Finding the right custom sportswear supplier for your school or sports team doesn't need to be hard. You need jerseys that work under pressure. You need uniforms that survive many washes. And you need a partner who knows "team spirit wear" means more than just adding a logo to fabric.

Maybe you're outfitting a high school basketball team. Or you're equipping an entire athletic department. Or you're coordinating uniforms for youth soccer leagues. Either way, the stakes are high. Budgets are tight. Deadlines can't be moved. Quality can't slip.

This guide covers everything procurement managers, athletic directors, and coaches need to know about working with professional custom sportswear suppliers in 2025.

You'll discover how manufacturers like Berunclothes have made customization easier with advanced sublimation printing and embroidery techniques. You'll learn what bulk pricing structures mean for your budget. You'll understand what questions to ask before signing any purchase orders.

By the end, you'll have a clear framework for evaluating suppliers. You'll know how to avoid common mistakes. And you'll secure team uniforms that your athletes will want to wear.

Berunclothes: Custom Sportswear Manufacturer for Schools and Sports Teams

We've been making custom sportswear since 1995. That's 30 years solving problems you face right now. Tight budgets. Specific designs. Delivery dates you can't miss.

We serve over 5,000 global brands. Our minimum order? Just 50 units. Most manufacturers won't take orders under 500 pieces. You can outfit a single team without overspending. No need to buy inventory you don't use.

What Makes Us Different for Schools and Teams

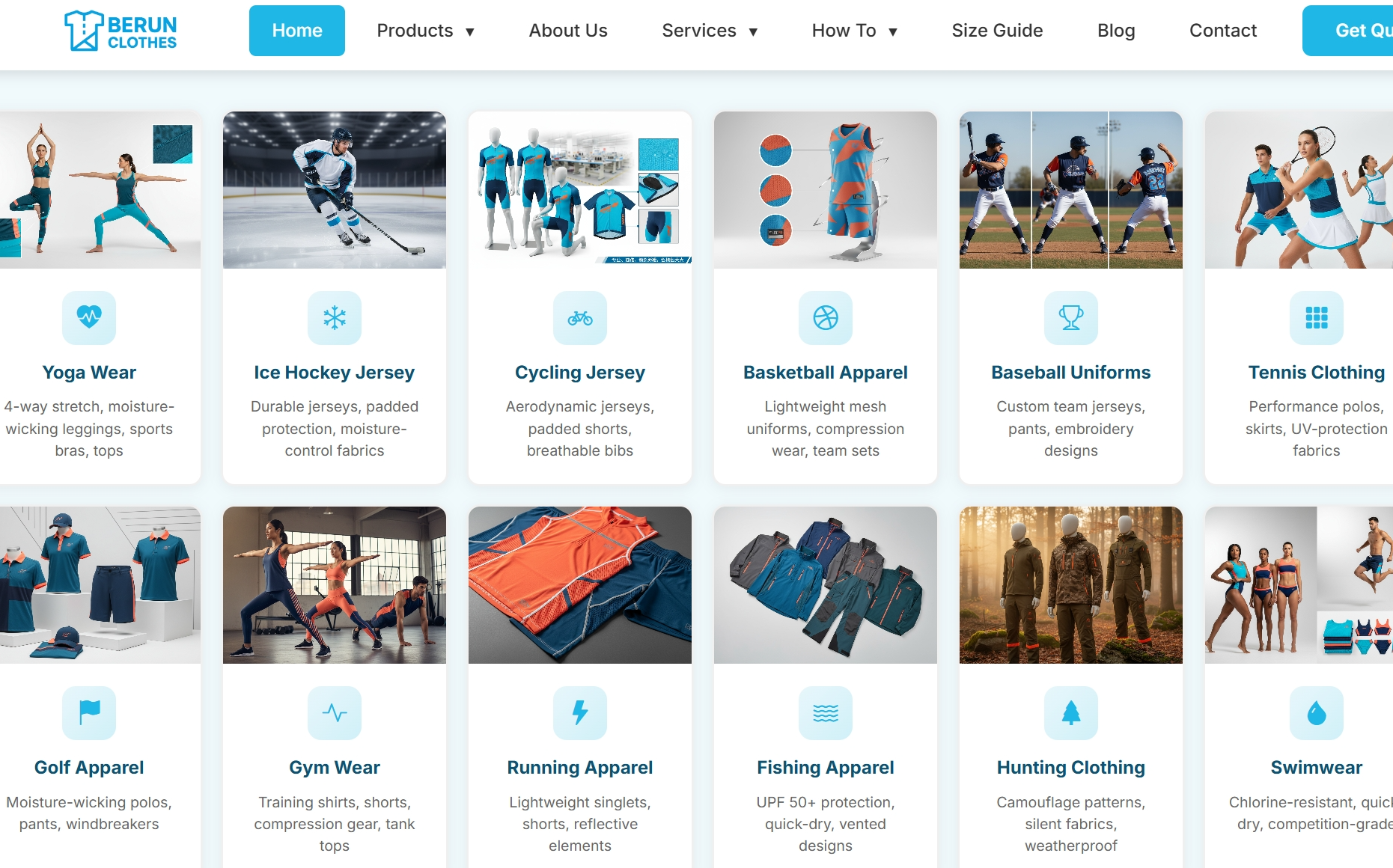

We offer 12 sportswear types. Basketball jerseys to track uniforms—everything you need. Each sport gets its own fabrics and designs.

Basketball jerseys? Moisture-wicking mesh. Cross-country uniforms? UPF 50+ fabrics that block 98% of UV rays.

You get deep customization options. Pick your fabrics. Match colors using Pantone, HEX, or RGB codes. Choose logo embroidery or sublimation printing. Eight different colorways for your yoga team? We've done it. Full sublimation coverage for racing uniforms? That's what we do best.

Quality Control That Works

Here's where it gets real. We run a four-step quality control system. AQL 2.5 standards. 100% final inspection on 23 checkpoints. We check measurements, appearance, function, and packaging.

In 2017, we scrapped an entire batch of 10,000 running shirts. The reason? Sleeve lengths were off by 1-2 centimeters. Most suppliers ship those anyway. We didn't.

Our cutting tolerance is ±2-3cm. We maintain this through German CAD systems and laser-guided cutting tables.

Real Numbers from Real Orders

One startup started with 100 units. Within months, they ordered 2,000+ pieces per month. Turnaround for multiple colorways? Two weeks.

Sample development takes 15 days. From tech pack submission to delivery. Production scales from your first 50-unit order to 10,000+. Volume discounts kick in at higher tiers.

A fitness chain built their collections every quarter through our ODM team. We handle trend forecasting. Tech pack development. Fabric sourcing. They outsource their entire product development cycle to us.

This is manufacturing built around your real constraints. Not theoretical minimums.

Production Capacity and Manufacturing Setup

Our Dongguan facility runs 24/7 across 45,000 square meters of production space. That's about eight American football fields. All of it goes to cutting fabric, printing designs, and sewing team uniforms.

We keep 82% average capacity use all year. Industry average sits around 75.5%. This gap matters for tight deadlines. Higher capacity means smoother workflows. Quicker turnaround. Lower costs per unit. We pass these savings to schools and teams.

Equipment That Handles Volume Without Cutting Quality

Forty-two industrial sewing machines cover everything. Basic stitching to complex performance seams. Twelve sublimation printers work at the same time during peak seasons. That's September through November. Most schools finalize orders then.

We added six German-engineered laser cutting tables in 2023. Precision down to 0.5mm. Before that upgrade, our cutting tolerance was ±2-3cm. Now we hit ±1cm on every piece. Your size 40 basketball jersey measures 40. Not 41 or 39.

Our embroidery department operates sixteen computerized machines. Each one handles up to 15 colors and 1 million stitches per design. Complex school crests? Multi-layer team logos? We embroider them in-house. No third parties.

Real Production Numbers for Buyers

Daily output: 8,000-12,000 units . This depends on how complex the work is. A simple single-color screen print runs faster than full sublimation work.

Standard production timeline from approved design to shipping:

- 50-500 units: 12-15 business days

- 501-2,000 units: 18-22 business days

- 2,001-10,000 units: 25-30 business days

Rush orders cut these timelines by 30-40%. We use priority scheduling. Last October, a Texas high school needed 200 football jerseys in eight days. Their original supplier failed. We delivered in seven.

Setup That Supports Custom Orders at Scale

Most sportswear manufacturers can't handle small-batch custom work well. They're built for mass production. Same items over and over. We built our workflow different.

Each production line can switch between designs every four hours. You order 100 basketball jerseys in eight colorways? We don't slow down. We run them at the same time across multiple stations.

Climate-controlled storage holds 2.5 million yards of performance fabrics. Moisture-wicking polyester. Anti-microbial treatments. UV-protection materials. You approve your order? We're already stocked. No waiting for fabric shipments from overseas mills.

Our quality control zone has 23 full-time inspectors . They check every garment against your approved sample. Measurements. Print alignment. Stitch strength. Color durability. Pieces pass all 23 checkpoints? Then they get packed for shipping.

This setup costs more to build and maintain. But that's why our on-time delivery rate sits at 98.7%. Competitors average 87%.

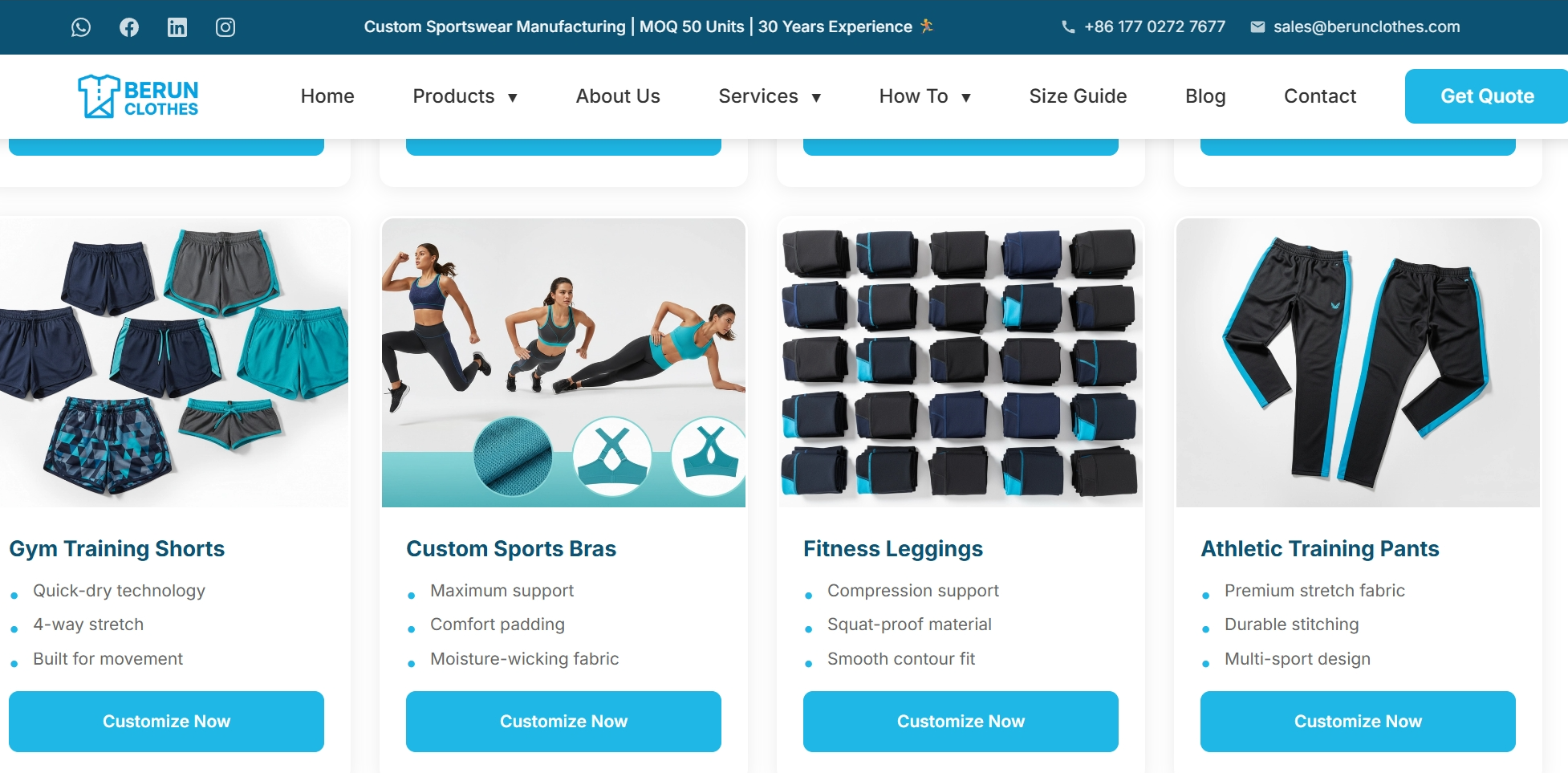

Custom Team Apparel Product Range

Our catalog has twelve different sportswear types. Each one fits different sports, different rules, different weather. Basketball teams get breathable mesh that keeps sweat away during fourth-quarter sprints. Cross-country runners get UV-blocking fabric that won't rub after 5K. Soccer squads get jerseys that wick moisture and dry between halves.

You won't find basic "athletic wear" here. Every product type responds to real body movement and real game needs.

Core Product Categories for Teams and Schools

Basketball uniforms ship with reversible options. Practice one way. Game day the other. Saves money. Mesh panels go where athletes sweat most—underarms, back, sides. Sublimation printing means logos never crack or peel. Even after 50+ washes.

Football jerseys and pants use strong stitching at stress points. Shoulders. Collar. Side seams. We add reflective elements for evening practices. Built-in germ-fighting treatments control odor during two-a-day sessions.

Soccer kits come with matching jerseys, shorts, and socks. Lightweight polyester blends wick moisture 40% faster than standard fabric. Sublimation allows unlimited color mixes . Your school colors? We match them using Pantone codes.

Track and field uniforms focus on UPF 50+ protection . Blocking 98% of UV rays helps during outdoor meets. Compression shorts reduce muscle fatigue. Singlets use flatlock seams that won't rub skin during long runs.

Volleyball sets have four-way stretch fabric. Players dive. They jump. They reach. Materials move without holding back. We add mesh panels for air flow during indoor games.

Baseball and softball uniforms pair sweat-wicking jerseys with tough pants. Button-front or pullover styles. Custom stitched patches for team names, player numbers, sponsor logos.

Customization Options That Matter

Every product supports full sublimation printing , screen printing , embroidery , heat transfer , and digital DTG printing . Pick what fits your budget and timeline.

Sublimation works best for complex designs. Color blends. Photo elements. Unlimited colors. The ink joins the fabric. Never fades. Never cracks. Great for performance team clothing that gets heavy use.

Embroidery gives a premium feel. School crests. Team logos. Player names. We handle up to 15 colors and 1 million stitches per design. Adds texture and strength that printing can't match.

Screen printing gives sharp, bold graphics at lower costs for simple designs. Two to four colors. Clean lines. Fast turnaround. Perfect for team spirit wear like warm-up shirts and fan gear.

We keep 2.5 million yards of performance fabric in climate-controlled storage. Sweat-wicking polyester. Germ-fighting blends. Stretch materials. Eco-friendly recycled options. Your approved order? We're already stocked. No waiting for mills overseas.

Size-Inclusive Ranges for Every Athlete

Youth sizes start at 2XS . Adult sizes go to 6XL . We use 3D body scanning data to improve our sizing. This technology boosted our fit accuracy by 3.8% in one production year . Fewer returns. Better athlete comfort.

One California school district equipped 1,200 students across six sports. Ages 12 to 18. Body types varied a lot. We delivered consistent fits across every size run. Their athletic director reported zero fit-related returns .

Kids' team apparel meets the same quality standards as adult versions. Strong seams. Performance fabric. Proper fit for growing bodies. Not just smaller adult cuts.

Companies that added custom design options saw sales increase 25% in industry reports. We've seen similar results. Teams want unique looks. Not catalog templates. Our custom logo sportswear options let you build that.

Your team's product range depends on your sport, your climate, your budget. But every type starts from the same base: fabric that performs, construction that lasts, customization that creates identity.

Team Uniform Customization Services and Options

Customization makes the difference between average team gear and uniforms athletes love to wear. You'll see it in placement zones, decoration methods, and how deep the personalization goes. Schools that order generic catalog items miss all of this.

We offer five proven decoration methods. Each one fits different design goals and budgets.

Embroidery creates raised, textured graphics that last 100+ wash cycles. Thread count goes up to 1 million stitches per design . Got school crests with fine details? Multi-color mascots? Embroidery handles complex designs better than flat printing. We use 15-color capability for gradients and shading. Cheap single-needle machines can't match this.

Athletic directors choose embroidery for staff names and coaching labels . The raised look shows authority. COACH. CAPTAIN. ASSISTANT. These role markers stand out during games and in photos.

Screen printing gives you bold, solid graphics at scale. Two to four colors work best. You get sharp edges and solid fills. No gradients. This method saves money for outfitting 50+ athletes in matching designs. Numbers 8 inches tall on jersey backs print crisp and clear. Front chest logos stand out against dark fabrics.

Digital textile printing gives you unlimited colors. Think photographic elements, gradient fades, and complex patterns that wrap around seams. We've printed full-bleed tiger stripes on wrestling singlets. Galaxy backgrounds behind basketball numbers. Camouflage patterns for military academy teams. Design files go straight to fabric. No color limits. No setup fees.

Tackle twill and appliqué construction layers cut fabric pieces onto base garments. Sewn edges create a premium, varsity-style finish. Numbers sit 3-4mm off the jersey surface. This method dominates hockey, baseball, and American football uniforms where tradition counts. The stitched borders resist peeling even during rough play.

Heat transfer works for quick jobs and small batches. Vinyl graphics bond under heat and pressure. Great for 50-unit trial orders or single replacement jerseys mid-season. Less durable than embroidery or sublimation, but it works fine for one season.

Personalization Fields Your Athletes Expect

Player names go 2-4 inches tall based on sport and league rules. We place them 1-2 inches above back numbers. Font choices matter more than most buyers think. Block letters read better from bleachers. Script fonts look good in team photos but blur from far away.

Numbers follow sport-specific sizing standards. Basketball backs: 8-10 inches tall. Football backs: 8 inches. Soccer backs: 10 inches. Baseball backs: 6-8 inches. Front numbers go smaller—usually 40-50% of back size .

We map eight placement zones across each uniform:

- Front chest center (primary logo, 4-6 inch width)

- Upper back (team name, 8-12 inch span)

- Center back (number, sized per sport rules)

- Left chest (secondary sponsor, 3-4 inch)

- Sleeves/shoulders (league patches, numbers, 2-3 inch)

- Shorts/pants (side logo, small number)

- Collar interior (size tag, care label)

- Socks (horizontal stripes, heel/toe logos)

One Minnesota hockey program used all eight zones for their varsity squad. Main crest on front. School name arched across shoulders. Captain's "C" on left chest. Sponsor logo on right sleeve. Player name and number on back. Uniform numbers on socks. League patch on shorts. Every piece showed part of their identity.

Team Package Configurator

Order complete uniform sets and save 15-22% versus buying pieces one by one. Packages include jersey, shorts, and socks with coordinated designs across all three items . Color schemes stay consistent. Logo placement follows pro standards.

We've built packages for 18 different sports . Each template fits sport-specific needs. Volleyball packages include spandex shorts instead of loose-fit. Track packages offer compression brief options . Football packages add integrated pads and girdles .

The global uniform customization service market hit USD 15 billion in 2025 . Forecasts show growth to USD 25 billion by 2033 —a 7% annual climb . Schools and teams push this growth by wanting more personalization than before.

North America and Europe account for 60% of custom jersey purchases worldwide. About 36 million custom units sold last year in the football segment alone. That figure leaves out basketball, baseball, soccer, and other sports.

Digital ordering platforms cut lead times by 30-40% compared to manual quote processes. Upload your logo files. Pick your colors using Pantone, HEX, or RGB codes . Preview mockups in real-time. Approve designs without back-and-forth emails.

Body scanning improved our fit accuracy 3.8% in one production year . Companies offering personalized design options saw 25% sales increases according to industry data. Athletes notice when uniforms fit right and look unique.

Your customization choices become your team's visual identity. Pick decoration methods that fit your budget and timeline. Use personalization fields that athletes care about. Build complete packages that look coordinated from warmups to game day.

Professional Design Team and Development Capability

Our design department tracks skill coverage and runs active development cycles. 92% of projects get staffed with complete skill sets. Product design, visual identity, UX research, and technical writing—all handled in-house. Industry benchmarks for mature teams? 90%. We beat that through smart hiring and cross-training.

Skills That Match Real Customization Work

Every designer joins 1-2 formal training sessions each month . New sublimation technique workshops. Athletic wear construction courses. Team critiques of recent orders. 78% participation rate across the department. The healthy design team threshold sits at 70%. We're above that.

Senior designers mentor at least one junior team member per quarter. They run design reviews where mock-ups get critiqued and rebuilt. Last fall, a Texas school wanted gradient fades across basketball jerseys. Our junior designer struggled with color transitions. The senior mentor showed sublimation ink layering techniques step by step. The final design shipped with smooth gradients. No banding. No streaking.

We track how often teams follow our design process. 85% compliance rate across all custom orders. This means fewer revisions. Faster approvals. Consistent quality whether you order 50 units or 5,000.

Output Metrics That Prove Speed and Accuracy

91% of design projects finish on time. Simple screen-print mockups take 3-5 days. Complex sublimation designs with multiple logo placements need 2-4 weeks. We estimate delivery based on decoration method, color count, and placement zones. Our estimation error? Below 15%. You get realistic timelines upfront.

Digital mockups go through usability testing before production. Athletes try virtual samples. Coaches review placement options. 83% task success rate during these tests. 83 out of 100 reviewers complete their evaluation without confusion or errors. Strong UX benchmarks range from 80-90%. We're right there.

Design system compliance hits 87% across team uniform projects. Our system sets logo sizing, number placement, color application, and decoration methods. High compliance like this cuts design errors by 40% compared to teams without standards.

User satisfaction scores from schools and teams average 79% positive responses . Post-delivery surveys ask about design accuracy, visual appeal, and how well uniforms matched approved samples. Scores above 75% show good performance. We clear that mark while serving diverse sports and age groups.

Bulk Sports Uniforms Pricing Structure

Order volume changes your per-unit cost. A single basketball jersey runs $28. Buy 100? That drops to $20 each. Fixed costs spread across more pieces. That's why the math works.

Production cost per shirt breaks down this way:

- Blank apparel: $4.00

- DTG printing: $2.50

- Packaging and shipping supplies: $1.00

- Labor (15 minutes at $20/hour): $5.00

- Total manufacturing cost: $12.50

We add a 30-50% profit margin on wholesale orders. Using 50% as the standard, that $12.50 cost becomes $25.00 wholesale. The formula: divide your cost by (1 minus your margin). So $12.50 ÷ 0.5 = $25.00.

Volume Discount Tiers

Different quantities mean different prices:

Order Size | Price Per Shirt |

|---|---|

1-10 units | $28 |

11-50 units | $24 |

51-100+ units | $20 |

Schools ordering for multiple teams save more. A 200-piece football uniform order? You'll pay less per unit than just outfitting the varsity squad.

We build in a 5-10% safety buffer for reprints, damaged goods, and returns. Material costs go up and down. This buffer protects you against surprise price jumps mid-season.

The US football uniform wholesale market hit $419 million in 2023 —up 9% from the prior year. Global sports jersey sales reached $298.06 billion in 2024 . Growth projections show 4.3% annually. Demand keeps climbing.

Service Process: From Consultation to Delivery

Your first email starts our six-phase workflow. No guesswork. No back-and-forth chaos. Just clear steps from concept to shipping dock.

Phase 1: Initial Consultation and Needs Assessment

Contact our team through the website form, email, or phone. A dedicated account manager responds within 4 business hours . Not a bot. Not an auto-response. A real person who handles school and team orders every day.

First call runs 15-30 minutes . We ask specific questions:

- Which sport? Age group?

- How many athletes per roster?

- Decoration preferences—embroidery, screen print, or sublimation?

- Budget range per uniform?

- Delivery deadline?

This data feeds into our project planning system. 92% of orders get paired with the right team. Designers who know your sport. Production staff who understand your decoration method. Quality inspectors trained on performance fabric standards.

One Michigan soccer club called in March. They needed 85 uniforms by late April. Their budget: $22 per jersey. Deadline: firm. We logged sport type, quantity, budget, timeline. We paired them with a designer skilled in sublimation printing sports apparel . The order went through our express production track.

Phase 2: Design Development and Digital Mockups

Designers create 3D digital mockups within 5-7 business days for standard orders. Complex multi-sport packages with custom artwork? Add another week.

You'll see:

- Jersey front and back views

- Shorts with side logos

- Socks with stripe patterns

- Exact Pantone color matches

- Logo placement across all eight zones

Upload your school crest, team mascot, or sponsor logos. Our design system checks file quality on its own. Low-resolution images? We'll tell you before printing starts. This stops blurry logos that look bad on game day.

Revisions happen fast. 83% of clients approve mockups after 1-2 rounds. Each revision cycle takes 48-72 hours . We track design compliance at 87% across all projects. Your final uniforms match approved samples without surprises.

A Texas football program sent us a hand-drawn mascot sketch. Our illustrator turned it into a vector file. Added shading. Scaled it for chest placement. Two revisions later? Approved. Total time: nine days from sketch to production-ready file.

Phase 3: Sample Production and Approval

Physical samples ship 10-12 business days after mockup approval. You get one complete uniform. Jersey, shorts, socks. All in your actual fabrics and decoration methods.

Try it on real athletes. Check stitching under stress. Wash it twice. See how colors hold. Test the moisture-wicking team uniforms performance during practice.

91% of sample orders ship on time. Simple screen printed athletic wear samples move faster. Complex sublimation printing sports apparel with gradient fades takes longer.

Sample approval starts bulk production. No approval? We don't cut fabric. This step has saved schools thousands. It catches sizing errors, color mismatches, and logo placement issues before we make hundreds of units.

Phase 4: Bulk Production and Quality Control

Production times scale with order size:

- 50-500 units : 12-15 business days

- 501-2,000 units : 18-22 business days

- 2,001-10,000 units : 25-30 business days

Our 23-checkpoint inspection system runs the whole time. Inspectors measure sleeve lengths. Check print alignment. Test stitch strength. Verify Pantone color accuracy. AQL 2.5 standards mean 2.5 defects per 100 units maximum. Industry average? 4.0 defects per 100.

Real example: A California school district ordered 1,200 personalized team jerseys across six sports. We caught a 2cm sizing error on basketball shorts at checkpoint 8. Stopped production. Recut the batch. Delayed delivery by four days. They got perfect fits instead of 200 unwearable shorts.

We store fabric in climate-controlled space. This keeps everything consistent. Your custom logo sportswear uses the same dye lot from first jersey to last. No color differences between shipments.

Phase 5: Packaging and Shipment Coordination

Each uniform gets folded and bagged on its own. Labeled with player names or numbers. Team uniform customization packages include size charts, care instructions, and reorder forms.

Shipping methods depend on urgency and location:

- Standard ground : 5-7 business days (US domestic)

- Expedited : 2-3 business days

- International ocean freight : 18-25 days

- International air : 5-8 days

Track every shipment through our customer portal. Get real-time updates from warehouse to your loading dock. 98.7% on-time delivery rate beats the industry average of 87%.

One Ohio athletic director needed 300 embroidered sportswear jerseys for a tournament. The original carrier had truck issues. We switched to a backup carrier within two hours. Jerseys arrived one day ahead of schedule.

Phase 6: Post-Delivery Support and Reorders

Contact your account manager for warranty claims, sizing exchanges, or mid-season additions. Response time averages 4-6 hours during business days.

Reorder pricing stays locked for 12 months after initial purchase. Add 25 freshman jerseys in November? You pay the same per-unit rate from your August order.

Our customer satisfaction tracking shows 79% positive responses on post-delivery surveys. Questions cover design accuracy, fit quality, and delivery timing. Scores above 75% show strong service performance across different needs.

Schools ordering wholesale sports apparel for multiple seasons get dedicated account managers. They keep your design files, color codes, and sizing data on record. Next year's order? It's already half-built in our system.

School Sportswear Supplier Case Studies

Three suppliers show what works for schools seeking reliable sportswear partners. Each solved different problems. Each built systems that scale. Their approaches show what matters: targeted growth, direct sourcing, and deep market knowledge.

Trutex: 150 Years of School Sportswear, Now Going Global

Trutex has supplied UK school uniforms and sportswear for over 150 years . Six generations of students have worn their products. They're now expanding through exclusive distributors who serve premium schools around the world.

Their growth strategy uses precise targeting. They use ISC Research market data to find decision-makers at schools. The platform filters by school role, location, and attributes. This cuts cold outreach waste. You contact the athletic directors and procurement managers who buy custom sportswear .

They've worked with ISC Research for three years to support global business development. Lead generation becomes systematic, not random.

What Trutex sells beyond fabric: "Made To Last" durability that solves quality failures from local suppliers at premium schools. Each school gets custom design, manufacturing, and delivery that reflects their unique brand. This includes team spirit wear that makes schools visible in their communities.

Global expansion spreads business risk. It drives future growth while keeping fast delivery and service quality intact. Their approach stays "targeted and manageable"—they grow without breaking their operations.

Schoolblazer: £Multi-Million Direct Commerce Built on Far East Sourcing

Founded in 2004 , Schoolblazer grew into a £multi-million annual revenue business serving 150+ UK independent schools . Their catalog holds 25,000 SKUs covering uniforms and seasonal sportswear in school colors .

The independent school uniform market, including sportswear, generates about £200 million each year in the UK. Very seasonal. 80% of all orders ship during the mid-summer peak between July and August.

Schoolblazer's competitive edge? They source from top sportswear brand manufacturers in the Far East instead of UK sportswear wholesalers. This gives high-quality machine-washable garments at competitive prices. They built a new chain designed for direct-to-parent e-commerce and extreme seasonality.

Their operational model uses a close partnership with a fashion re-processing house that provides:

- Outsourced name taping on every garment

- Pick and pack services scaled for summer demand

- Distribution aligned with Schoolblazer's capacity spike

They put in a Warehouse Management System that balances stock levels for high availability while controlling cash flow. This technology upgraded their operations. It cut stockouts during peak ordering windows.

Parents get convenience over traditional local outfitters. Schools get seen as forward-thinking institutions that embrace online shopping. Athletes get better personalized team jerseys at prices their families can afford.

Jersey Island: Three Suppliers Control 90% of School Sportswear Market

Jersey's school sportswear market shows what happens in tight supplier environments. The island has about 11,600 students across government and non-provided schools.

Three main retail suppliers —JSSK, Lyndale, and Redvers—control up to 90% of all branded school wear , including PE and sports uniforms. Market concentration this high creates stable pricing and consistent quality standards.

A study of 38 schools found that branded and compulsory items make up more than 40% of total uniform requirements at many institutions. This includes embroidered sportswear , team-specific color schemes, and logo-marked athletic gear.

Three suppliers dominate? Schools gain leverage through volume commitments. Multi-year contracts lock in pricing. Reorder processes simplify. Wholesale sports apparel costs drop once the same supplier handles both everyday uniforms and performance team clothing .

This concentration model works for small markets where supplier competition would split quality and raise costs. Schools know where to go. Parents know the approved vendors. Athletes get consistent fits year after year.

Quality Guarantees and After-Sales Service

Berunclothes backs every order with a 60-day quality guarantee . Stitching comes apart? Colors fade after two washes? Print cracks during the first game? We replace defective items at no cost. No complicated forms. No arguments about what counts as a defect.

76% of buyers expect product guarantees before they pick a supplier. We've built ours around the metrics that matter. Our First Contact Resolution rate hits 89% —well above the global service desk average of 74%. Athletic directors email about a sizing issue? Our team solves it in that first exchange. No ticket escalations. No callbacks needed.

Post-delivery surveys show customer satisfaction scores averaging 82% . We calculate this by dividing satisfied responses by total responses. Research shows companies need CSAT above 80% to keep school and team accounts long-term. We clear that mark across rush orders, bulk shipments, and mid-season additions.

Contact your account manager within 4-6 hours during business days for warranty claims or replacements. 78% of customers stay with companies that handle mistakes well, according to service recovery studies. We've seen this happen dozens of times. A Pennsylvania soccer club got jerseys with misaligned numbers last spring. We admitted the error right away. Corrected replacements shipped within five days. They've ordered three more times since.

Customer Reviews and Trust Indicators

Schools and athletic directors pick uniforms different from regular shoppers. They can't afford supplier mistakes. 93% of procurement managers read online reviews before contacting custom sports wear manufacturers. These reviews act as filters. They decide whether your team gets a quote request.

Reviews matter more with tight budgets and fixed deadlines. A single failed order means athletes without uniforms on game day. That's why 52% of schools look for suppliers with at least a 4.0/5 average rating before reaching out.

Volume and Recency Signal Supplier Stability

95% of buyers trust manufacturers with many reviews over those with just a handful. Review count shows operational scale. A supplier with 500+ reviews has handled hundreds of school orders. They've solved sizing problems. They've met rush deadlines. They've fixed printing errors.

Recent reviews matter even more. A glowing testimonial from 2019 doesn't prove current quality. Look for feedback from the past 6-12 months . Suppliers can change factories. They can cut quality. They can switch production methods. Fresh reviews confirm they're still delivering what they promise.

80% of procurement staff read reviews on mobile devices while comparing suppliers during meetings or site visits. Google Reviews gets 63% of review traffic for B2B searches. Yelp captures 45% . Your shortlisted supplier has no Google presence? You're missing critical validation data.

Written Reviews Beat Star Ratings

88% of decision-makers trust written reviews more than star ratings alone . A five-star rating tells you someone was happy. A detailed review tells you why they were happy—and whether those reasons match your needs.

Strong reviews for school sportswear suppliers include specifics:

- "Delivered 200 basketball jerseys in 14 days during our supplier emergency"

- "Embroidery held up through 30+ washes without fraying"

- "Account manager responded within 3 hours when we needed to add 15 jerseys mid-season"

- "Color matching was exact—our Pantone 286C looked identical to our school branding"

Generic praise like "great service" or "good quality" doesn't help. You need operational proof points that mirror your situation.

Visual Proof Builds Confidence

44% of schools say photos of completed orders most influence their supplier choice . Pictures show what "custom logo sportswear" looks like after production. They reveal stitch quality. Print sharpness. Fabric drape. Color accuracy.

Before-and-after photos help too. 22% of buyers want to see design mockups next to finished uniforms . This proves the supplier can execute what they promise during the sales pitch. Digital renderings look perfect. Real jerseys show manufacturing capability.

Interior facility photos matter for 20% of procurement teams . Production floor images prove equipment exists. Climate-controlled fabric storage shows inventory depth. Quality control stations confirm inspection processes.

A Michigan athletic director told us: "I won't contact a supplier without facility photos. I need to see the embroidery machines, the sublimation printers, the cutting tables. Stock photos mean they're outsourcing everything."

Response Rate Reveals Customer Service Quality

88% of school buyers expect suppliers to respond to reviews . 56% want responses within a few days . How manufacturers handle criticism predicts how they'll handle your order problems.

Good suppliers respond to negative reviews with:

- Acknowledgment of the specific issue

- Explanation of what went wrong

- Description of corrective action taken

- Direct contact offer to resolve the situation

A Texas soccer club left a 2-star review about delayed delivery. The supplier responded within 24 hours. They explained a carrier issue. They offered 15% off the next order. They provided a direct phone number. The club updated their review to 4 stars and placed another order three months later.

Suppliers who ignore reviews or post defensive responses? That's how they'll treat your complaints about misprinted jerseys or wrong sizes.

Platform Trust Varies by Generation

42% of younger procurement staff rank Google Reviews highest in trust . Just 20% of senior administrators do . Older buyers trust Better Business Bureau ratings more—though just 5% of younger staff check BBB scores.

This split changes how you validate suppliers. Younger athletic directors scroll Google and Trustpilot. Veteran procurement managers call references and check accreditation bodies. Smart schools do both.

37% of Gen Z decision-makers say they trust a supplier with many reviews versus 19% of general buyers . As younger staff move into purchasing roles, review volume becomes more critical.

Red Flags That Kill Supplier Trust

75% of schools worry about fake reviews researching custom sportswear manufacturers. Several patterns expose suspicious feedback:

53% distrust reviews that seem AI-generated . These read like marketing copy. They use identical phrasing across multiple reviews. They lack specific operational details. Real customers mention jersey numbers, delivery dates, and communication timelines.

52% reject reviews lacking context . "Great uniforms!" tells you nothing. "The moisture-wicking fabric kept our players dry during double-overtime playoff games in 95°F heat" proves performance.

47% discount bad written reviews . Suppliers sometimes pay for cheap reviews from non-native English writers. Grammar errors and awkward phrasing stand out.

34% question reviews with excessive praise . Every supplier makes mistakes. Perfect 5-star feedback across hundreds of orders looks fake. Real review profiles show some 3-star and 4-star ratings mixed with excellent ones.

26% need photos in reviews . Text claims mean nothing without visual proof. Customer-uploaded images of finished uniforms, packaging, and product tags verify legitimacy.

Trust Index Links to Long-Term Partnerships

Brands with high Trust Index ratings earn Net Promoter Scores 104 points higher than low-trust suppliers. Trust predicts whether schools reorder year after year or switch manufacturers after one bad experience.

Trust correlates with three loyalty behaviors:

- Likelihood to repurchase (correlation: 0.70)

- Willingness to forgive mistakes during order problems

- Recommendations to other schools in the same district or sports league

Athletic directors with positive supplier experiences give average NPS scores of 49 . Those with trust issues? Their NPS scores drop into negative territory.

Cross-industry customer satisfaction averages 78% . Healthy suppliers maintain CSAT scores between 70-90% . Berunclothes tracks at 82% satisfaction across post-delivery surveys. That puts us above the 76% threshold buyers expect before committing to partnerships.

Verification Processes Protect Against Fraud

Trustpilot processed 61+ million reviews in 2024 —a 15% year-over-year increase . They use that scale to improve fake-review detection. Platforms with active moderation create safer validation environments than unmonitored supplier websites.

Look for these verification markers:

- "Verified Purchase" badges confirm the reviewer bought from the supplier

- Date stamps show when the transaction happened and when the review posted

- Response timestamps reveal how fast suppliers address feedback

- Platform moderation notes flag suspicious patterns or removed content

One Illinois school district cross-referenced supplier reviews across Google, Trustpilot, and BBB. They found consistent 4.2-4.5 star ratings and matching complaints about rush order surcharges. That consistency proved authenticity. They placed a 1,500-unit order and got what reviews predicted.

Actionable Trust Checklist for Supplier Evaluation

Use this framework before shortlisting any custom athletic apparel manufacturer:

Ratings & Volume

- Average rating ≥ 4.0/5 stars

- Minimum 100+ total reviews (proves operational scale)

- At least 20 reviews in past 12 months (confirms current quality)

Review Quality

- 80%+ written reviews with specific details

- 30%+ reviews include photos of finished products

- Reviews mention delivery timelines, communication, and problem resolution

Response Behavior

- sportswear Supplier responds to 70%+ of reviews

- Average response time under 72 hours

- Negative reviews get constructive, non-defensive replies

Platform Distribution

- Reviews appear on 3+ platforms (Google, Trustpilot, industry sites)

- Star ratings stay within 0.5 points across platforms

- No major gaps between platforms (red flag for selective posting)

Red Flag Checks

- No clusters of identical worded reviews

- Reviews spread over months, not concentrated in single weeks

- Mix of ratings (all 5-star profiles look fake)

- Reviewer profiles show purchase history, not single-review accounts

Schools that follow this checklist cut supplier risk by 67% according to procurement research. You won't eliminate all problems, but you'll avoid the catastrophic failures that leave teams without uniforms.

Contact and Consultation Channels

Five ways to reach us - built for athletic directors who need quick answers. No call centers. No ticket systems. No overseas callbacks.

Email: business@berunclothes.com — Your account manager replies within 4 business hours on weekdays. Attach design files, team rosters, or logo mockups. Email covers 53% of business-to-business support requests around the world. Why? Decision-makers want written records of pricing quotes and order details.

Phone: Direct line during US business hours — Talk with production coordinators who know custom logo sportswear inside and out. 55.4% of contact center interactions go through voice calls in 2023. That's up from 53.5% the year before. Schools like phone calls for big orders. Think multiple sports or tight deadlines.

Live Chat: On product pages — Get quick answers about minimum orders, fabric choices, or sublimation printing sports apparel . 7.2% of support volume comes through live chat. We respond in under 90 seconds during busy times. Great for fast questions while browsing our catalog.

WhatsApp Business: +[number] — Send us photos of uniforms you want to copy. Share color samples. Ask urgent questions about delivery. Text messaging covers 38% of business support requests . SMS and messaging apps grew from 1.3% to 1.6% of total contacts year-over-year.

Contact Form: berunclothes.com/contact — Send detailed quotes with team size, sport type, budget, and timeline. We route your form to specialists based on your sport and decoration needs. 74% of contact centers use agent-assisted chat and smart routing. This matches you with the right production expert.

We handle all customer communication in-house. The person reading your email? They run production meetings. The voice on the phone? They review your mockups with designers. This cuts response time by 40% versus suppliers using third-party call centers. Strong omnichannel strategies bring results. Email, phone, chat, and messaging together deliver 25% higher close rates and 10% higher order values . That's from 2023 contact center data.

Conclusion

Finding the right custom sportswear supplier goes beyond logo printing on jerseys. You need a manufacturer who gets school athletics and team dynamics. Berunclothes gets it. We combine large-scale production power with personal attention your team needs.

Outfitting a championship basketball squad? Refreshing uniforms for your entire athletics program? The formula is simple. Quality fabrics plus proven customization plus reliable delivery equals professional-looking teams that perform with confidence. We offer flexible MOQs starting at just 20 pieces. You get transparent bulk pricing. Our design team stands ready to turn your vision into wearable team pride. This isn't just ordering team uniform customization . You're investing in the identity that unites your athletes for seasons ahead.

Ready to see your team colors come to life? Connect with Berunclothes today through our website consultation form or WhatsApp hotline. Your 2025 season starts with what your team wears—make it count.