Looking for Italian cycling apparel manufacturers? You're after more than suppliers. You want the craftsmanship legacy that's powered pro cycling teams for over a century.

Here's the challenge: Italy's cycling industry has legendary makers and hidden gems. Each claims the best fabrics, fit, and performance tech.

Maybe you're a retailer seeking solid OEM cycling wear partners. Or a brand developer exploring custom cycling apparel options from Italy. Or a cycling fan wondering what makes made in Italy cycling wear worth the price tag. Marketing promises won't cut it. You need a clear comparison of who delivers.

We've analyzed the top six Italian cycling apparel manufacturers. Castelli brings 148 years of innovation. Giordana runs as a family specialist. We looked at their manufacturing capabilities, technical innovations, and minimum order requirements. What sets their Italian cycling craftsmanship apart? We break it down.

We'll show you how to evaluate these manufacturers for your needs. Race-level performance gear? Custom kit programs? You'll know what to look for.

Castelli Cycling – The Innovation Pioneer Since 1876

In 1876, Vittore Gianni opened a small tailoring shop in Milan. His fabric scraps would one day change how cyclists cut through wind. He had no idea.

By the 1910s, Gianni was sewing garments for champion Alfredo Binda. The real shift started in 1935. That's when Armando Castelli joined the staff. Four years later, he bought the business. In 1974, the Castelli brand launched—and cycling clothing changed forever.

Breaking the Wool Tradition

1977 brought the first aerodynamic Lycra® shorts for racing. Before this, cyclists wore wool shorts. Warm. Heavy. Uncomfortable. Castelli's Lycra option gave riders lightness and stretch. Wool could never match that. The shorts debuted at the Milan-San Remo race. Public demand took off right away.

Two years later, Corriere dello Sport gave Castelli the Discobolo prize. The reason? "Futuristic revolution in cyclist clothing." They kept pushing.

1981 saw the first colored Lycra® shorts —a direct challenge to racing rules. The rules said black shorts. Nothing else. Castelli's solution? Riders wore wool tights over colored shorts at the start line. Then they stripped them off. Smart move.

The Technical Breakthrough Years

The 1980s and 1990s brought one innovation after another:

1983 : First sublimation-printed jerseys and windproof jerseys. The peloton's look changed forever.

1984 : First functional thermal winter clothing (Thermodress). Riders could train through cold months without freezing.

1996 : The aerodynamic skinsuit debuted at the Atlanta Olympics. Italy's track cycling team won gold. Mountain biker Paola Pezzo won wearing Castelli.

1997 : The anatomical seat pad (Progetto Y) made classic leather pads old news. It happened fast.

1998 : First modern bib shorts with Y-cut seatpad. Same year, Prosecco wicking fabric launched. This breathable cycling wear material absorbed moisture. ONCE Team got the supply.

The 2000s Revolution

2007 transformed race clothing for Team Saunier Duval. Castelli launched three firsts: the aerodynamic racing jersey (Aero Race), aerodynamic bib shorts (Free), and the lightest pro jersey ever made (Superleggera).

The Giro waistband replaced narrow, uncomfortable anti-slip elastic. No more "sausage effect." This design changed cycling shorts across the industry. It took just four years.

Nano Flex water-repellent fabrics came out in the 2000s. They shed water without those breathability-killing membranes. The Gabba jacket became the first all-weather aerodynamic protection in the peloton.

Professional Pedigree

From 1981 to 1992, Castelli made leader jerseys for both Giro d'Italia and Tour de France. By 1989, much of the pro peloton wore Castelli. Today, they outfit over a dozen professional teams.

What drives this 30+ year innovation run? Maurizio Castelli's passion. His drive to push limits shaped the company's core. He's gone now, but that thinking stays alive. Every fabric choice carries his mark. Every seam placement honors his vision.

De Marchi – 77+ Years of Premium Craftsmanship

De Marchi blends tradition with obsessive attention to detail. Since 1946, this family-run maker has built cycling gear with hands that know fabric. No rushing. No shortcuts.

The Family Workshop Philosophy

Three generations have run De Marchi's production . The founder's grandson still checks quality. Walk into their facility. You'll see seamstresses at the same stations for twenty years. They know how a shoulder seam should sit. How a collar should fold. How fabric tension shifts during six-hour rides.

This isn't mass production. De Marchi makes premium cycling clothing Italy in a workshop setting. Each piece gets individual attention. Seams get checked twice. Fit gets tested on actual riders before patterns hit production.

Italian Design Meets Road Performance

The design team works different here. They don't chase trends. They refine. A jersey pattern might take three years to perfect . They adjust armhole angles by millimeters. Test fourteen zipper spots. Try twenty fabric weights.

Their Italian cycling craftsmanship shows up in odd places. Interior labels use flat-stitched construction. No skin irritation on 100-mile rides. Gripper elastic gets wrapped in soft microfiber. Pocket depths get tested with real gear: phones, energy bars, spare tubes.

The Premium Market Position

De Marchi serves serious cyclists. Custom cycling apparel Italy clients want more than off-the-rack options. Cycling clubs order custom kits with precise color matching. Boutique retailers stock limited seasonal collections.

Minimum orders start at 50 pieces . Higher than many competitors. But their professional cycling clothing Italy delivers fit consistency. Reorders become simple. The same pattern gives the same results, batch after batch.

Santini Cycling – Tech-Driven Performance Specialist

Santini doesn't guess. They measure. Seven full days in wind tunnels. 3D body scans of real riders. Track testing to prove it works. This is how they build race suits that shave seconds.

Their work with Lidl-Trek shows how they do it. The team needed custom time trial skinsuits for both squads. Santini brought riders into the lab. Simone Consonni, the Olympic medalist, tested the first versions. So did Elisa Balsamo, Elisa Longo Borghini, Lucinda Brand, Lizzie Deignan, and Ellen Van Dijk.

Skinsuit development took months . Two versions came out of testing. The warmer fabric version tested fastest for most riders. Hot conditions needed different designs for different body types. They tracked every detail. Wind resistance. Comfort zones. How fabric moved during power output.

Lab Work Meets Race Results

Daan Hoole won Stage 10 of the 2025 Giro d'Italia wearing that Santini skinsuit. A long solo time trial. The kind where air flow matters most. His win proved thousands of testing hours.

Lidl-Trek's women's team has raced in Santini for four years now. That's their fourth season in the UCI Women's WorldTour. The work keeps getting better. Next skinsuit? Testing in the wind tunnel right now.

Beyond Pro Cycling

Santini supplies triathletes who track everything. Giulio Molinari holds three European middle-distance titles . Four Italian titles. He's made it to Hawaii Ironman Worlds twice. His best Italian time? 8 hours, 21 minutes, 52 seconds in 2018. He's won Icon Livigno Xtreme three times.

Marten Van Riel won Ironman 70.3 Dubai in 2022 . He placed fourth at Tokyo Olympics. Second in WTS final rankings. Podium finishes at multiple Superleague races. He tests new gear for Santini.

Nikki Bartlett has fifteen podium finishes. Ironman Lanzarote champion. Ironman Dun Laoghaire 70.3 champion. These athletes don't wear gear for show. They wear what works.

The Lallio Production Engine

Santini makes 7,000+ items each day from their Lallio factory. Eighty percent ships outside of the country. The UCI backs them as official partner. Their four core ideas? Perfect fit. Top performance. Real comfort. Built to last.

No extra words. Just Italian cycling textile makers who test everything twice. The lab work never stops. Neither does the improvement.

Nalini – Custom R&D Excellence

Nalini Lab doesn't follow cycling trends. They create them. 60 years of research backs every fabric choice. The R&D team takes rider feedback and turns it into performance solutions. High-altitude breathing? Cold-weather moisture control? They've tested it. Then they built the fabric to fix it.

The Mantovani Vision Since 1964

Brothers Vincenzo and Claudio Mantovani launched Nalini in 1964 . Their focus? Synthetic fiber quality. Most Italian makers still used wool back then. They led the way with fabric treatments. New printing methods. Technical innovation became what the family stood for.

That mindset still drives the company. Team Picnic PostNL wears Nalini in 2025 —both men's and women's WorldTour squads. Over 35 years of pro team partnerships prove it works. The fabric performs. The fit stays the same. Orders ship on time.

Full Vertical Production Control

The Castel d'Ario factory near Mantova does it all in-house . Fabric weaving. Dyeing. Heat treatment. Print work. Gloves. Socks. Chamois pads. Even cycling shoes. Nothing gets sent out. Every step happens under one roof.

Walk through MOA Sport's facility. You'll see seamstresses stitching custom jerseys by hand. Quality control checks every seam. Sock machines run special patterns. 100% of production stays local . You won't find that often in cycling gear.

Made-to-Order Flexibility

Orders of 20+ pieces per item get full print treatment . Sharp graphics. All the colors you want. Smaller batches under 20 pieces? Digital print handles complex designs. Screen files get saved for two years. Reorders stay easy.

Delivery takes 60 days on average . September through November? You get 40-45 days. January through March stretches to 90 days—peak season. April runs about 60 days. They'll adjust sleeve length. Mix sizes for tops and bottoms. One contact in Italy handles your whole order from design to shipping.

Looking for Premium Cycling Apparel Manufacturing?

Get Italian-quality cycling gear with flexible MOQs. Custom designs, fast turnaround, professional support.

Sportful – Performance-Focused Heritage Brand

Fonzaso sits in the Dolomites' shadow. Small town. Big cycling history. Sportful has made gear here since 1972 . The factory shares walls with Castelli now. Both brands live under the MVC Group. Same innovation labs. Same fabric testing rooms. Different performance ideas.

The Jersey Dominance Strategy

Sportful owns 38.65% of the global cycling jersey market . That's not accident. That's focus. Other brands chase complete kit lines. Sportful perfects the pieces riders need most. Jerseys. Tops. The items touching skin for six-hour rides.

Summer jerseys use moisture-wicking fabrics. They pull sweat before you feel it. Winter tops layer thermal windproof tech without bulk. Every design targets performance basics : integrated pockets that don't sag. Reflective elements placed where car headlights hit. Support zones that don't squeeze.

Lean Manufacturing Meets Direct Sales

Sportful runs efficient . Small core team. High output. They've mastered the high-end road cycling segment. Specialized makers beat mass production here. No bloated staff. No wasted motion.

Direct-to-consumer changed everything . Sportful.co.uk connects buyers straight to Fonzaso. No middleman markup. Faster feedback loops. Design teams hear what riders want. Next season's gear reflects actual use cases.

The Mid-Premium Sweet Spot

Men's cycling apparel drives 52-54% of Sportful's sales . These adopters pay for heritage and performance. They know Italian cycling craft. They've compared Assos, Castelli, Rapha. They choose Sportful for mid-premium pricing that delivers pro-level function. No luxury markup.

Europe accounts for 32-37% of global cycling apparel sales . Sportful thrives here. Italy's cycling culture demands quality. Specialty stores stock 36.68% of all cycling gear sold. These shops trust Sportful. Stock turns fast. Customers come back.

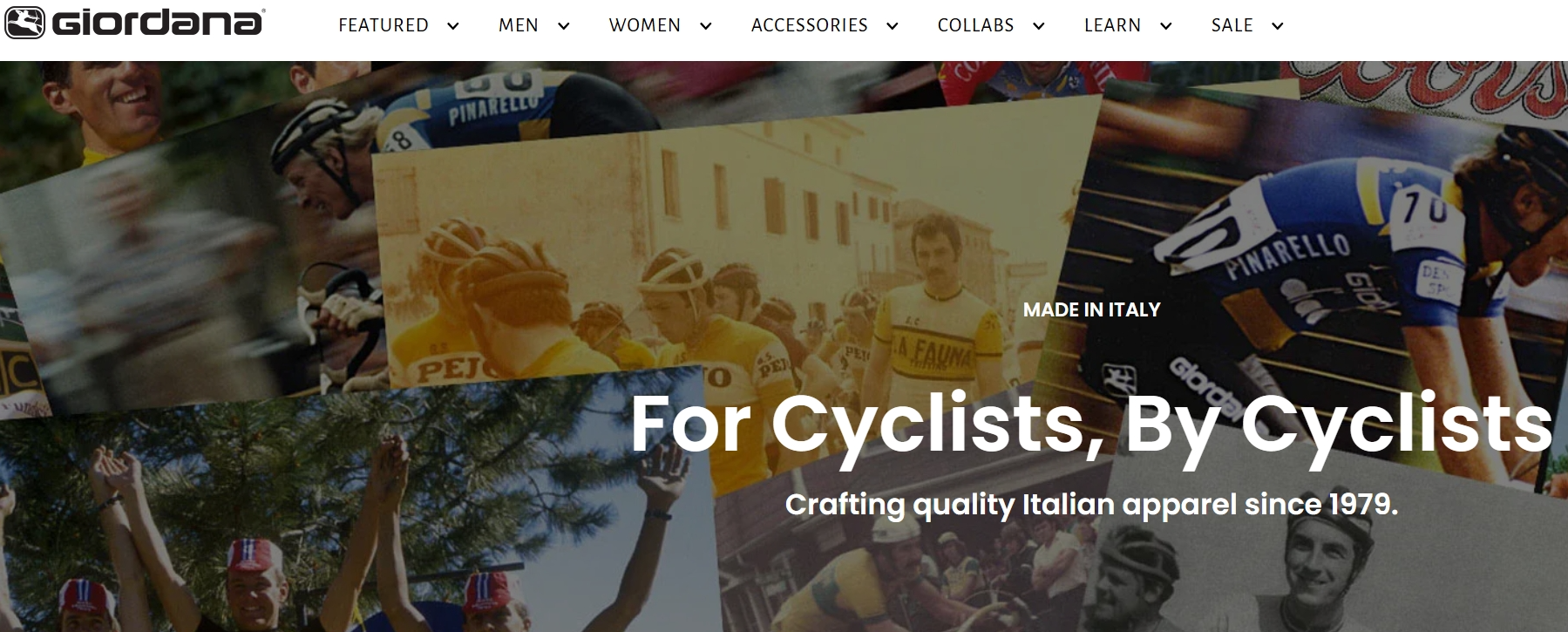

Giordana Cycling – A Three-Generation Production Story

Giordana manages every step. They pick fabrics. Cut patterns. Stitch garments. Check quality. Pack orders. The Giordana team handles it all at their facility. No outsourcing. No shortcuts. Complete control since 1971.

Three Generations of Hands-On Control

Giuseppe Giordana started the business in Santa Monica, California . His Italian roots guided each choice. He picked quality over speed. Craftsmanship beat cost-cutting. This approach continues through three generations today.

The team owns every production step. They buy Italian fabrics straight from mills. New materials get tested in their lab. Patterns are cut on-site. Trained seamstresses sew each piece. Every seam gets checked before it ships. This hands-on approach keeps quality steady across every batch .

Step into their factory. The quality control manager? Twenty years on the job. The head pattern maker learned from Giuseppe himself. Seamstresses shape thousands of jerseys. They know exactly how a shoulder should fit. Years of experience build real skill.

Fast Turnaround on Custom Orders

Total control means fast delivery . A pro team needs custom bibs? They go from design approval to finished samples in two weeks. Not six. The fabric storage sits next to the cutting floor. Pattern changes happen the same day. No waiting on outside cycling wear suppliers.

Italian custom cycling gear clients get true flexibility here. Corporate teams need 100 jerseys? Giordana hits your Pantone colors spot-on. Cycling clubs want unique looks? Their art team works straight with you. Changes cost less because everything stays in-house.

Building Quality from Fabric Up

Premium Italian cycling clothes start with smart fabric picks. Giordana tests how well moisture wicks away. How fabric stretches and bounces back. How colors hold up. How it resists pilling. Fabrics that miss the mark get rejected. No bargaining with outside cucling wear factories. Their standards stand alone.

Chamois pads get extra care. They use multi-density foam. Add germ-fighting treatment. Create smooth edges. Each pad design gets tested for 500+ miles before production starts. Pro riders share feedback. Engineers make tweaks. The Giordana name depends on getting every detail right .

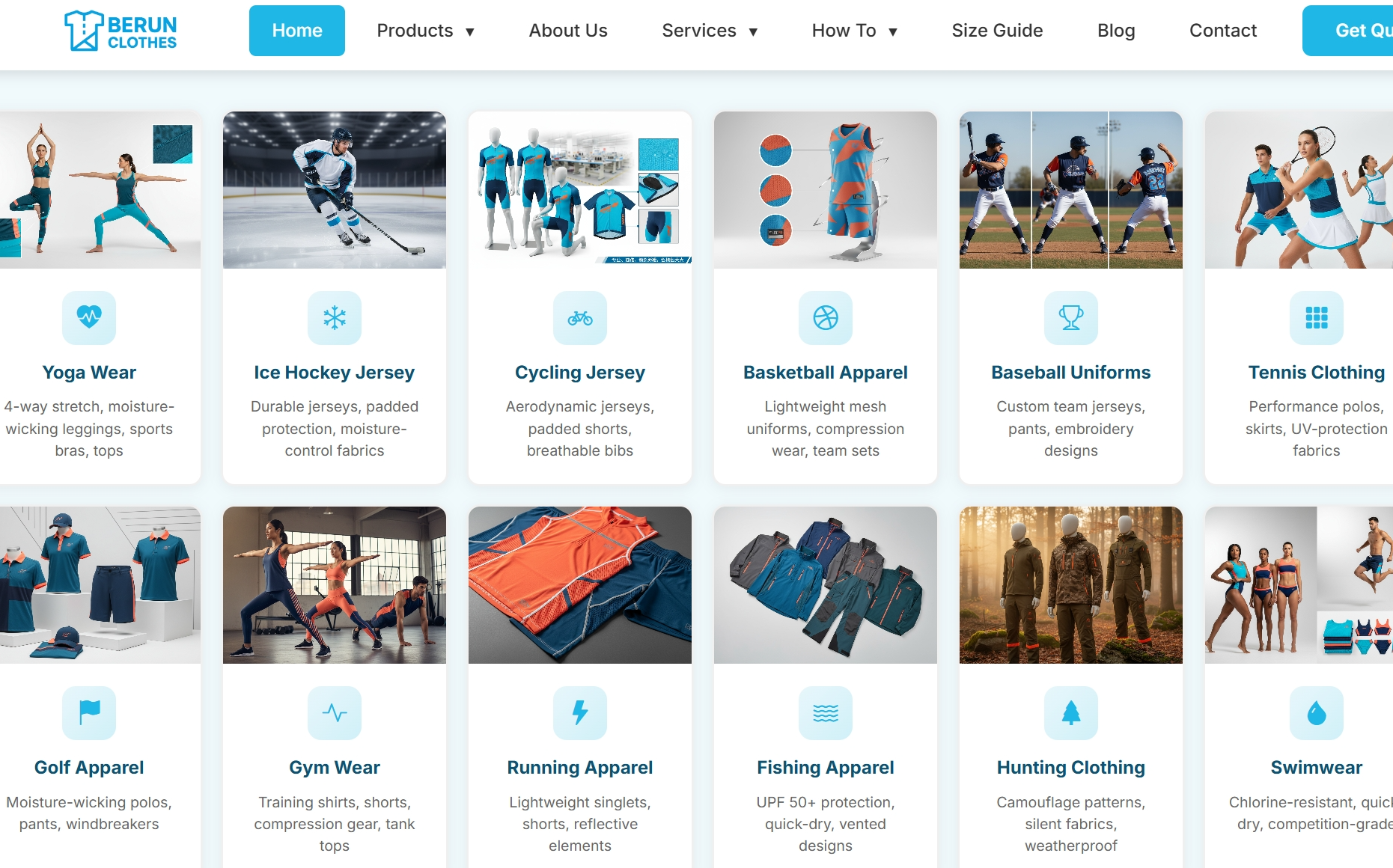

Berunclothes - A Manufacturer with OEM/ODM Manufacturing Experience

Most U.S. cycling apparel factories need 500 pieces minimum. BerunClothes starts at 100. That difference matters for testing new designs or serving niche markets.

The cycling wear factory spans 10,000 square meters in Southern California. 115 skilled workers run three production lines . Small batches use one line. Medium orders take another. High-volume runs get the third. Your 200-piece trial order won't compete with someone's 50,000-unit bulk production.

The Real Cost of Starting Custom

Want to try the ODM cycling clothing (their existing designs)? 200 pieces at $15 each costs $3,000 to start. Pick from proven patterns. Change colors. Add your logo. Samples arrive in 2-4 weeks.

Building from scratch with the OEM cycling wear ? That's 800 pieces at $18 each—$14,400 upfront. Design takes 2-4 months. Sample revisions need another 4-8 weeks. But here's what happens at scale: 5,000+ units cut your per-piece cost by 50% . OEM gives you $1.20 more profit per item than ODM.

Most brands hit ODM break-even at 900 units. OEM? You need 1,700 pieces to recover your investment. The math changes fast after 5,000 units . High-volume production (50,000-100,000 pieces per year) brings OEM costs down to $9-14 per unit. ODM stays at $18-25 for the same volume.

Speed Meets Quality Control

BerunClothes ships 100,000+ custom sportswear pieces each month . Their 21-day average cycle—approved sample to warehouse-ready stock—beats most domestic makers. 94% on-time delivery keeps your launch date on track.

Small batches (100-300 pieces) take four weeks. Orders hitting 1,000-2,000 pieces? Plan for 5-8 weeks. Bulk production adds 4-6 weeks for both OEM and ODM routes.

Every sample goes through squat tests. Wash tests check durability. Color tests verify fastness. Plan for 2-3 revision rounds before production starts. BerunClothes doesn't skip steps to meet deadlines.

Why U.S. Manufacturing Works Now

The U.S. cycling apparel market shifted. August 2025 inventory-to-sales ratio dropped to 1.37 from 1.41 the year before. Shipments hold steady at $607.7 billion per month. Growth comes from value-add now —technical fabrics, custom features, fast turnarounds. Volume isn't the driver anymore.

BerunClothes fits right into that shift. Made in Italy cycling wear gets the heritage points. But custom cycling apparel from a California factory gives you speed, clear communication, and realistic minimums. No ocean freight delays. No language barriers for urgent changes.

You want 150 jerseys for your cycling club? They'll make it happen. Need 10,000 bibs for retail distribution? Same facility handles both.

🚴 Ready to Launch Your Cycling Brand?

From 100-piece minimums to 50,000+ bulk orders. Custom jerseys, bib shorts, and full cycling kits with Italian-quality standards.

Request a Sample →Italian Cycling Apparel Manufacturing: Key Selection Criteria

Italy's cycling apparel industry hit €30.1 billion in 2025. That number comes from 23,078 businesses fighting for your attention. Finding the right cycling wear manufacturing partner takes more than a quick website search. You need clear selection criteria that fit your business goals.

Manufacturing Scale and Capabilities

Minimum order quantities show who you're dealing with . Italian premium cycling cycling wear manufacturers start at 500-2,000 units per order. Castelli's OEM program begins around 1,000 jerseys. Asian factories offer 100-500 piece minimums—but the quality gap is real.

Premium Italian lycra gives UV50+ protection and true 4-way stretch. Standard polyester from mass producers can't match that. The fabric breathability differs. Durability differs too. You feel the difference on mile 80 of a century ride.

Lead times show production complexity . Italian custom kit development takes 10-16 weeks. This covers pattern development. It covers prototyping rounds too. Non-Italian cycling wear manufacturers promise 6-10 weeks. Faster doesn't mean better for seam placement.

Price Structure and Value Positioning

Italian cycling apparel has clear price tiers :

Professional grade : €300+ per kit. UCI-level fabrics. Race-proven patterns.

Road cycling : €150-300. Aerodynamic cuts. Better moisture management.

Gravel/endurance : €100-250. Built to last. Extra padding.

Full custom kits cost €200-500 from Italian makers. Standard producers charge €100-300. You pay for Italian cycling textile manufacturers who test fabrics in wind tunnels. They adjust patterns by millimeters. They check every seam twice.

Italian cycling clothing manufacturers work on 8-22% profit margins. Rising material costs cut 3-5% each year. This pressure drives some brands to cheaper production. The manufacturers who hold quality standards? They earn their premium.

Sustainability and Local Production

Supply chain distance counts now . Italian cycling apparel factories within 200km of Milan and Veneto hubs cut carbon emissions by 30-50% versus overseas production. Veneto region facilities run on 40-60% solar power. That's Italian cycling craftsmanship meeting green goals.

70% of premium Italian cycling producers have GOTS or OEKO-TEX certifications . EU rules push this forward. You're not just buying better gear. You're buying traceable, certified production.

Product Line Coverage Assessment

Smart cycling wear manufacturers cover what riders need:

Jerseys : 80% of market demand

Bib shorts : 60% adoption

Jackets and base layers : 40% of orders

Accessories (gloves, socks): 20% add-on sales

Castelli and Sportful ship across all categories. Smaller makers focus on specific items. Know what your customers need before picking a supplier's limited catalog.

Conclusion

Italy's cycling apparel scene is more than just great manufacturing. Century-old craft meets modern performance tech here. Castelli pushes boundaries with constant innovation. De Marchi focuses on handmade precision. These six manufacturers show that made in Italy cycling clothing means real quality. Serious cyclists and smart retailers have trusted this for generations.

Are you a retailer looking for a solid partner? Maybe you're a team manager who needs custom sportswear gear. Or perhaps you're a cyclist who wants the best. Either way, knowing what makes Italian cycling craftsmanship special helps you choose right. The fabric innovation stands out. The focus on aerodynamics matters. The perfect fit makes a difference.

Want to step up your cycling apparel game? Berunclothes blends Italian design thinking with strong manufacturing. We offer OEM/ODM services and ready-to-ship collections. Our team gets Italian standards. We also give you the flexibility modern brands need.

Contact our cycling apparel specialists today to talk about your vision. We can help you launch a custom line. Or we can source premium Italian-quality cycling kits for your next season.

Start Your Cycling Apparel Journey Today

Whether you need 100 custom jerseys or 50,000 units for retail, we deliver Italian-quality cycling gear with flexible terms.