The global sportswear industry has grown into a $380+ billion market. Most people recognize the flashy retail brands, but the real powerhouses stay hidden in plain sight. Finding reliable activewear manufacturers is the first critical step for any brand looking to capture a slice of this massive pie.

Behind every Nike swoosh and Adidas stripe lies a network of elite manufacturers. They turn raw fabric into performance gear at massive scale. Some produce over 100 million garments each year. These manufacturing giants do more than stitch clothing; they are shaping the future of athletic wear through advanced automation, green innovation, and master-level OEM/ODM services.

Are you sourcing suppliers for your activewear startup? Maybe conducting market research? Or just curious about who dominates this trillion-dollar world? To succeed, you need a partner who understands the nuances of being a top-tier fitness clothing manufacturer. We've analyzed revenue data, production capacity, tech capabilities, and market influence. Here is the ranking of the world's largest players providing the infrastructure for your favorite athletic brands.

Crystal International (Hong Kong)

Crystal International doesn't chase headlines; they chase results. While most activewear manufacturers talk about sustainability, this Hong Kong giant backs it up with real numbers. They are redefining what it means to be an eco-conscious fitness clothing manufacturer on a global scale.

Here's what sets them apart: 90% absolute emissions reduction by 2050. Not a vague promise. The Science Based Targets initiative validated this commitment. They've already cut 4.7% of total carbon emissions year-over-year in 2023. Their Cambodia denim factory saves 350 tonnes of CO2 each year through smarter drying systems.

Production scale meets precision. Crystal runs facilities across Vietnam, China, Cambodia, Bangladesh, and Sri Lanka. They make everything from denim to sportswear, outdoor gear to intimates. As one of the leading sportswear manufacturers, they prove that volume without innovation is old news.

Smart Manufacturing Revolution

Crystal's Vietnam denim factory gets a complete digital upgrade by mid-2026. Smart warehouses, automated guided vehicles, and RFID tracking throughout production are the new standard. The result? They plan to nearly double denim capacity by 2029.

Their knits division added 300+ automated machines and robots since 2023. Basic T-shirt production time dropped 34% compared to 2020. This efficiency allows them to serve clients needing high-volume custom sportswear solutions with faster production, lower costs, and better quality control.

Water & Materials Game Plan

The water numbers tell a strong story: 23% less freshwater per garment year-over-year. Their Vietnam denim factory now runs on 60% recycled water. Material sourcing shows the same level of commitment, with 40% recycled polyester in sportswear fabrics. They're not just making clothes; they're building the future of green, scalable apparel production.

Berunclothes (China)

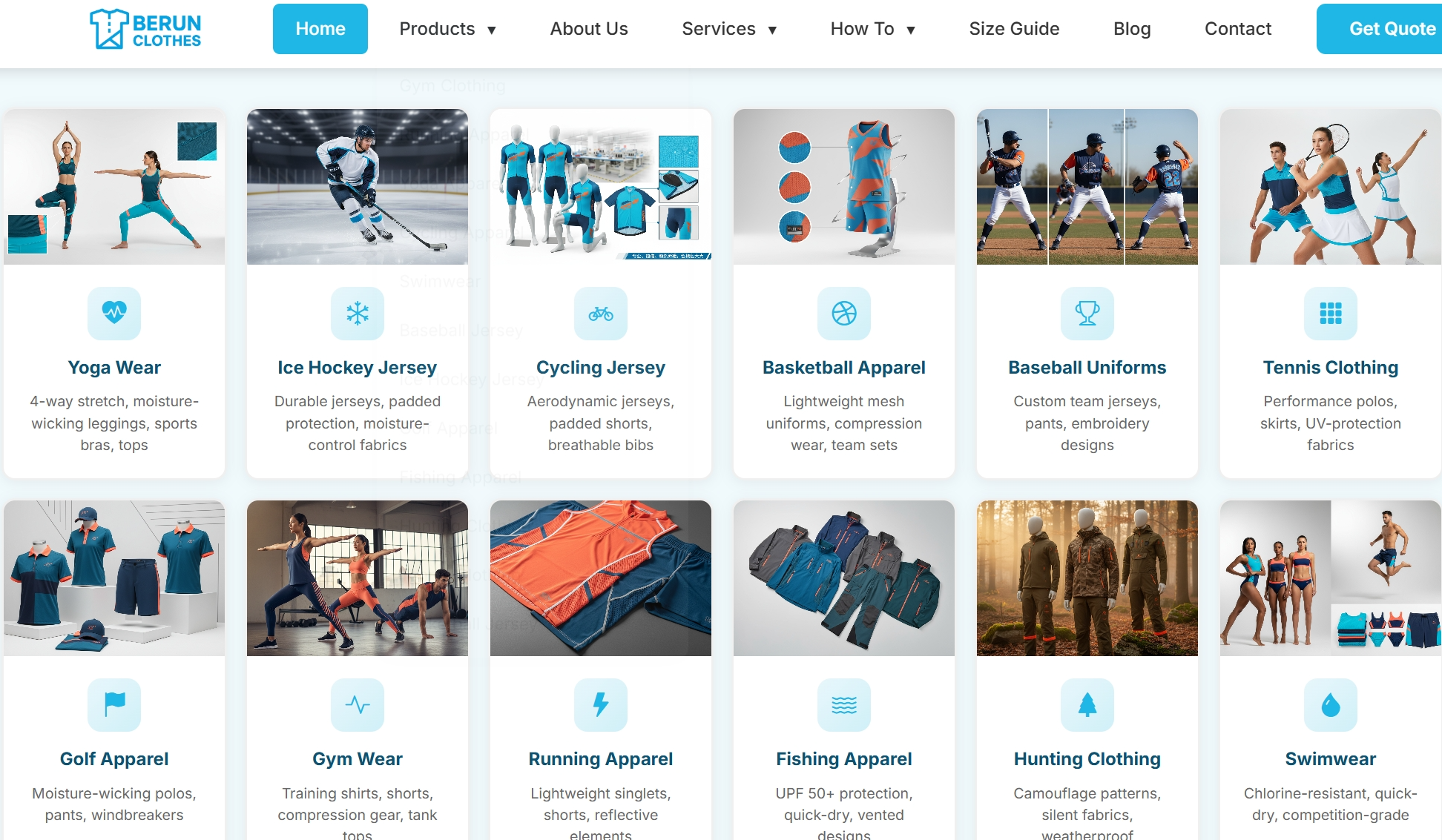

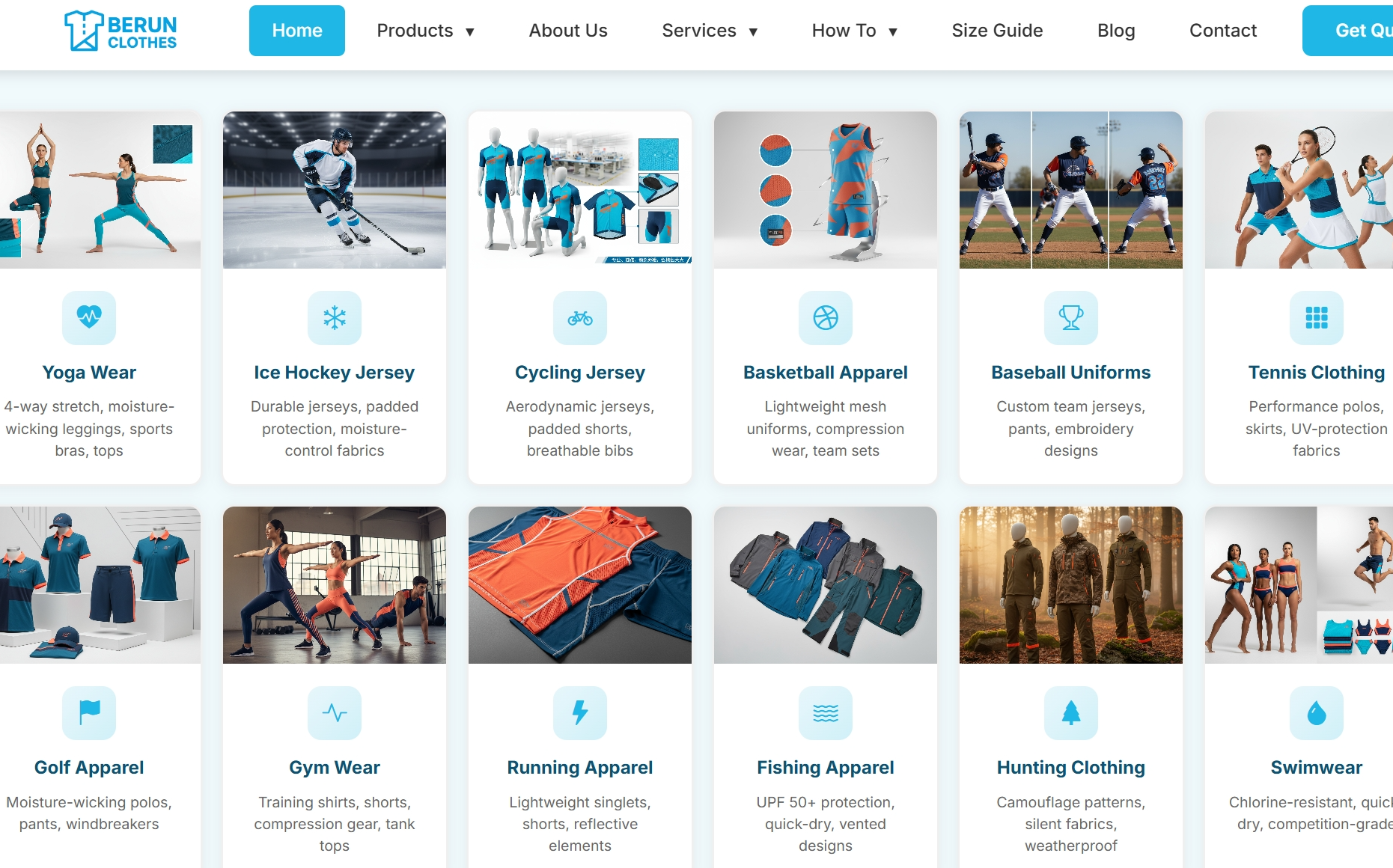

If you are looking for a flexible, high-quality partner, Berunclothes has established itself as a premier private label sportswear expert. Unlike massive conglomerates that treat small orders as an afterthought, Berunclothes specializes in supporting growing brands with unparalleled custom activewear solutions.

With over 15 years of experience, they have evolved from a niche manufacturer into a comprehensive private label activewear manufacturer. They don't just assemble garments; they offer a "one-stop" solution that includes fabric sourcing, pattern making, private labeling, and global logistics. This approach makes them ideal for startups and established brands alike who need reliable OEM/ODM services without the bureaucracy of larger factories.

Tailored for Your Brand Growth

What makes Berunclothes unique among custom sportswear providers is their flexibility. They understand the risks of launching new collections. That's why they offer supportive Minimum Order Quantities (MOQs), often as low as 50 to 100 pieces per style. This allows you to test the market with custom activewear designs without committing to thousands of units upfront.

Their product range is vast, covering everything from high-compression yoga leggings and sports bras to technical running gear and streetwear-inspired tracksuits. As a versatile fitness clothing manufacturer, they utilize performance fabrics that are breathable, moisture-wicking, and durable. They also offer sustainable options, including recycled nylon and polyester, catering to the growing demand for eco-friendly active wear manufacturers.

The Customization Advantage

Speed matters in fashion. Berunclothes offers rapid sample development, typically turning around custom sportswear prototypes in just 7 days. Their bulk production timeline is equally impressive, often completing orders within 20-25 days.

Their customization capabilities are deep. Whether you need sublimation printing, silicone logos, embroidery, or custom hang tags, they handle it all in-house. This level of detail ensures your private label sportswear looks distinctly yours, helping you build strong brand identity in a crowded market.

Ready to Launch Your Sportswear Brand?

Partner with BeRun Sports for low MOQ custom manufacturing, fast samples, and premium quality.

Get Your Free QuoteShahi Exports (India)

India's largest apparel exporter operates on a massive scale. Shahi Exports produces 48.4 million garments every year. That's 132,000 pieces daily. They don't chase volume just to hit numbers; they have built a complete system favored by global brands seeking top-tier athletic clothing manufacturers.

INR 100.12 billion in revenue (about USD 1.2 billion) for FY25 tells the story of their dominance. While post-pandemic chaos hit competitors hard, Shahi kept growing. They own 50+ cut-to-pack factories and 3 processing mills across 8 Indian states. Their new Odisha facility alone makes 300,000 dresses per month.

Vertical Integration That Works

Here's what sets Shahi apart from other activewear clothing manufacturers: 80%+ in-house fabric production. They control cotton and rayon and are expanding into polyesters. Fabric makes up 50% of each garment's cost. By owning the fabric source, they own the margin, eliminating wait times for external mills. Their latest move, Shahi Knits Pvt Ltd, creates a dedicated dyeing ecosystem, ensuring they remain a preferred partner for brands needing reliable OEM/ODM services.

PT Kahatex (Indonesia)

Indonesia's textile giant covers 155 hectares in West Java. PT Kahatex runs one of Southeast Asia's most complete production lines, handling the full chain: polyester chips, fibers, yarn, fabric, garments, socks, and gloves. This vertical capability makes them a powerhouse among activewear manufacturers.

The numbers show their scale. Their Rancaekek facility produces 391,423 tonnes of textiles each year. They began as a small knitting mill in 1979 and now export 100% of their garments to the USA, Japan, and Europe. They are a prime example of high-volume athletic clothing manufacturers.

Energy Efficiency & Net-Zero Goals

PT Kahatex backs up green talk with results. Their Resource Efficient and Cleaner Production (RECP) program saved $8.8 million per year by slashing electricity and water use. They joined the Science Based Targets initiative (SBTi), aiming for Net-Zero by 2050. For brands looking for a sustainable fitness clothing manufacturer with massive capacity, Kahatex is a top contender.

Hongyu Apparel (China)

Dongguan's Hongyu Apparel built a smart business model around flexibility. With an MOQ of just 50 pieces per style, they are a go-to for startups needing custom activewear. Most Chinese manufacturers ask for double that, but Hongyu understands the needs of modern boutique brands.

They've been at it since 2003, making streetwear and casual sportswear. Their 1,800 sqm facility runs 3 production lines with an output of up to 50,000 pieces monthly. They bridge the gap between high-end fashion and functional gear, positioning themselves as unique activewear clothing manufacturers.

The Product Range That Sells

Look at their bestsellers: Custom cotton tees, vintage sports jerseys, and mesh boxy tees. Their pricing hits the sweet spot, with oversized vintage hoodies running $14.99-$23.99. This mid-tier pricing works perfectly for wholesale buyers and direct-to-consumer brands looking for a private label sportswear partner.

Everich Textile (China)

Everich Textile leads China's sportswear manufacturing through fresh ideas. Founded in the 2000s, they now run a full-service sportswear manufacturing hub. If you need a partner with deep technical knowledge, Everich is among the most innovative athletic clothing manufacturers available.

Technical Fabric Innovation

Everich put major resources into moisture-wicking polyester blends and four-way stretch fabrics. Their R&D team created special treatments that boost durability by 40% over standard materials. With a fabric center testing 500+ material combinations each year, they ensure your custom sportswear performs under pressure. Their defect rate stays below 1%, a metric that quality-focused brands appreciate.

Sample development: 5-7 days. Bulk production: 25-30 days. That timeline beats most competitors. Their digital pattern-making system cuts development time in half, proving they are a fitness clothing manufacturer built for speed.

Taian BOWINS Garment Co., Ltd. (China/Cambodia)

120 million sets in 18 years. This Chinese manufacturer has mastered functional outdoor gear. Taian BOWINS is the serious choice for brands needing high-performance gear, distinguishing them from standard active wear manufacturers.

Their specialty list includes hunting gear, ski jackets, heated vests, and tactical clothing. With production bases in both China and Cambodia, they offer 10-15% duty savings for exports to Western markets. This dual-country setup is a massive advantage for clients seeking cost-effective OEM/ODM services.

R&D That Shows Results

BOWINS put $5 million into R&D, resulting in 20% better garment durability. Their heated jacket batteries last 8-10 hours, and their Gore-Tex jackets hit extreme waterproof ratings. They prove that Chinese activewear manufacturers can compete on technical innovation, not just price.

Youngone (South Korea)

South Korea's Youngone Corporation operates on a scale most can't match. 3.52 trillion KRW in annual revenue (about $2.64 billion USD). They are the heavyweights among athletic clothing manufacturers. Started in 1974, they now run 40+ manufacturing facilities across 7 countries.

They make outdoor apparel, sportswear, workwear, and footwear for clients like The North Face, Columbia, and Patagonia. Their widespread production—from Bangladesh to El Salvador—cuts risk and improves delivery times. For big players needing a stable activewear clothing manufacturer, Youngone is the gold standard.

Need a Reliable OEM/ODM Partner?

BeRun Sports offers flexible MOQ, 7-day samples, and end-to-end manufacturing solutions.

Talk to Our TeamRuiteng Garment (China)

Dongguan's Ruiteng Garment hit USD 20 million in 2024 revenue. They excel at one thing: speed without compromise. Their promise of samples in 5-7 days makes them a favorite for fast-moving brands needing custom sportswear.

Real brands in Australia, USA, and Europe trust them. 600+ workers handle everything from gym wear to yoga pants. Their OEM/ODM services cover the full range of production, ensuring that quality control runs from order to final shipment. With low barriers to entry and high standards, they are a practical private label activewear manufacturer for growing businesses.

Hingto International (Australia/China)

Hingto International has carved out a unique niche by focusing heavily on the entrepreneurial side of the industry. They market themselves not just as a factory, but as a launchpad for startups looking for a private label activewear manufacturer. Unlike traditional factories that ghost small inquiries, Hingto thrives on helping new brands launch.

With offices in Sydney and production in Guangzhou, they bridge the gap between Western service standards and Chinese manufacturing prices. They stick to a low MOQ model (often around 300 pieces), making them accessible active wear manufacturers. They specialize in custom activewear ranging from sublimation prints to technical compression gear. If you are an influencer or a gym owner launching a line, Hingto's approachable OEM/ODM services and marketing support make them a standout choice.

Conclusion

The global sportswear manufacturing scene shows an interesting mix. You've got specialized giants like Crystal International and rising stars like Berunclothes changing the game. These athletic clothing manufacturers prove that success isn't just about size; it's about adapting fast and getting what customers want.

What stands out? Big names like Youngone lead with massive power, but agile partners are winning by solving specific problems. Whether you need a private label activewear manufacturer for a boutique collection or a high-volume partner for global retail, the options are vast. The smartest move? Stop chasing the "biggest" option. Find the activewear clothing manufacturers that fit your quality standards and growth plans.

Ready to find your ideal manufacturing partner? Look for those who offer transparent OEM/ODM services and verify their sustainability credentials. The right partner does more than make products; they strictly control the quality of your custom activewear to boost your brand story.