client switched from manual cutting to their digital process. Result? 8% reduction in fabric costs across a 2,000-piece order. Those savings add up fast with repeat orders.

Their lean production model speeds delivery by 30% . It also drops inventory holding costs. Smaller buffer stock. Faster turns. Less capital tied up in warehouses. The 100% quality control protocol catches defects before shipping. Fewer returns mean fewer replacement orders eating into your profits.

This isn't feel-good environmentalism. It's operational efficiency dressed as sustainability.

The Fabric Library That Builds Brand Stories

Organic cotton eliminates pesticide concerns. This matters for yoga tops pressed against skin during hot classes. Hemp fabric needs minimal water. It grows fast and absorbs CO₂ while maturing. The durability outlasts conventional cotton by seasons.

TENCEL™ lyocell runs through a closed-loop wood pulp process. The solvents get recycled, not dumped. Your customers care about this. They read garment tags. Recycled polyester diverts plastic bottles and old garments from the 92 million tons of textile waste hitting landfills each year. Modaknits turns production scraps into new fabric bases rather than trashing them.

Transparency Systems Your Buyers Demand

Blockchain chain tracking integrates with platforms like Provenance and CircularID digital tags . Scan a QR code. See where the fabric came from. Track the factory conditions. Check the environmental certifications. Premium brands need this documentation before retail partnerships happen.

Local production cuts transport emissions. It supports regional economies too. Less shipping equals lower carbon footprint and faster sample iterations.

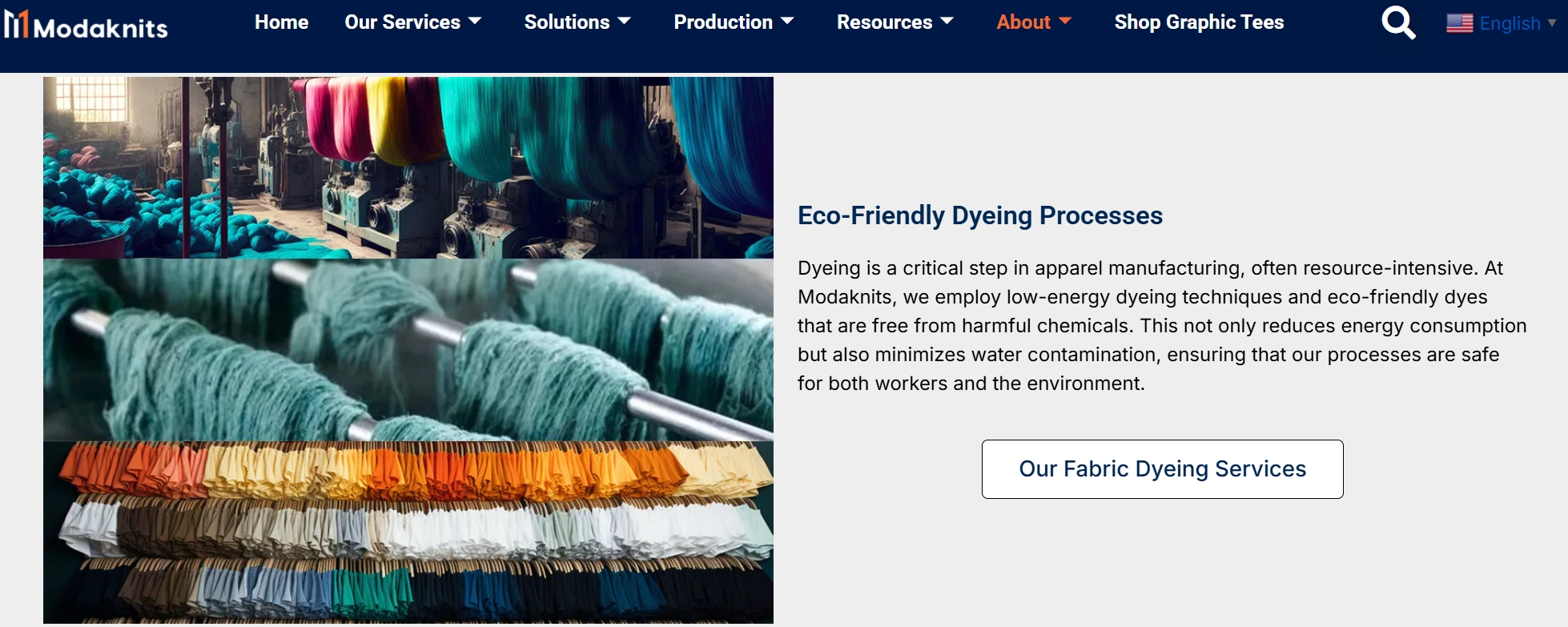

The numbers matter here: 20% of global wastewater comes from textile dyeing and finishing. Modaknits upgraded their water treatment systems to close that loop. Cleaned water gets reused. Chemical discharge drops to near zero.

The Track Record That Backs Claims

1,000+ brands across 28 countries tested their systems. Athletic companies. Yoga studios. Direct-to-consumer wellness brands. They've solved your problem before—likely dozens of times.

Community initiatives include sponsoring local sports tournaments, eco-runs, and sports education programs for girls . These aren't vanity projects. They build goodwill in manufacturing regions. They create stable workforces.

Modaknits works for premium eco-conscious yoga brands . These brands need sustainability credentials verified by third parties. Not just claimed in marketing materials. Your customers ask hard questions about environmental impact. This manufacturer provides documentation that answers them.

6. Fabrics Trades: Best for Mixed Product Types (Seamless + Cut-and-Sew)

Fabrics Trades solves a problem most manufacturers won't touch: combining seamless technology with traditional cut-and-sew in the same production run . Most factories pick a lane and stay there. Seamless specialists refuse cut work. Traditional sewers don't invest in circular knitting machines. This Chinese manufacturer runs both lines under one roof.

The hybrid approach unlocks design freedom your competitors can't match. Seamless body-fitting leggings paired with woven pocket panels . Sports bras with compression zones plus cut-and-sew straps and closures. Activewear sets that blend tubular construction with structured outerwear details. These combinations need two different production systems working in sync.

The Technology Behind Mixed Production

Fabrics Trades operates V-bed flat knitting machines and Santoni circular knitters for seamless work. These Italian-made systems produce garments from yarn to near-finished form. Minimal handling required. Their cut-and-sew department runs traditional spreading, cutting, and sewing operations for woven components.

The coordination challenge? Dimensional control. Seamless fabrics shrink 10-15% during heat-setting . This happens as shrinkable yarns shape compression zones. Cut-and-sew panels must account for this movement. One sizing mistake ruins an entire batch. Think about attaching woven waistbands to seamless legging bodies—precision matters.

Their Santoni DSCS (Digital Stitch Control System) solves this through real-time precision. The technology monitors yarn consumption. It adjusts feed tension each course. Loop length stays under digital control. Result? Fabric dimensional tolerance within 1% across production. This consistency lets seamless panels join cut-and-sew components. No sizing variance kills the fit.

Speed Advantages in Production Planning

Seamless garments take 25-35% less time to manufacture than cut-and-sew pieces. No fabric spreading. No pattern cutting. No hundreds of sewing operations. The machine knits near-complete garments in single runs.

Smart brands use this time difference to their advantage. High-volume basics like solid-color sports bras and leggings run seamless for speed. Complex styles with pockets, zippers, or multi-panel construction get routed to cut-and-sew. One production facility handles both. No vendor juggling or shipment coordination delays.

Zoned Engineering for Performance Design

Zone A uses shrinkable weft yarns to generate peripheral shrinkage. This creates tighter fit areas—think compression panels around the thigh or waist. Zone B employs regular cotton or non-shrinkable synthetics that stay wider. After heat-setting, gathers form in Zone B. Zone A contracts for body-sculpting effects.

Spandex gets placed where stretch and compression matter. Non-elastic yarns handle areas needing drape or breathable width. This zoned approach builds 3D shaping without seams —crucial for yoga wear that moves through constant position changes.

One client designed activewear sets with seamless compression leggings plus cut-and-sew woven shorts overlays. The shorts needed reinforced stitching and pockets. The leggings required 360-degree stretch. Fabrics Trades ran both in parallel. Assembly happened in final stages. The brand got performance bottoms with practical storage—something neither seamless-only nor cut-only factories could deliver.

Product Categories That Benefit Most

Activewear and athleisure programs dominate their mixed production. Seamless creates body-fitting bases. Cut-and-sew adds outer shells, jackets, pocket systems, and trims. You get technical performance where it counts. Plus functional design details customers expect.

Medical and functional compression garments leverage their dual capability. Seamless construction handles tubular supports and compression zones shaped through engineered yarn shrinkage. Cut-and-sew components add fastening systems, adjustable straps, and reinforcing woven panels for joints and closures.

Underwear programs expanding into loungewear run seamless for briefs, boxers, and bras. Then add cut-and-sew nightwear, robes, and woven tops. One supplier handles your entire intimate apparel category. No need to split orders across multiple vendors.

Operational Efficiency for Brands

Pattern measurements for cut components get calculated using post-finishing specs of seamless parts . This accounts for the expected 10-15% shrinkage built into seamless zones. Grading rules align with the ±1% tolerance the DSCS system delivers. Your tech pack process stays unified. Two production methods run in parallel.

Fabrics Trades works best for established yoga and activewear brands launching technical collections . You need seamless performance fabrics for core pieces. You also want design versatility that traditional seamless construction limits. Their hybrid production capability turns complex product development into streamlined manufacturing—all coordinated through one factory partner instead of three.

7. JASAN Group: Best for Ultra-High Volume & Dual-Country Operations

JASAN Group runs at a scale that dwarfs most manufacturers. 500 million pairs of socks per year. 55 million pieces of seamless sportswear. These aren't future goals—they're current output from a company with 10,000 employees across integrated facilities.

Founded in 1994, this Zhejiang-based factory built something rare in Asian manufacturing: complete vertical integration from raw yarn to finished garment . They don't buy yarn from outside suppliers. They produce their own spandex. They operate their own tube dyeing lines. Embroidery? Done in-house. This control removes lead-time issues that destroy multi-country programs.

The Dual-Country Advantage

Global retail chains need backup sources across regions. Tariff changes hit. Shipping stops. Compliance rules shift in one country. None of this halts your production. JASAN's setup lets you source across multiple regulatory systems —US, EU, and more.

Their certifications cover what major retailers require: ISO9001, ISO14000, OHSAS18000 for management systems. OCS, GRS, OEKO-TEX, BCI, WRAP, Better Work for green practices and worker standards. SLCP and Higg Index FEM for environmental tracking. Big retailers check these before signing contracts. JASAN passed the audits already.

Financial Strength for Enterprise Deals

Revenue reached RMB 2.536 billion in the latest twelve months. Operating cash flow runs RMB 505.87 million per year. Free cash flow sits at RMB 273.59 million after capital spending. These numbers show stability. That matters for multi-year, multi-million-piece contracts across continents.

JASAN fits enterprise-level yoga brands and global athletic retailers with programs beyond typical factory capacity. Need hundreds of thousands of seamless sports bras shipped to three continents at once? Their 55-million-piece seamless capacity covers it. Running sock programs for yoga studios across 40+ countries ? Their 500-million-pair hosiery line handles those volumes each day.

Don't test this factory with 500 pieces. Use JASAN as your consolidation partner . Scattered supplier relationships create problems. One strong partner solves them.

8. Guangzhou Yumei: Best for Low MOQ & Multi-Region Export Expertise

Guangzhou Yumei Leather Co., Ltd takes a different path than the mega-factories on this list. They focus on flexibility and global reach —not massive production lines. Their August 2025 export record shows shipments to 31 active buyers across multiple continents . This shows a manufacturer that handles diverse global clients with ease.

Multi-Region Export Credentials That Matter

Trade data confirms Yumei ships to 90+ countries . The United States ranks as a primary destination. Customs records show consistent deliveries to importers like Lash Stuff. But their network goes far beyond North America. European markets show up in their shipping records. So do Asian trading partners and emerging regions.

This geographic spread shows they handle varied compliance standards well. US customs documentation differs from EU requirements. Asian markets have unique labeling rules. African and South American regions bring their own import regulations. Yumei handles all of them on a regular basis. Your brand won't be their first in your target market.

The Small-Scale Advantage

Yumei operates in Guangzhou's cluster of 1-50 employee garment suppliers . This size range usually means lower MOQ thresholds and faster decisions. Compare this to 10,000-employee operations. Those need committee approvals for every production change.

Similar Guangzhou manufacturers in this bracket run 50-300 piece minimums per style . Yumei's profile suggests similar flexibility. Test colorways without committing to thousands of units. Launch limited-edition yoga collections. Validate new designs before scaling production.

Their custom export documentation expertise makes shipping smooth. HS code classification stays accurate. Invoicing matches destination requirements. Shipping paperwork clears customs without delays. These details stop many first-time export programs. Yumei handles them as routine business across dozens of countries each month.

Emerging yoga brands going global benefit most from this setup. You get proven multi-region logistics without massive order volumes. Launch in three countries at once. Yumei's export infrastructure supports it from day one.

Comparison Table: Decision Matrix

Eight manufacturers make choosing hard. This table uses weighted scoring across six key buying factors. Each factor gets a weight based on what buyers care about most: Production Capacity (5) , MOQ Flexibility (4) , Sustainability (3) , Speed-to-Market (4) , Technical Capabilities (3) , and Export Expertise (2) . Scores range from 1-5. A score of 5 means best performance.

Manufacturer | Capacity | MOQ Flex | Sustain | Speed | Tech | Export | Total |

|---|---|---|---|---|---|---|---|

Berunclothes | 3×5=15 | 5×4=20 | 3×3=9 | 5×4=20 | 4×3=12 | 4×2=8 | 84 |

Berunwear | 3×5=15 | 4×4=16 | 5×3=15 | 4×4=16 | 4×3=12 | 4×2=8 | 82 |

Ohsurewear | 2×5=10 | 5×4=20 | 3×3=9 | 5×4=20 | 3×3=9 | 3×2=6 | 74 |

Hucai Sportswear | 5×5=25 | 3×4=12 | 4×3=12 | 4×4=16 | 5×3=15 | 5×2=10 | 90 |

Modaknits | 3×5=15 | 3×4=12 | 5×3=15 | 5×4=20 | 4×3=12 | 5×2=10 | 84 |

Fabrics Trades | 4×5=20 | 3×4=12 | 3×3=9 | 4×4=16 | 5×3=15 | 4×2=8 | 80 |

JASAN Group | 5×5=25 | 1×4=4 | 4×3=12 | 3×4=12 | 5×3=15 | 5×2=10 | 78 |

Guangzhou Yumei | 2×5=10 | 5×4=20 | 2×3=6 | 4×4=16 | 2×3=6 | 5×2=10 | 68 |

Scoring Guide

Production Capacity (Weight: 5) shows how much a factory can produce each month. JASAN and Hucai lead with 500M+ piece output. Berunclothes and Berunwear handle mid-range volumes well. Smaller factories like Guangzhou Yumei score lower here. But they shine in other areas.

MOQ Flexibility (Weight: 4) shows which factories work with startups versus big companies only. Berunclothes, Ohsurewear, and Guangzhou Yumei accept 50-100 piece orders. JASAN needs huge orders. This makes them wrong for market testing.

Sustainability Credentials (Weight: 3) track eco-practices and green fabric options. Berunwear and Modaknits lead here. They offer recycled materials and closed-loop systems. Traditional factories score okay. They meet basic standards.

Speed-to-Market (Weight: 4) covers sample time plus full production time. Berunclothes ships samples in 7-10 days. Ohsurewear keeps the same pace. Bigger factories take longer. They need more coordination.

Technical Capabilities (Weight: 3) rate fabric engineering, seamless tech, and quality control. Hucai has ISO certifications. JASAN runs vertical integration. Both score high. Fabrics Trades wins for mixing seamless with cut-and-sew work.

Export Expertise (Weight: 2) checks shipping experience and paperwork accuracy across regions. JASAN, Modaknits, Hucai, and Guangzhou Yumei ship to 30+ countries often. Factories focused on local markets score lower. Their production quality stays solid though.

Hucai Sportswear's 90 total tops the numbers. High output meets quality certifications and global shipping. But your situation matters more than rankings. Startups launching first products pick Berunclothes ( 84 ) or Ohsurewear ( 74 ) even with lower totals. Low minimums and fast turnaround beat raw capacity for brands testing ideas. Green-focused brands go with Berunwear ( 82 ) or Modaknits ( 84 ). Their sustainability scores make the cost worth it. Big buyers with existing programs use JASAN ( 78 ) for backup across countries. Stiff minimums don't matter to them.

How to Choose the Right Manufacturer for Your Business Stage

Your business stage drives every decision about manufacturer selection. A factory that works great for your competitor could sink your startup. The opposite is also true. Match production partners to where you are now—not where you want to be in three years.

Pre-Revenue and Prototype Testing

Speed and flexibility matter most at this stage. Cost per unit takes a back seat to getting physical samples fast. Look for manufacturers accepting 1-100 piece runs . Berunclothes and Ohsurewear both start at 50-100 units. This range lets you test three colors without dropping $15,000 upfront.

Sample turnaround under two weeks keeps your momentum going. Investors want to see real product. Beta testers need to feel how the fabric performs. Berunclothes ships samples in 7-10 days. Ohsurewear takes 7-14 days. High-volume factories make you wait six weeks.

Design changes come fast during this phase. Your waistband doesn't sit right. Your inseam needs tweaking. The fabric feels too heavy during hot yoga. Find manufacturers who handle revisions without hitting you with $2,000 re-tooling fees every time. Small shops built for iteration work best here.

First Sales and Market Entry

You've sold 200 pieces through Instagram. Pre-orders are coming in. You need batch capacity between 100-5,000 units with steady quality. Ohsurewear and Modaknits handle this range well.

Pick manufacturers offering DFM support —design for manufacturing. They catch production problems before cutting fabric. They suggest build changes that make your product last longer. This saves you from costly errors as you jump from 50 samples to 500 units.

Lead times of 4-10 weeks give you speed plus solid quality control. Rush programs under four weeks skip key inspection steps. Delays past ten weeks wreck seasonal launch windows. Check their work instructions and QC plans . Ask how they handle testing as your volume grows.

Growth Stage and Rapid Scaling

You're moving 5,000-100,000+ pieces per year . Unit economics determine if you survive. Aim for 10-30% cost reduction through better processes. Hucai Sportswear and Fabrics Trades shine here with their automation systems.

Check equipment use rates. Factories running above 80% capacity can't handle your growth spurts. Ask about their MES digital tracking systems . Hucai's production monitoring shows progress in real-time. This stops the "your order got delayed" surprises that wreck retail commitments.

Get their 12-24 month capacity plans . Can they take you from 10,000 to 50,000 units without quality slipping? Ask for proof of similar customer growth they've managed. Vague promises about "we can scale" mean nothing without backup.

Mature High-Volume Operations

You're shipping 100,000+ units across multiple regions . Total cost of ownership matters more than unit price. JASAN Group's dual-country setup handles tariff risks and chain disruptions. Their on-time delivery rate above 95% keeps retail partners happy.

Defect rates below 500 PPM are required. Mass-market yoga brands can't handle high return rates. Check their ISO certifications and ESG compliance. Major retailers audit these before they approve vendors.

Using two manufacturers protects you from single failures. One factory catches fire. Another hits labor strikes. Your production keeps running somewhere else. JASAN's multi-site setup plus a backup tie with Hucai builds this safety net.

Conclusion

Finding the right yoga apparel manufacturer in Asia goes beyond the lowest price. You need a partner who gets your vision and grows with your business. Berunclothes excels in custom design and sustainable yoga apparel production. JASAN Group offers industrial-scale capacity. Each manufacturer on this list has unique strengths.

Match their capabilities with your business stage. Startups do well with low-MOQ partners like Guangzhou Yumei. Established brands can use Hucai's volume efficiency or Modaknits' premium eco-credentials.

Your next step? Don't go at this alone. Reach out to Berunclothes today for a consultation. We've built relationships with Asia's top OEM yoga wear factories. Our team can guide you to manufacturers that fit your budget, timeline, and quality needs.

Need four-way stretch yoga leggings for a boutique launch? Looking for bulk yoga apparel orders for retail distribution? We'll connect you with verified partners who deliver. Your brand concept becomes tangible, market-ready performance yoga fabric technology. Let's build something great together.