You've stood in the activewear aisle, confused. You've sweated through your shirt during HIIT. You've dealt with that post-workout smell. We all have.

"Moisture-wicking" sportswear sounds great. But figuring out what works (versus marketing talk) gets confusing fast.

Here's what matters: breathable athletic fabrics vary widely in quality. Know the science behind sweat absorption. This helps you buy smarter.

Comparing synthetic versus natural fibers? Wondering if high-tech polyester gear is worth the cost? This guide shows you what to look for. Check fabric labels. Examine how it's made.

You'll find performance activewear that keeps you dry and comfortable. No matter if you're doing burpees, sprints, or sun salutations.

Think of this as your shortcut. Get gym clothes that match your effort.

Understanding Moisture-Wicking Technology: How It Works

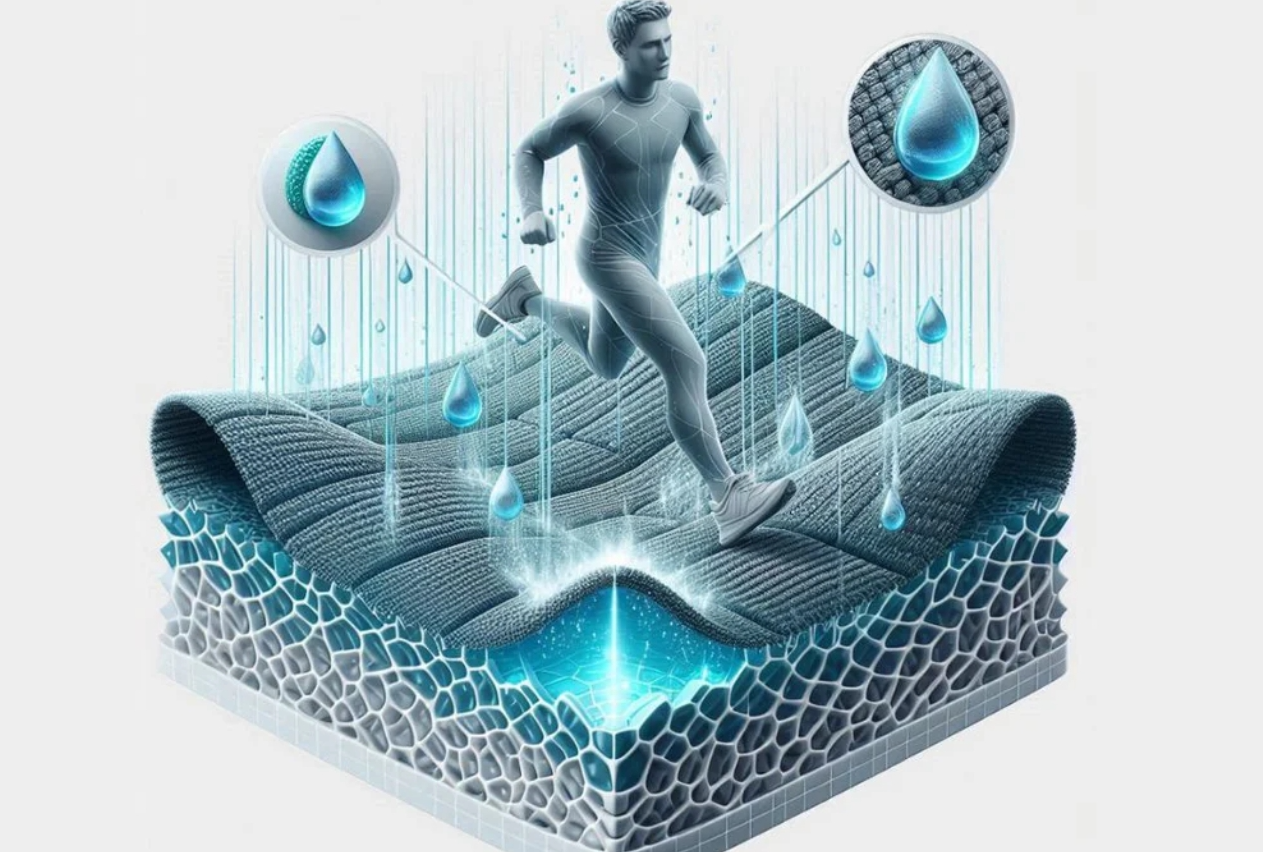

Moisture-wicking fabric acts like a pump system built into your clothes. This happens through capillary action —the same principle that draws water up a paper towel or helps plants move nutrients from roots to leaves.

Here's the simple version: Your sportswear has thousands of tiny fibers woven together. Microscopic gaps between these fibers act as mini channels. Sweat touches the fabric. These channels pull moisture away from your skin using two forces: adhesion (water sticking to fiber surfaces) and cohesion (water molecules attracting each other).

Your sweat takes a three-stage journey:

Stage 1: Wetting

Sweat hits the inner fabric layer. Is the fiber surface water-friendly (hydrophilic)? Moisture spreads across it fast. Is it water-repellent? The process stops right there.

Stage 2: Transport

The fiber channels spread moisture across and through the fabric. Tighter yarn twists create smaller gaps. These gaps have stronger pulling power. They move sweat farther. Looser twists handle more sweat but over shorter distances.

Stage 3: Evaporation

Moisture reaches the outer fabric surface. Air exposure turns it into vapor. This step needs to happen as fast as transport. Otherwise? The fabric gets waterlogged and feels clammy.

The Hydrophobic-Hydrophilic Partnership

Top performance activewear uses smart fiber combinations. Hydrophobic fibers (like untreated polyester) repel water. They push it outward. Hydrophilic fibers grab and channel moisture through their structure.

The best designs layer these properties. Inner surfaces are a bit water-attracting to pull sweat off skin. Outer surfaces repel water to spread and release it fast. This creates a wetting gradient —a one-way moisture highway from your body outward.

Some fabrics use dual-gradient construction . Inner layers have large, water-loving pores that absorb fast. Outer layers have tiny, water-resistant pores that disperse and dry quick. The result? Sweat gets "pumped" away from your skin on its own.

Why Structure Beats Material Alone

Two shirts made from the same polyester can work very different. Here's why:

Pore size : Smaller channels create stronger capillary pressure. They move moisture farther. Larger channels handle heavier sweat output.

Fabric density : Tight weaves form continuous moisture pathways. But too much thickness slows drying.

Chemical treatments : Manufacturers can make water-repellent polyester behave like a sponge through surface changes. Or they coat cotton to stop it from holding water.

Cotton absorbs sweat well—but then traps it inside the fiber. You stay wet. Modern synthetic moisture management flips this. Minimal absorption. Maximum surface spreading. Rapid evaporation.

The best gym clothes moisture control combines engineering and fabric science. You're not buying material. You're investing in a climate system designed around how your body sweats.

Step 1: Check Fabric Composition Labels - What to Look For

The fabric label tells you everything—if you know how to read it. Those percentages aren't just legal requirements. They're your performance roadmap.

Look for the fiber breakdown first. Labels must list components by weight, in descending order . A tag reading "65% polyester, 30% nylon, 5% spandex" shows polyester drives the fabric's behavior. The top two ingredients account for 80–90% of the total. They control how your shirt handles sweat.

Pay attention to anything below 5%. Manufacturers sometimes group minor fibers as "other fibers." Hidden ingredients like acrylic or trace wool can trigger skin reactions or change care needs.

Best Fiber Compositions for Sweat Management

Each activity needs its own blend. Here's what works:

For high-intensity workouts (HIIT, running, cycling):

- 80–100% polyester delivers fastest moisture transport

- Mixed blends work fine with polyester at ≥60–70% of the total

- Quick dry sportswear in this range spreads sweat across fabric surface fast

For durability and abrasion resistance (CrossFit, outdoor training):

- 50–100% nylon appears in performance activewear pants and outer layers

- Common power combo: 60% nylon / 40% polyester balances strength with drying speed

- Higher nylon percentage means better hand feel and toughness

For maximum sweat repellency (base layers, hot climate training):

- ≥50% polypropylene creates a water-resistant barrier closest to skin

- Often mixed with polyester or elastane at 40–50% PP minimum

- This synthetic fiber pushes moisture away faster than any alternative

For anti-odor workout gear with heat control :

- 100% merino wool (17–21 micron) for pure natural performance

- 80–90% merino + 10–20% nylon adds durability without losing odor control

- ≥80% merino + 3–10% elastane gives stretch while keeping wool's benefits

The Stretch Factor: Understanding Spandex Percentages

Elastane appears under different names—spandex, Lycra—but the percentage matters more than the label. Getting this ratio right is key for compression wear moisture wicking.

2–4% spandex : Minimal stretch

- Found in casual athletic-inspired clothing

- Examples: "98% cotton / 2% elastane" or "96% polyester / 4% elastane"

- Gives you comfort, not performance flex

- Skip these for serious training

4–8% spandex : The practical sweet spot

- Standard for fitted gym clothes moisture control

- 4–6% : Moderate elasticity for general fitness

- 6–8% : Higher recovery power for dynamic movement

- Works for yoga, strength training, moderate cardio

8–15% spandex : Competition-grade compression

- Common formulas: "75% nylon / 25% elastane" or "80% polyester / 20% elastane"

- Strong hold, maximum support

- Built for sprinting, competitive lifting, or moves that need muscle support

Quick decision rule : Under 4% won't give you athletic flex. Between 4–8% handles most workout demands. Above 8% means serious compression performance.

Shop smart—photograph promising labels. Compare percentages across brands at home. The winning formula? High synthetic content (≥60%) for breathable athletic fabric plus moderate stretch (4–8%) for movement freedom . That balance keeps you dry, supported, and comfortable through every rep.

Step 2: Decode Moisture-Management Technology Terms

Marketing labels toss around terms like confetti. "Moisture-wicking." "Quick-dry." "Stay-dry technology." They sound impressive. But most brands define these words however they want.

The textile industry has no universal rulebook for these claims. One company's "moisture-wicking" might mean real lab-tested performance. Another's? Just polyester doing what polyester does (which isn't much without proper design).

Here's what matters:

Real Wicking vs. Marketing Fluff

True moisture-wicking fabric moves liquid water away from your skin through designed capillary action. The gold standard? AATCC Test Method 195—the one recognized lab protocol that measures this with data.

Look for garments that reference this test. Quality makers will mention it somewhere—hang tags, product pages, or spec sheets. The magic number you want: AOTI (Accumulative One-Way Transport Index) above 0.3 . Better brands hit 0.4 or higher.

Nike's Dri-FIT scores around 0.45. Adidas ClimaLite and similar premium tech land between 0.35–0.50. Anything below 0.2? That's basic synthetic fabric pretending to be high-performance.

Quick visual test : Wet your palm. Press it against the fabric for 10 seconds. Real moisture management tech will spread that wetness across a 5+ cm radius within 60 seconds. The spot should feel almost dry when you touch it again. Standard polyester just creates a damp handprint that sits there.

The Three Terms That Mean Something

"Moisture-wicking" requires specific fiber content—most often 85% or more polyester, polypropylene, or treated hydrophilic synthetics. Cotton blends below 50% synthetic content can't deliver true wicking action. The label promises don't matter.

"Quick-dry" means evaporation completes in under 30 minutes after absorption. Cotton takes two hours. This isn't just about convenience. Trapped moisture leads to chafing, temperature drops, and bacterial growth. Premium quick-dry sportswear uses micro-denier fibers (under 1 denier per filament). These often include mesh ventilation panels that boost evaporation rates by 25%.

"Stay-dry" means the bottom fabric layer (against your skin) holds less than 20% moisture retention. The top surface disperses sweat. The technical measurement: TAR/BAR ratio above 1.5. This means the outer surface absorbs much more than the inner. Your skin stays dry. Moisture escapes outward.

Brand Technology Translation Guide

Premium activewear brands build custom systems around these principles:

Nike Dri-FIT uses grooved polyester microfibers (85–95% composition). These wick 3–5 times faster than cotton. They dry 40% quicker than standard polyester. Their fiber surfaces have microscopic channels that speed up capillary pull.

Adidas ClimaLite combines 90% polyester with placed mesh zones. The open construction allows airflow. This evaporates sweat 20% faster than solid-weave alternatives. Their wetted radius exceeds 12mm—strong lateral spreading.

CoolMax technology features four-channel polyester fibers. These create extra surface area. Those channels pull moisture 50% faster than flat polyester. They transport it 70% better than cotton. Bottom surface wetting time: under 3 seconds.

Your Label Authentication Checklist

Separate real thermal regulation clothing from empty promises:

Fiber percentage reality check : Anything claiming moisture management should show 85%+ polyester, nylon, or polypropylene. Cotton-heavy blends (even 50/50 splits) won't perform. Marketing language doesn't change this.

Certification proof : Look for AATCC 195 test results, Oeko-Tex Standard 100 marks, or specific AOTI scores. Generic "moisture-wicking" or "breathable" without supporting data? That's a red flag.

Construction clues : Examine the weave. Micro-denier yarns feel super smooth. Grooved or channeled fibers show visible texture under good light. Mesh panels aren't decorative—they're functional evaporation zones.

What screams "marketing hype" : 100% cotton or merino labeled as "moisture-wicking" (they absorb, not transport). "Breathable" used alone without wicking claims (all fabric breathes to some degree). No mention of testing standards or performance metrics anywhere.

Good manufacturers like specialized activewear producers test everything. They'll reference AATCC 195 protocols, ISO 6330 drying rates, or ASTM D737 air permeability standards (you want above 100 CFM per square foot). Industry benchmarks demand bottom wetted radius exceeding top surface by 20%+ and overall moisture management capacity above 800mg.

The takeaway : Don't trust adjectives. Trust testing standards, fiber percentages, and brands transparent enough to share real performance data. Your skin will thank you.

Step 3: Check Breathability and Fabric Weight for Your Climate

Climate matters most for workout gear. A shirt that works for Boston winter training? It'll drench you in Miami summers.

Fabric weight uses GSM (grams per square meter). This number shows fabric thickness and how it handles temperature changes.

Match GSM to Your Environment

Lightweight fabrics (100-150 GSM) suit hot, humid conditions above 25°C. Summer running. Outdoor CrossFit. Beach volleyball. These thin fabrics focus on air flow, not warmth. Sweat evaporates fast instead of soaking the fabric.

Midweight fabrics (150-250 GSM) work for 10-25°C climates. Spring runs. Fall hikes. Indoor gym sessions with mixed air conditioning. This weight gives you moisture control plus light warmth. You stay cool during warm-ups. You stay warm during cool-downs.

Cold weather needs a different choice. Get merino wool blends at 200-250 GSM . Look for 50-70% merino mixed with synthetics. These pull moisture 30% faster than cotton. They also hold 20-25% more body heat at 0-10°C. Pure synthetics can't match wool's warmth without trapping sweat.

Breathability Metrics That Matter

MVTR (Moisture Vapor Transmission Rate) shows how much sweat vapor passes through fabric in 24 hours. Higher numbers equal better breathability.

Hot climates above 25°C need MVTR above 15,000 g/m²/24h . Gore-Tex Paclite hits 15,000. That's a good target for intense heat workouts. Premium shells reach 25,000 (like Gore-Tex Pro). You'll pay more though.

Cold or mild weather training uses 9,000-17,000 g/m²/24h . This stops moisture buildup. It keeps warmth too. Below 9,000? Your base layer traps sweat.

RET (Resistance to Evaporative Heat Transfer) works opposite. Lower scores mean better breathability. Get RET under 6 for extreme heat. This counts as "highly breathable" by pro standards. Moderate activity in cooler temps? RET between 6-13 works fine.

Most high-performance gear sits at 10,000-15,000 MVTR. RET stays near 6-9. Budget options top out at 8,000 MVTR. Their RET stays above 13.

Mesh Panel Placement

Ventilation panels serve a purpose. Makers put mesh where your body sweats most. This boosts airflow.

Underarms create up to 20% of body sweat during exercise. Mesh here releases moisture fast. Top brands like Berunclothes use laser-cut holes or special knit patterns in these spots.

Upper back and shoulders trap heat from body movement. Mesh strips across shoulder blades push warm air away from your core. This speeds evaporation by 15-20% compared to solid fabric.

Chest and side panels control core temperature during hard effort. Mesh along the ribcage creates cross-flow. Critical for burpees or mountain climbers.

Inseam and groin areas fight friction and moisture. Ventilation here stops chafing. It blocks bacteria in tight spaces.

Zippered vents give you control. Pit zips, back zips, or side panels boost airflow by over 5,000 MVTR on demand. This helps during mixed-intensity workouts or weather shifts.

Quick Climate-Matching Formula

Hot weather (>25°C, high intensity) :

- GSM: Under 150

- MVTR: Above 17,000 g/m²/24h

- RET: Below 6

- Construction: Maximum mesh coverage, pit zips standard

Mild weather (10-25°C, moderate intensity) :

- GSM: 150-250

- MVTR: 10,000-15,000 g/m²/24h

- RET: 6-13

- Construction: Some mesh panels, optional venting

Cold weather (0-10°C, mixed intensity) :

- GSM: 200-250 (merino blend works best)

- MVTR: 10,000-15,000 g/m²/24h (keep breathability, don't trade it for warmth)

- RET: 6-13

- Construction: Less mesh, fiber tech moves moisture

Testing standards count. ASTM E96 B copies real body temperature (35-36°C). JIS L1099 A1 uses lab highs that boost numbers. ISO 11092 measures RET with real heat stress. Good makers list these tests in their specs.

Performance activewear makers like berunclothes share full breathability data. Match these numbers to your training climate. A 120 GSM shirt with 18,000 MVTR beats a 180 GSM option at 9,000 MVTR for summer marathons. Even if the heavier one costs more.

Your climate sets your comfort. Pick fabric weight and breathability that fit your reality. Not what marketing claims.

Step 4: Assess Fit, Cut, and Construction Quality

Perfect fabric means nothing if the cut fights your movement or seams dig into your skin after mile three. Good construction makes gear last. Poor construction? You'll donate it after two washes.

Match Cut to Your Training Style

Different workouts need different fits. Get this wrong and you'll deal with friction, restricted movement, or constant adjusting mid-set.

Running needs slim-fit precision . Your top should measure chest width at body circumference plus 6–10 cm. This gives you room without excess fabric flapping. Pants taper to ankle-hugging cuffs. Leave 6–8% extra through the thighs for stride clearance.

Check the hem difference: front should sit 1.5–3 cm shorter than back. This keeps your lower back covered during forward leans. Raise both arms to 90 degrees. The bottom edge shouldn't ride up more than 5 cm past your waistline. Test your longest stride for 20–30 steps. No pulling at the crotch or side seams? That's proper pattern design.

Yoga requires four-way stretch . Fabric must extend 50–70% in both directions—warp and weft. Pull a sleeve or leg to 1.5 times its resting length. Release. Good compression wear with moisture wicking bounces back to 95% original size within 30 seconds.

High-waist leggings should sit 3–6 cm above your natural waist. The gusset (that diamond panel at the crotch) needs at least 8–10 cm along its longest edge. This spreads out tension during deep hip openers. Run through five sun salutations, five splits, five deep squats. Watch knees and glutes. See white stress lines or see-through fabric? Size up or skip that brand.

HIIT demands graduated compression . Athletic compression follows medical-grade pressure ranges: 10–15 mmHg for recovery, 15–20 mmHg for active training. Put it on. Indentation deeper than 1 mm or numbness within five minutes? Construction is too tight.

Stretch the fabric 30%. Let go. It should snap back in under two seconds without ripples. Do 20 continuous high-knees and burpees. Chest panels and thigh bands shouldn't shift or roll.

Decode Seam Construction

Flatlock seams lie flat against your skin. Four to six parallel thread lines stitch edges together with 3–4 mm spacing between needle punctures. Run your finger across the inside. You'll feel almost nothing. This helps during marathon training or hot yoga—anywhere skin rubs fabric for long periods.

The trade-off? It costs more to make. Stretch zones under extreme tension can pop threads if tension isn't spread evenly across all needle lines.

Seamless construction uses circular knitting. One continuous tube forms the body. Shoulders and inseams are the areas that need joining. High-stress areas like shoulders or crotch have 5–15% denser knit weight (higher GSM) than the torso.

Benefits: minimal friction points, built-in compression mapping through stitch pattern changes. Limitation: less shape control compared to cut-and-sew patterns. A tear can't be repaired—you're replacing the whole piece.

Bonded seams skip thread. Heat-activated adhesive tape (8–12 mm wide) fuses fabric layers. Premium gear uses 10+ mm tape width at stress points. Test peel strength by pinching the seam edge—it shouldn't separate under firm pressure.

Bonded construction creates waterproof joins. Perfect for outer layers. Inside base layers, poor-quality bonding can stiffen and crack after repeated washing. Check care labels. Hand-wash recommendations for bonded synthetic vs natural fibers often mean weaker adhesive.

Your best move? Inspect inside seams under good light before buying. Quality activewear shows consistent stitch density, smooth tape application, or invisible flatlock work. Puckered fabric, skipped stitches, or peeling tape? Walk away no matter what brand name is on the label.

Step 5: Consider Odor Control and Skin Comfort Features

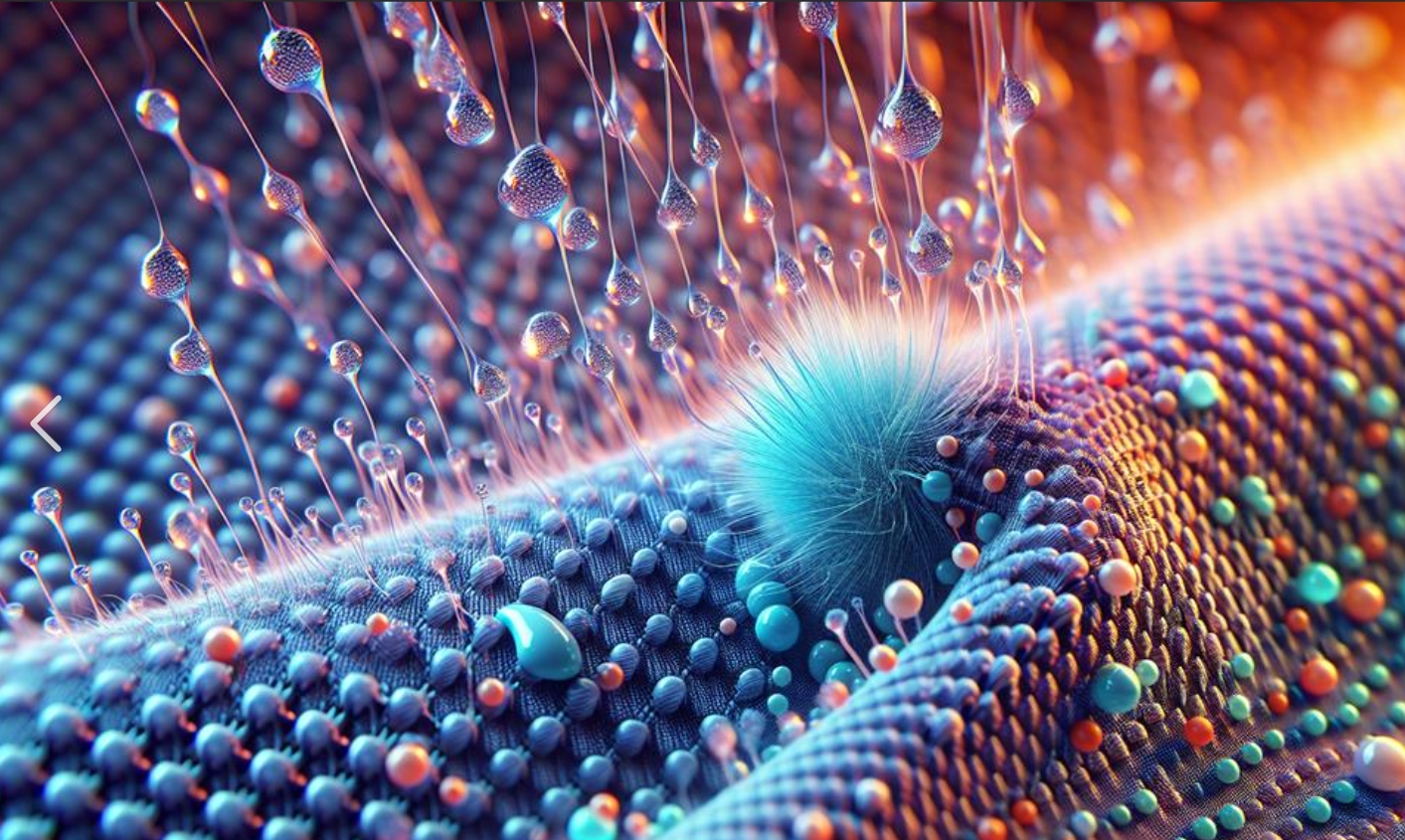

Bacteria feed on sweat and create that post-workout smell. Not the sweat itself. Control the bacteria, you control the odor.

Silver Ion Technology: The 99% Standard

Silver-based antimicrobial treatments lead the anti-odor workout gear market. They disrupt bacterial cell walls. Industry testing uses AATCC 100 and ISO 20743 protocols. The baseline? Above 99% bacteria reduction against common culprits like Staphylococcus aureus and E. coli after 24 hours.

Nano-silver particles measure 10–100 nanometers . This tiny size spreads evenly across fabric. It doesn't change softness or block breathability. Quality makers bond these particles to fiber surfaces through chemical linking. Not just surface coating that washes away fast.

Durability beats starting performance. Premium silver treatments keep above 90% antibacterial power after 50+ washes at 40°C with standard detergent. Mid-range products claim 20–50 wash cycles before you see decline. Budget options? Odor control fades after 15–20 washes. Your gym clothes will smell bad within hours of heavy training once the treatment wears out.

Look for ISO 17299 certification on labels. This standard tests fabric against four major odor compounds—isovaleric acid, ammonia, trimethylamine. Passing grade requires minimum 70% odor reduction compared to untreated fabric. Without this testing proof, "odor-resistant" claims mean nothing.

Natural Fiber Performance: Merino Wool Wins

Merino wool beats synthetics for multi-day odor control without chemical treatments. The secret? Its protein structure resists bacterial growth. Plus merino absorbs over 30% of its weight in moisture vapor while still feeling dry against skin. Less surface moisture means fewer bacterial breeding grounds.

Lab tests show merino fabrics hold 10–100 times fewer bacteria than polyester after the same workout sessions. Smell panels rate merino shirt odor 1–2 grades lower on standard scales versus synthetic options.

Bamboo viscose gets sold as antibacterial by nature. Reality check: most "bamboo fabric" is regenerated cellulose. Any germ-fighting properties come from chemical finishing. Not the bamboo itself. These treatments deliver 70–90% bacteria blocking at first but fade after 20–30 washes . Similar to budget silver applications.

Specialized moisture-wicking sportswear manufacturers like berunclothes often mix merino blends with smart synthetic placement. You get odor resistance where it counts (underarms, back) plus synthetic strength in high-wear zones.

Step 6: Match Sportswear to Specific Activities

Your workout defines what you need to wear. Marathon runners need different gear than powerlifters. Basketball shorts don't work for yoga. Activity-specific design is about physics and body movement, not just marketing.

Running and HIIT: Speed Demands Lightweight Precision

Fabric weight sits at 120–160 GSM for serious runners. This light range gets rid of heat fast during cardio. Your body makes 800–1,200 watts of heat during high-intensity intervals. Heavy fabric holds it in. Light fabric lets it out.

Synthetic blends work best: polyester base with 8–20% spandex hits the sweet spot. Nylon strengthens high-friction zones—inner thighs, underarms. This tri-blend moves sweat, stretches, and lasts.

Fit affects your mind more than you think. Research shows tight-fit running gear looks 10 times more competitive and goal-focused than loose options. Female study participants saw male runners in compression gear as "training for their next race" at much higher rates. This perception boosts your confidence. Your brain sees the compression and thinks "athlete mode."

Pick slim-fit tops and semi-compression shorts or tights . This cuts down fabric movement during your stride. Less movement means less chafing over 10K+ runs.

360-degree reflectivity saves lives. Night running needs visibility from all angles:

- Front chest and shoulder strips catch headlights coming at you

- Upper back placement alerts traffic from behind

- Side seam and outer knee reflectors help with side detection

Quality running tops cover front + back + at least one full side seam with reflective details. Pants add outer leg strips from hip to ankle.

Team Sports: Durability Meets Multi-Directional Stretch

Soccer, basketball, and field sports tear up lightweight gear. Fabric weight goes up to 150–220 GSM —almost double running shirt thickness. This stands up to turf slides, jersey grabs, and equipment friction.

Strong construction focuses on stress points:

- Double or triple-stitched shoulder and side seams fight pulling during contact

- Strong necklines stop collar stretching

- Diamond gusset panels at the crotch with strong stitching prevent tears during side movements

Four-way stretch is a must. Running moves you forward. Team sports need quick starts in any direction. Look for 10–20% elastane content through the whole garment—body, sleeves, and leg panels. Test by pulling fabric at an angle. It should stretch 50% with ease.

Air panels go right where heat builds up:

- Underarm-to-side-waist mesh zones (the biggest sweat area during sprints)

- Flat mesh bands across upper back between shoulder blades

- Inner thigh and crotch holes fight moisture in tight shorts

Top team wear from makers like berunclothes puts these panels based on thermal mapping data. Not for looks. For cooling that works.

Gym and Strength Training: Maximum Mobility Without Restriction

Big movements—squats, deadlifts, overhead presses—need full range-of-motion freedom . Your clothes must feel like nothing during a 200-pound back squat or 90-degree shoulder turn.

Gusset build in pants gives hip room to move. That diamond-shaped panel at the crotch should be at least 10–12 cm along its longest side . This spreads tension during deep squats. Without it? Seams pull. Fabric holds you back. You use bad form to make up for it.

Top needs for strength training gear:

- Raglan or set-in sleeves with underarm gussets for free overhead pressing

- Mid-rise or high-rise waistbands that don't slip during Romanian deadlifts (no skin showing during hip hinge)

- Strong knee panels if you do barbell lunges or floor work

- Flat-seam build on inner thighs —barbell back squats create 40+ friction cycles per set

Fabric feel counts more here than cardio gear. Powerlifters like soft polyester blends (brushed inside finish) over slick tech fabrics. The slight texture grabs barbells better during heavy pulls. It also stops slipping on bench padding.

Match your gear to how hard you train. Get the build right. Your performance limit goes up with it.

Fabric Comparison Table: Pros, Cons, and Best Use Cases

Six fabrics dominate athletic wear. Each one performs based on how you move, where you train, and what matters most—sweat, smell, or price.

| Fabric | Wicking Speed | Drying Time | Odor Control | Durability | Price Range |

|---|---|---|---|---|---|

| Polyester | ★★★★★ (4-5/5) | ★★★★★ (4-5/5) | ★★☆☆☆ (1-2/5) | ★★★★★ (4-5/5) | $10-40 |

| Nylon | ★★★★☆ (3-4/5) | ★★★★☆ (4/5) | ★★☆☆☆ (2/5) | ★★★★★ (5/5) | $40-200 |

| Cotton | ★★☆☆☆ (1-2/5) | ★★☆☆☆ (1-2/5) | ★★★☆☆ (3/5) | ★★★☆☆ (3/5) | $5-30 |

| Merino Wool | ★★★☆☆ (3/5) | ★★★☆☆ (2-3/5) | ★★★★★ (4-5/5) | ★★★☆☆ (2-3/5) | $60-150+ |

| Bamboo Viscose | ★★★☆☆ (3/5) | ★★★☆☆ (2-3/5) | ★★★☆☆ (3/5) | ★★★☆☆ (2-3/5) | $20-70 |

| Elastane/Spandex | ★☆☆☆☆ (1/5) | Varies | ★★☆☆☆ (2/5) | ★★☆☆☆ (2/5) | +$5-15 per item |

Polyester Wins Here

Polyester moves sweat 30-60 seconds after contact. It dries 50-70% faster than cotton . Your shirt feels dry within 20-30 minutes post-workout. No more damp clothes for hours.

Best for : HIIT sessions, running, cycling, hot yoga, any high-sweat cardio in warm climates above 25°C.

The smell problem : Synthetic fibers trap odor-causing bacteria. Sweat tests show polyester scores worst for lingering smell versus natural fibers. The fix? Look for silver-ion treatments or wash right after training.

Nylon's Toughness Trade

Nylon beats every fabric for abrasion resistance. Outer seams last through pavement slides, equipment friction, and repeated wash cycles. It's the go-to for performance activewear pants and jackets .

Moisture management sits a bit behind polyester—call it 3-4 out of 5. Still solid. Still quick-dry sportswear worthy.

Best for : CrossFit, outdoor training, trail running, team sports with contact or ground work.

Price reality : Quality nylon pieces start at $40. Premium shells and pants push $150-200. You're paying for years of wear.

Cotton's Comfort Problem

Cotton absorbs moisture—then holds it against your skin. A damp spot can stay wet for 5+ minutes before spreading. Total drying time? Two to three times longer than synthetics.

Use cotton for : Light stretching, casual gym visits under 30 minutes, yoga in air-conditioned studios where you don't sweat much.

Avoid it for running, HIIT, or anything producing continuous sweat. The wet fabric weight creates chafing and temperature drops.

Merino Wool's Premium Performance

Merino absorbs 30% of its weight in moisture vapor while your skin stays dry. Lab tests show 4-5 times better odor resistance than polyester after the same workouts. You can wear the same merino base layer multiple training sessions before washing.

Best for : Cold-weather running (0-10°C), multi-day hiking, winter sports, any case where you need thermal regulation clothing plus sweat control.

The cost barrier : Quality merino starts at $60 per piece. Premium options exceed $150. Brands like berunclothes offer merino-synthetic blends that cut costs while keeping odor benefits.

Merino doesn't last as long as synthetics. Fine merino fibers (17-21 micron) wear faster than polyester. Expect 2-3 seasons of heavy use versus 4-5 for synthetic options.

Bamboo's Marketing vs Reality

Most "bamboo fabric" is regenerated cellulose viscose. The antibacterial claims? They come from chemical finishing treatments—not the bamboo plant itself. These treatments deliver 70-90% bacteria reduction at first but fade after 20-30 washes.

Moisture absorption sits high. Drying speed lags behind synthetics. Wet-state strength drops.

Best for : Casual activewear, light yoga, anyone seeking green options who accepts performance trade-offs.

Realistic expectations : Treat bamboo viscose like upgraded cotton. Better than pure cotton for gym clothes moisture control. Not as effective as engineered synthetics.

Elastane's Supporting Role

Spandex appears at 5-20% blend ratios . It provides stretch and recovery. Nothing else. The other fibers handle moisture—polyester, nylon, or merino.

4-8% elastane handles most athletic needs. 8-15% elastane delivers competition-grade compression wear moisture wicking . Below 4%? Skip it for serious training.

Elastic fibers fatigue over time. Expect gradual stretch loss after 50-100 wash cycles even with proper care.

Quality Check Methods: In-Store and Online Shopping

Shopping smart means testing before trusting. You're either touching fabric in-store or reading product pages online. Either way, specific checks separate quality gear from pretty marketing.

In-Store: Three Physical Tests That Reveal Everything

The stretch recovery test shows how your gear will perform after 50 washes. Find a hidden spot—side seam, lower hem—and pull the fabric to 130-150% of its resting length . Hold for 3-5 seconds. Release.

Watch what happens in the next 1-2 seconds. Quality moisture-wicking sportswear snaps back right away. No waves. No permanent stretching. The fabric remembers its shape. Budget options stay loose, wrinkled, or take 3+ seconds to recover. That's your cue to keep looking.

Repeat this pull 5-10 times fast. Good elastane content (6-8%) won't quit. Poor blends lose tension by the third stretch.

Light penetration reveals fabric density. Hold the garment 5-10 cm from a bright light source. Store ceiling lamps or your phone flashlight both work. You should see even, fine weave patterns. But not clear skin outlines through the fabric.

Now stretch it 10-20%. Can you now see skin color or undergarment shapes? The GSM is too low. White and light colors need higher density. This prevents see-through disasters during squats.

Seam touch predicts comfort. Run your fingertip along shoulder seams, side seams, crotch gussets, and underarm joins from the inside. Feel hard edges, scratchiness, or bumps? That's friction waiting to happen during your workout.

Pull fabric on both sides of the seam—normal dressing force, not extreme tugging. Quality construction shows no gaps wider than 2mm between stitches. Ideal stitch density for performance activewear runs 3-4 stitches per centimeter . Too loose means popped seams. Too tight creates puckering.

Online Shopping: Decode the Product Description

Can't touch the fabric? Read between the marketing lines.

Fabric composition priorities (ranked best to budget):

- "Cotton 90-95% + Spandex 5-10%" : Comfortable for regular training, natural feel, moderate stretch

- "Nylon/Polyamide + Elastane" : High-rebound compression, best for yoga pants and HIIT tights

- "Polyester + Elastane" with "moisture-wicking" or "quick-dry" : Works for sweat management, synthetic performance

- "100% Polyester" with no tech claims: Basic budget fabric, expect mediocre breathability

Quality signals to hunt for:

- GSM listings of 180-220 for shirts (substantial feel without bulk)

- "Flatlock seam construction" (reduced chafing)

- Specific test standards : AATCC 195, ISO 20743, Oeko-Tex certification

Brands like berunclothes list these specs openly. No hiding behind vague "premium fabric" claims. Missing technical details? That's often a red flag.

Care and Maintenance to Preserve Wicking Performance

Wrong washing destroys your gear's performance faster than heavy training ever will. Research shows washed fabrics achieve higher horizontal and vertical wicking rates than unwashed pieces across all weave types—plain, twill, and satin (t-test p<0.05, 95% confidence level). But you need proper care protocols.

The key? Moisture-wicking isn't permanent. It's a partnership between fiber chemistry and fabric structure. You either protect it or destroy it with every laundry cycle.

The Washing Method That Boosts Performance

Lab testing reveals bleached cotton plain weave beats unbleached versions in both horizontal wicking and moisture transfer after washing. Bleaching opens up fiber pathways. Unbleached cotton maintains better water repellency after washing. This trade-off matters for outer layers.

Temperature matters. Wash quick dry sportswear in cold water (below 30°C). Use gentle cycles. Hot water (above 40°C) breaks down elastane fibers 2-3 times faster. Your compression wear loses recovery power after just 15-20 hot washes. Cold washes? You get 50+ cycles before degradation.

Turn garments inside-out before washing. This protects anti-odor treatments—silver ions or antimicrobial coatings—from direct agitation damage. Abrasion from zippers, Velcro, or drum walls degrades these surface treatments 40% faster than protected washing.

Skip fabric softener. It coats synthetic fibers with waxy residue. This clogs those tiny channels responsible for capillary action. One softener wash can reduce wicking rates by 15-25%. Regular softener use? You've converted breathable athletic fabric into water-resistant material.

Drying Decisions That Extend Lifespan

Air-dry your gear. Hang your gym clothes in well-ventilated areas away from direct sunlight. UV exposure breaks down polyester and nylon over time. This weakens fabric by 10-15% per season of sun drying.

Machine drying? Use low heat settings (below 60°C). High heat shrinks synthetic fibers in different amounts. This distorts the precise weave structure that creates wicking performance. Plain weave construction delivers the highest wicking rates. Fiber spacing changes compromise this.

Never iron performance activewear unless you must. Heat over 110°C melts elastane and fuses polyester fibers together. Those once-separated channels for moisture transport? Sealed shut forever.

Structural Factors You Can't Ignore

Medium yarn size beats heavy yarn in both horizontal and vertical wicking after washing (t-test confirms this). You can't change what manufacturers chose during production. What you can control? Preventing structural breakdown.

Research shows single spun yarns beat plied yarns in horizontal wicking. Texturized yarns beat filament yarns across the board. Premium moisture-wicking sportswear from manufacturers like berunclothes uses these higher-performing yarn constructions. Your care routine preserves that engineering investment.

Fabric density impacts longevity. Higher density increases thickness but can weaken moisture management in coarser fabrics. Aggressive washing or high-heat drying compacts these structures further. Stick to gentle mechanical action.

Testing Your Gear's Wicking Maintenance

Industry standards measure whether your care routine works:

AATCC 197-2013 tests vertical wicking rate (mm/s lengthwise). Quality gear should maintain above 80% of original wicking speed after 20 washes with proper care. Below 70%? Your washing method needs adjustment.

AATCC TM217-2025 uses imaging to grade wicking performance across wider data points. This newer standard gives you a full picture of moisture spread—not just vertical movement.

AATCC 22-2014 measures water repellency. High wicking is your primary goal for base layers and shirts. Outer shells need to balance both. Check if water still beads on jacket surfaces after 10-15 washes. Does it soak in right away? The DWR (durable water repellent) treatment has failed.

Quick Reference Care Guide

Every wash cycle:

- Cold water (below 30°C)

- Gentle/delicate setting

- Inside-out placement

- No fabric softener

- Separate from items with hooks or rough textures

Drying protocol:

- Air-dry first choice (away from direct sun)

- Low heat if machine drying (below 60°C)

- Remove right away to prevent wrinkles

- Never iron unless unavoidable

Storage between sessions:

- Don't leave wet gear in gym bags beyond 2-3 hours (bacteria grow 10x in damp, dark conditions)

- Rinse in cold water if unable to wash right away

- Hang-dry before storing to prevent mildew

Replacement timing signals:

- Fabric stays damp 50%+ longer than new

- Sweat no longer spreads across surface

- Odors linger even after washing

- Visible pilling or thinning in high-friction zones

Proper care transforms a $40 performance piece into 3-4 years of reliable service. Neglect drops that to 8-12 months. The wicking technology is there—your job is not destroying it.

Common Buying Mistakes and How to Avoid Them

Most shoppers grab the first "moisture-wicking" label they see. Then wonder why their $60 tech shirt feels like a damp towel after twenty minutes on the treadmill.

This pattern repeats across activewear purchases: 79% of consumers buy items they never use . For workout gear, that means pieces that looked perfect online but failed during the first training session. The fabric doesn't breathe. The fit restricts movement. The "quick-dry" promise evaporates along with your workout motivation.

Here's where money walks out the door:

Mistake #1: Buying based on brand hype alone - 96% of shoppers admit to impulse purchases . Athletic wear falls into this trap often. You see an influencer's sponsored post. The compression leggings look amazing. You click "buy now" without checking fiber content or construction details. Result? Fabric that pills after three washes. Seams dig into your skin during squats.

The fix : Screenshot promising items. Compare fabric makeup across three different brands. Check if polyester content hits that critical 60-85% threshold for real moisture management. Look for specific technology names—not just "performance fabric." Manufacturers like berunclothes list AATCC test results and GSM ratings. Missing technical specs? That's your warning signal.

Mistake #2: Ignoring the price-performance gap - 47% of shoppers buy items on sale regardless of real need . That $120 jacket marked down to $45? There's a reason. Previous season's cut. Failed quality control. Fabric that looked good in photos but performs poorly under stress.

The reality check : Quality moisture-wicking sportswear costs $40-80 for tops, $60-120 for bottoms . Below $30? You get basic polyester without engineered wicking structures. The fabric might be synthetic. But it won't move sweat well. Premium pieces ($150+) often add small performance gains that casual athletes don't need.

Mistake #3: Skipping the fabric weight check - 14% of buyers regret not comparing options before purchasing . You order a "breathable" running shirt. It arrives. The fabric feels thick and heavy. Your summer 10K becomes a sweat-soaked disaster because the GSM was wrong for your climate.

Smart shopping protocol : Match fabric weight to your training environment. Hot climates above 25°C demand under 150 GSM . Moderate conditions work with 150-250 GSM . Cold weather needs 200-250 GSM merino blends . These numbers should appear in product descriptions. Can't find them? Email the brand or skip that purchase.

Mistake #4: Falling for vague marketing claims - 38% of consumers know their purchases are reckless beforehand . Words like "moisture-wicking" and "breathable" appear on everything. From $15 cotton blends to $150 engineered synthetics. Without testing standards or fiber percentages, these terms mean nothing.

Your defense strategy : Hunt for AATCC 195 test mentions or AOTI scores above 0.3 . Real anti-odor workout gear cites ISO 20743 certification with 99%+ bacteria reduction rates. Generic claims without supporting data? That's marketing fluff designed to separate you from your money.

Mistake #5: Choosing cotton for high-sweat activities - This mistake costs comfort, not just dollars. Cotton absorbs moisture then traps it against your skin. Drying time runs 2-3 hours versus 20-30 minutes for quality synthetics. Yet 52% of overspending happens in clothing categories . Buyers grab familiar fabrics without checking performance needs.

The rule : Reserve cotton for light stretching or casual gym visits under 30 minutes. Any cardio session producing continuous sweat demands synthetic moisture management or merino wool blends . Your skin will thank you. Chafing and temperature drops won't ruin your workout.

Mistake #6: Ignoring fit for your specific sport - Running gear fits one way. Yoga wear fits another. HIIT demands different cuts than powerlifting. But 25% of shoppers make unnecessary purchases monthly . This includes workout clothes that look athletic but restrict real athletic movement.

Activity-specific checklist :

- Running/HIIT : Slim-fit tops, semi-compression bottoms, 120-160 GSM weight

- Yoga : Four-way stretch minimum 50%, high-waist leggings with 8-10cm gussets

- Strength training : Raglan sleeves with underarm gussets, mid-to-high-rise waistbands that don't slip during hip hinges

Test range of motion before buying. Raise arms overhead. Drop into a deep squat. Do five high-knees. Fabric pulling or riding up? Wrong cut for your training style.

The bottom line : 74% of Americans admit overspending ruins their financial health . Athletic wear represents a big chunk of that. Purchases fail to deliver promised performance. Slow down. Check fiber makeup. Verify testing standards. Match fabric weight and cut to your workout needs.

Quality gear costs more upfront. But a $70 shirt that performs for 3-4 years beats replacing $25 disappointments every six months. Your workout comfort and your wallet both win.

Conclusion

Finding the right moisture-wicking sportswear isn't about chasing expensive labels. It's about understanding what your body needs. Then match it to the right fabric technology. Check composition labels. Test breathability. Think about your workout environment. You're already ahead of most shoppers who just grab the first "performance" tag they see.

Polyester moisture management works great for high-intensity training. Blends offer everyday versatility. The real game-changer? Spotting quality construction and anti-odor treatments that deliver results.

Your next workout deserves gear that works as hard as you do. Start by revisiting our fabric comparison table. Identify your primary activity needs. Use our quality checklist next time you shop—online or in-store. For engineered performance activewear backed by rigorous testing standards, explore collections from specialized manufacturers like Berun Clothes . Moisture-wicking technology meets thoughtful design there.

The sweat-soaked, uncomfortable workout days? They're behind you now.