Your old cotton t-shirt feels like a soaking wet towel halfway through your morning run. Meanwhile, your friend breezes by looking fresh in their technical gear. The difference isn't just marketing hype—it's science.

The fabric touching your skin during a run can make or break your performance. It affects your core temperature. It impacts chafing levels. It even changes how motivated you feel to lace up tomorrow.

You might be a 5K beginner dealing with uncomfortable sweat patches. Or a marathon trainer fighting mid-run friction burns. Either way, moisture management fabric and sweat wicking technology transform running from a sweaty struggle into a comfortable rhythm.

This guide cuts through the confusing fabric jargon. You'll learn which materials work (and why cotton fails). You'll discover how to match fabrics to your specific running conditions. Plus, you'll know what to look for in gear that performs as hard as you do.

Why Fabric Choice Matters for Running Performance

Every mile you log subjects your body to an intense thermal battle. Your muscles generate heat. Sweat pools on your skin. The wrong fabric traps that moisture against your body like a wet blanket. Your core temperature spikes by several degrees.

Quick-dry material and synthetic running fabric solve this through physics, not magic. These textiles pull moisture away from your skin up to 5 times faster than natural fibers. Your body stays cooler. Your energy reserves last longer.

The benefits go beyond temperature control. Anti-chafing material with four-way stretch fabric moves with your stride. No more raw skin at mile 8. No more blisters that sideline your training.

Mesh fabric ventilation placed at heat zones—your back, underarms, chest—creates airflow channels. These channels dump excess heat. Think of it as your personal cooling system. Motion activates it.

Proper fabric selection isn't about comfort alone. You need to maintain ideal body temperature. You need to prevent friction injuries. You need to extend your endurance. The right lightweight running material becomes invisible during your run. The wrong choice becomes all you can think about.

Key Performance Features Running Fabric Needs

Running fabric isn't just cloth—it's a performance tool. Clear benchmarks separate functional gear from closet clutter.

Moisture Management: The Foundation

Key Insight: Lower moisture absorption = faster moisture transfer from skin

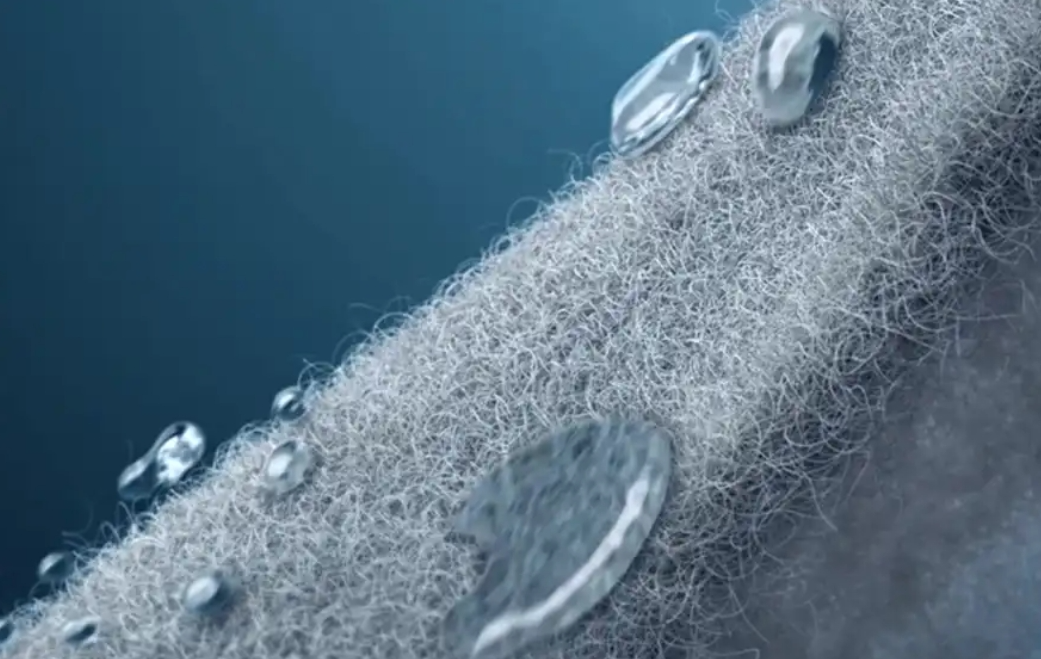

Sweat wicking technology works through a process called moisture regain. Polyester absorbs 0.4–0.8% of its weight in water. Nylon hits 3–5% . Compare that to merino wool at 14–18% . Lower numbers mean faster moisture transfer from your skin.

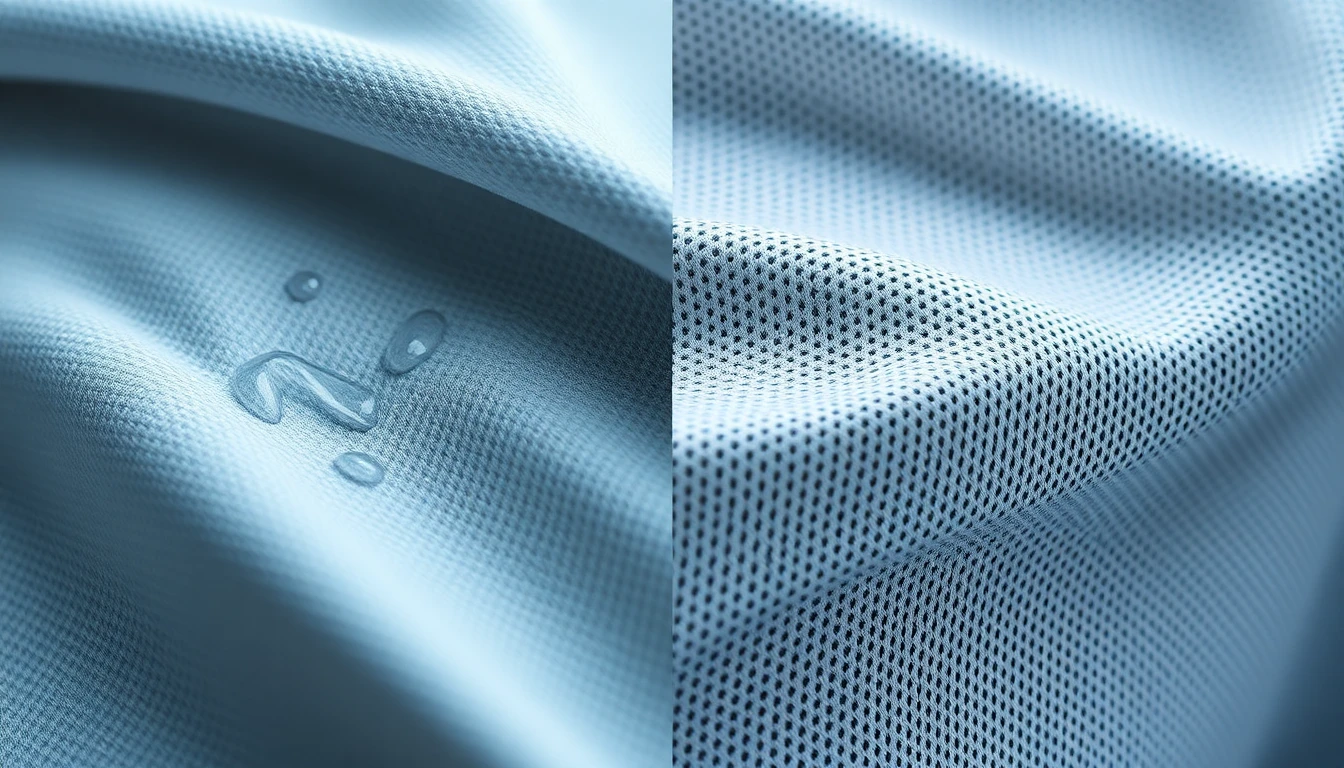

Lab tests measure this. The AATCC 195 vertical wicking test checks how fast high-performance knits pull moisture. They need to pull it over 100 mm in 30 minutes . Premium running shirts use double-layer construction. A water-resistant inner surface pushes sweat outward. The outer layer absorbs it.

Quick-dry material hits another mark. It dries to 5% moisture left in under 20–30 minutes at room conditions. That's the difference between a damp shirt at mile 3 and staying dry through your entire workout.

Breathability Metrics That Matter

Mesh fabric ventilation isn't random. Engineers measure breathability using ISO 11092 standards. They track evaporative resistance (Ret). Hard running needs Ret values below 6 m²Pa/W . Moderate activity works with 6–13 m²Pa/W .

High-performance summer shirts achieve water vapor rates over 8,000–10,000 g/m²/24h . Strategic mesh panels go in high-sweat zones—back, chest, underarms. They create 10–25% open area where your body dumps the most heat.

Stretch, Recovery, and Compression

Four-way stretch fabric needs 8–20% elastane blended into knit structures. Quality running jerseys extend 120–150% under minimal load. They recover 90–95% of their original width within two minutes.

Compression fabric running gear targets specific pressure zones. Look for 10–25 mmHg at calf and thigh muscles. This isn't about elastane percentage alone. It's built through pattern design and fabric calculations.

Weight and Abrasion Standards

Lightweight running material hits precise GSM (grams per square meter) targets. Hot-weather tops weigh 90–130 g/m² . tights run 180–250 g/m² . Thickness stays between 0.3–0.7 mm . This keeps the fabric opaque.

Durability matters for long-term value. Premium synthetic running fabric survives over 20,000–30,000 Martindale abrasion cycles before showing wear. Seams hold 150–250 N of force at stress points.

Anti-Chafe Design

Anti-chafing material achieves a friction level below 0.4–0.5 (static) and 0.35–0.45 (dynamic) against skin. Flatlock seams measure under 1.5–2.0 mm thick . They have 8–12 stitches per inch .

Smart seam placement avoids friction spots. Think medial thighs, nipple lines, underarms, and heel-Achilles contact zones. These details prevent the raw skin that derails training plans.

Polyester: The Most Popular Running Fabric

Polyester dominates the running apparel market. This synthetic fabric claims 60% of the global sportswear fabric market in 2025 . Walk into any running specialty store. You'll find polyester in most technical shirts, shorts, and tights on the rack.

The numbers prove its dominance. Polyester fiber production hit 57% of total global fiber output in 2023—124 million tonnes. That's more than all other fibers combined. The polyester performance fabric market reached USD 28.6 billion in 2024 . Analysts project it'll grow to USD 41 billion by 2033 at a 4.2% annual growth rate .

Why does polyester beat the competition? Three key traits.

Durability wins the long game. Your polyester running shirt survives hundreds of wash cycles. It holds shape after sweaty 10-milers and brutal trail runs. Cotton pills and stretches out. Polyester bounces back.

Moisture management beats natural fibers. Polyester absorbs 0.4–0.8% of its weight in water . Cotton soaks up 7–10%. Your polyester shirt pulls sweat off your skin. It pushes moisture to the outer layer where it evaporates. You stay dry. Your body temperature stays stable.

Cost makes performance accessible. Mass production keeps polyester affordable. You get technical performance without premium prices. Brands blend polyester with spandex for stretch and compression properties . Gear moves with you, supports muscles, and costs less than specialty fabrics.

The Microfiber Revolution in Running

Polyester microfiber fabric changed lightweight running gear forever. This market segment reached USD 739.7 million in 2025 . It's growing to USD 1.03 billion by 2035 . Apparel grabs 35% of this market . Running and activewear demand drives most of this growth.

Microfiber polyester weighs 90–130 g/m² for summer running tops. That's feather-light. Yet it maintains opacity and structure. The fine fibers create more surface area for moisture transfer. Air gaps between fibers boost breathability. Your shirt feels like nothing during mile repeats.

Sustainability Meets Performance

Recycled polyester solves the environmental problem without hurting performance. Major brands like Adidas and Columbia Sportswear now build running lines around recycled content. The fabric performs the same as virgin polyester. It wicks moisture. It resists abrasion. It dries fast.

Manufacturers convert plastic bottles and old polyester into new running fabric. This approach cuts petroleum use. It reduces landfill waste. You get the same anti-chafing material and lightweight running material benefits with a smaller carbon footprint.

Why Runners Choose Polyester Over Alternatives

Nylon and merino wool compete for market share. Cotton still shows up in casual athletic wear. Polyester keeps its lead through practical benefits.

Price-to-performance ratio : Polyester gives you pro-grade moisture management at a friendly budget. A quality polyester running shirt costs $30–50. Merino runs $80–120.

Wash-and-wear ease : Throw polyester in the washing machine. Tumble dry on low. No special care needed. It comes out ready for tomorrow's run. Merino requires delicate cycles and air drying.

Works in all conditions : Polyester handles humid Florida summers and dry Colorado winters. Blend it with different weights and weaves. You get year-round performance from one fabric type.

The Asia Pacific region produces most performance polyester fabric. Manufacturing hubs in China, Vietnam, and Bangladesh make fabric for global running brands. This setup drives competitive pricing and rapid innovation in fabric technology.

Polyester running clothes aren't going anywhere. The fabric keeps getting better with improved recycling methods, better breathability structures, and smarter moisture management systems. Your next PR might just depend on those synthetic fibers working harder than you do.

Nylon: Durability Meets Comfort

Nylon builds running gear that refuses to quit. This synthetic fiber delivers 6.8–6.9 g/denier tensile strength . That's the muscle behind training shorts that survive years of trail abuse and wash after wash.

The engineering tells the story. Nylon 6,6 filament yarns woven in 2/2 twill patterns create fabric that flexes without breaking down. Two picks of textured nylon in the weft direction boost tear resistance. This beats what polyester can do. Your running tights stretch over your quads. They recover their shape. You won't see that saggy-knee look after three months.

Premium nylon running fabric uses 1.0–3.0 denier per filament in performance blends. Finer deniers mean softer feel against skin. Heavier 500D nylon appears in high-wear zones. Think inner thighs, seat panels, knee reinforcements. The denier number connects to durability. Higher numbers mean tougher fabric that handles friction.

The Comfort Edge Over Polyester

Nylon absorbs 3–5% of its weight in water . Polyester only absorbs 0.4–0.8%. That sounds backwards for moisture management fabric , right? Wrong. This slight moisture uptake creates a softer, more natural feel during runs. The fabric doesn't feel clammy or synthetic against sweaty skin.

Four-way stretch fabric made with nylon delivers superior recovery. The fibers snap back to original shape 90–95% within two minutes after stretching 120–150%. Your compression tights maintain consistent pressure mile after mile. No loosening around the calves by your final loop.

Anti-chafing material gets better with nylon's natural slickness. The fiber surface shows friction coefficients of 0.35–0.42 against skin . That's lower than polyester's rougher texture. Less friction means fewer hot spots on long runs. Your inner thighs thank you at mile 15.

Where Nylon Wins the Performance Battle

NYCO blend ratios (nylon-cotton mixes) hit 50:50 to 80:20 in breathable running jackets and weather-resistant gear. The nylon part adds abrasion resistance. Cotton brings moisture absorption for comfort. Together they create lightweight running material that breathes better than pure synthetics. Plus, you get the same durability.

Tear strength gets a 47% boost with nylon 6,6 filaments woven into the fabric structure. Compare lightweight and heavyweight versions with 2-pick weft textured nylon. Both resist the catches and snags that destroy cheaper running gear on brambles or rough pavement.

The trade-off? Nylon costs more than polyester. A quality nylon running shirt runs $60–90 versus polyester's $30–50. You're paying for longevity. That nylon shirt survives 20,000–30,000 Martindale abrasion cycles . Performance specs stay intact. It's an investment in gear that doesn't quit as your training gets serious.

Merino Wool: Natural Temperature Regulation

Merino wool uses physics your polyester shirt can't copy. This natural fiber balances temperature in ways synthetic materials just don't get.

Climate-chamber tests with real people show the difference. Polyester, cotton, viscose, and wool all work the same while you're running. Your body makes heat. You sweat. No problem. Stop moving, and wool wins. It keeps you comfortable during exercise and after. Other fabrics make you feel clammy or cold.

The Science Behind Wool's Temperature Control

Merino's fiber structure gives it an edge. The outside repels water. The inside attracts water. This two-layer setup soaks up 33% of its weight in moisture vapor without feeling wet on your skin.

Here's the cool part. Merino absorbs moisture and releases heat. Scientists call this "heat of sorption." The heat release order: wool > cotton > polyester . After a hard run, wool builds a warmer layer between fabric and skin. You skip that post-run chill that sends you running for a jacket.

Dynamic Breathability in Real Conditions

Lab tests don't show what happens on actual runs. Researchers built a new way to measure: "dynamic breathability" —how fabric performs as humidity, temperature, and body heat shift.

Wool wins here. Humidity rises from 45% to 80% during your run? Wool keeps you comfortable. Polyester, cotton, and viscose can't match it. The air next to your skin stays more stable with wool. Your body uses less energy to control temperature.

Tests used clothes of the same weight and thickness. The fiber type was the difference. Wool created lower humidity next to skin and warmer surface temperatures during recovery than polyester. People rated wool more comfortable while drying.

Where Merino Wins Your Training

Activities with starts and stops show wool's power. Trail running with big climbs. Interval training. Long hikes with many breaks. 100% merino wool mid-layers beat cotton, viscose, and polyester in back-and-forth activity and rest cycles.

The fiber keeps going after you stop. Wool clothes showed better temperature control after exercise than any synthetic in tests. They held warmth better. They cut down that bad cool-down time you get with sweat-soaked synthetics.

Tests went beyond exercise to sleep. At 17°C room temperature , wool sleepwear gave faster sleep onset than cotton. People fell asleep quicker. They got more N3 deep sleep (20.1% versus 19.6% of total sleep time). Wool next to skin changed core body temperature in ways that boosted sleep quality.

The moisture absorption—that 30–33% of dry weight —handles the humidity spikes your body makes. Heat of sorption adds warmth right when you need it. This isn't a sales pitch. It's physics you can measure, working for your comfort.

Bamboo Fabric: Eco-Friendly Softness

Bamboo fabric solves a running gear problem most people don't discuss. You want technical performance. But you're tired of wearing petroleum-based plastics next to your skin.

This natural textile delivers moisture management fabric performance. It just takes a different path than synthetics. Bamboo fibers wick sweat well. They dry fast. The difference? How they feel and what happens after your run.

The Softness Factor That Changes Your Mind

Bamboo fabric feels softer than cotton right out of the package. That silky-smooth texture gets better with every wash. Your running shirt becomes your favorite shirt. Not just for miles, but for recovery days on the couch.

The fiber structure creates this luxury feel. Round bamboo fibers resist fraying and roughness. Synthetic fabrics develop these issues after months of training. Siro Compact spinning tech reduces pilling. Your gear keeps that smooth touch through hundreds of wash cycles.

Natural Performance Features Built In

Bamboo's "kun" compound gives you germ protection. No chemical treatments needed. Your running clothes resist the bacteria that creates stink. Post-run odor control happens on its own. This helps during multi-day training blocks. Laundry piles up.

UV protection comes from lignin and ionic properties in the fiber. Temperature control works through lightweight cellulose structure. The fabric cools you down in summer heat. It provides warmth during autumn morning runs. Thermal regulation adapts to your body's needs.

The Sustainability Story With Numbers

Bamboo grows without pesticides, fertilizers, or herbicides. It needs far less water than cotton. No replanting needed. Bamboo regrows from its root system. Plus, it captures CO2.

Closed-loop processing captures 99.5% of chemicals for recycling. The fabric breaks down to natural compounds at end of life. Oeko-Tex® Standard 100, GOTS, and GRS verify these green claims.

The bamboo fabric market proves runners care about this. Market value hits $91.40 billion by 2030 . Bamboo clothing grows from $2.5 billion in 2023 to $5.2 billion by 2030 . That's 10.7% annual growth .

Performance Blends That Work

100% bamboo fabric excels in base layers and recovery wear. Blend it with organic cotton or recycled fibers. You get running-focused performance. Bamboo-cotton knits make great training shirts. Bamboo-blend wovens create tough running shorts.

Premium options mix bamboo with specialty fibers for targeted benefits. The cost stays fair. More affordable than Tencel or Supima cotton. You get similar quick-dry material performance and better comfort.

Australian bamboo baby clothing saw 15% sales increases in 2022 . Parents chose it for skin-friendliness and green benefits. Runners make the same choice for the same reasons. Bamboo fabric gives you performance without compromise.

Spandex/Elastane Blends: Why Stretch Matters

Running gear without stretch is just expensive cotton. Your body moves through complex patterns with every stride. Hip flexion. Knee extension. Shoulder rotation. Fabric that doesn't move with you fights your natural body mechanics.

Elastane stretches up to 700% of its original length without breaking down. Pull it. Release it. The fiber snaps back to start with 95% recovery rate . This isn't just about comfort. It's about performance that changes how your muscles work during miles.

Four-way stretch fabric moves in two directions—horizontal across the grain and vertical along it. Your running tights need this. A simple forward stride creates pulls across quads, hamstrings, and glutes in multiple directions. Fabric stretches one way? It restricts movement in the other direction. You lose range of motion. Your stride shortens. Energy gets wasted fighting your own clothes.

The blend percentage controls function. 2-4% elastane in a running shirt gives enough flex to prevent binding across shoulders during arm swing. Bump that to 5-10% for moderate stretch . Your training tops move with torso rotation. They don't ride up or bunch.

Compression fabric running gear uses 15-20% elastane for targeted muscle support. This higher percentage keeps consistent pressure— 10-25 mmHg at calf and thigh zones —through the entire run. Fabric with low elastane content loses compression after the first mile. Your muscles don't get the support you paid for.

Stretch calculation matters for fit prediction. Take a 4-inch fabric sample. Stretch it to 6 inches. The math: (6-4)/4 × 100 = 50% stretch . Running tights need 50-75% stretch for comfortable movement. Leggings and compression gear demand 75%+ stretch for second-skin fit without limits.

Fabric weight affects elastane content. Heavier materials stretch less even with the same elastane percentages. A 250 g/m² compression tight with 18% elastane won't stretch as much as a 180 g/m² training tight with the same blend. The weight creates resistance against the elastic fibers.

Bio-based spandex options now deliver performance with less harm to the planet. 17% bio-based elastane blended with 83% recycled polyester creates lightweight baselayers with full stretch recovery. Another blend uses 5% bio-based spandex with modal and recycled polyester for 20% lower carbon footprint . The stretch stays the same. The planet benefits.

Quality elastane stops the bagging and sagging that ruins running gear. Your leggings develop loose knees after three months? Poor recovery rate. Premium blends keep shape through hundreds of wash cycles. The fabric returns to original size. Your compression stays the same. The gear performs like new.

Cotton: Why to Avoid It for Serious Running

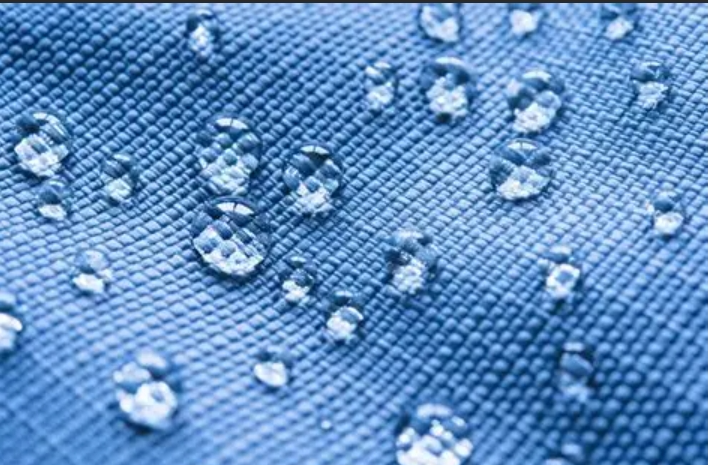

Cotton fails at the one job running fabric must do: move sweat away from your body. The numbers expose the problem. Run for 50 minutes in a cotton shirt. It hits 41% of its maximum sweat absorption capacity . Synthetic fabrics reach just 18% in the same time. Both leave sweat on your skin. Cotton traps it in the fabric. Synthetics push it to the surface where it evaporates.

The fiber structure works against you. Cotton absorbs water fast and holds it inside the fibers. Sweat gets trapped. It doesn't spread across the fabric. Performance synthetics spread at 2.8–4.0 mm/s . Cotton moves far slower. The moisture sits in wet patches instead of spreading thin for fast evaporation.

Drying rates tell the real story. A regular cotton T-shirt needs over 45 minutes to dry after hard exercise. Basic polyester dries in 25 minutes . Advanced synthetics finish in 8–10 minutes . Lab tests show cotton's sweat dry rate at 0.67 mL/h . Performance blends dry faster through better surface transport.

The consequences hit hard during serious training. Your shirt gets heavier as cotton absorbs sweat. That extra weight increases the work of arm swing. Wetness raises friction. Chafing starts at mile 8. Poor spread creates large wet zones that stick to your skin. Your body can't control temperature well. The cold-wet feeling after you finish your intervals? That's cotton holding moisture against your core. Synthetics would have dried already.

Choosing Fabrics by Weather Conditions

Temperature and humidity decide how your fabric performs. Brand names and price tags matter less. Phoenix heat puts different demands on your body than Portland drizzle. Summer 5K fabrics won't cut it for winter marathon training.

Hot, dry climates (≥30–35°C, low humidity) need maximum airflow. Go lightweight. Tops should weigh 80–150 g/m² . Shorts need 120–180 g/m² . This weight range gives you the cooling you need. Mesh fabric ventilation panels across your back and chest release heat fast. Look for loose weaves in technical polyester running clothes . These allow air to move through. Light colors reflect sun rays. Dark colors soak them into the fabric.

Hot, humid conditions (≥28°C, humidity ≥70%) ? Breathability alone won't help. You need strong moisture management fabric that pulls sweat off your skin right away. Sweat wicking technology in polyester or microfiber moves moisture to the outer surface. Knit builds with open mesh zones work better than dense weaves. Your body makes sweat faster than dry air can dry it. The fabric has to move that moisture away from your core.

Moderate temperatures (20–28°C) offer flexibility. Blend fabrics give you comfort and performance. Polyester-cotton or modal blends at 120–200 g/m² for shirts handle changing humidity. Easy runs? More natural fiber feels better. Tempo workouts and intervals? Increase polyester to ≥50% for better quick dry material results.

Cool weather (10–20°C) calls for layers. Your base layer should be lightweight running material at 150–200 g/m². This handles sweat and gives light warmth. Synthetic running fabric or merino wool fits here. Add a mid-layer once temps drop below 15°C. Wind affects you more than cold does. A four-way stretch fabric windbreaker over your base layer stops heat loss. It does this without extra bulk.

Cold conditions (≤10°C) need wool. Merino base layers at 200–260 g/m² give natural warmth plus sweat control. The fiber holds warm air between you and the fabric. It moves sweat without feeling wet. Add a thick fleece mid-layer at freezing temps. Your outer shell needs wind protection. Lightweight running material in tight-woven nylon or polyester blocks wind. It also lets moisture escape.

Rain changes everything. Cotton works against you. Wet cotton steals heat from your body 25 times faster than dry fabric. Polyester running clothes shake off water and dry fast. Nylon shells with DWR (durable water repellent) finish handle light rain. Heavy rain needs sealed layers over polyester or nylon. Keep synthetic or wool base layers against your skin. These hold less water and keep you warm even when wet.

Wind needs tight weaves. Loose fabrics let cold air steal your body heat. Dense synthetic running fabric in your outer layer blocks wind. Put wool or fleece under it for warmth. This combo stops cold air and handles sweat from hard runs.

Match fabric to conditions. This affects your comfort and how you perform.

Selecting Fabrics by Running Distance and Intensity

Your fabric needs change as you shift from easy miles to race pace. A 5K sprint needs different fabric engineering than a marathon grind. How hard and long you run determines which fabric properties matter most.

High-intensity efforts (≥75–80% VO₂max) — intervals, tempo runs, races — need pure synthetic performance. Your body dumps heat fast. Sweat production spikes. Polyester running clothes and nylon blends handle this through strong moisture transport. Look for fabrics hitting ≥6–7 mm/s spreading speed and large positive one-way transport values (>200) . These numbers mean sweat moves from skin to fabric surface right away. You stay dry when it counts.

Race data backs this up. Athletes running a 20-km time trial in 60% polyester/40% nylon blend finished 0.8% faster than cotton-wearing competitors. That's 15.7 seconds saved. The final 6 km showed the real gap: 0.98 km/h faster speed and 18.4 W more power output in synthetic gear. Skin temperature dropped 1°C with proper moisture management fabric . Comfort ratings improved across the board.

Short, explosive runs (≤5 km, under 30 minutes) work best in ultralight synthetics weighing ≤130 g/m² . You need top wetting time ≤5 seconds and bottom surface ≤10 seconds . The fabric pulls sweat right away. It dries before you notice wetness. Minimal elastane keeps the shirt from shifting during hard arm drive.

Middle distance (5–15 km, 30–90 minutes) balances wicking with air flow. Target 120–150 g/m² weight and ≥3–4 mm/s spreading speed . Mesh fabric ventilation zones dump heat during sustained efforts. Anti-chafing material matters a lot here. Friction coefficients need to stay ≤0.10–0.15 at high-contact zones. Otherwise, mile 8 brings raw skin and shortened strides.

Marathon and ultra distances (≥90 minutes) need fabrics built for friction control and sustained transport. Choose synthetic running fabric with μ ≤0.10 surface friction and smooth texture. High one-way transport capability keeps sweat moving outward through hour three and beyond. Skip cotton content. Even blends fail as sweat volume beats absorption rates. Cotton's 0.67 mL/h drying rate creates wet patches that rub and chill. Synthetics with ≥0.9 mL/h dry rates keep working as miles pile up.

Low-intensity recovery runs (≤70% VO₂max) give you more fabric options in cool, dry conditions. Cotton blends won't destroy your comfort on a short, easy jog. But synthetics still win for anything over 30 minutes. The performance gap grows with duration and sweat volume.

Match fabric specs to your workout intensity. Your PR depends on it.

How to Identify High-Quality Running Fabric

Labels lie. Marketing teams slap "performance" on anything with a logo. You need hard numbers to separate gear that performs from gear that disappoints.

Start with GSM (grams per square meter) —the fabric weight metric that predicts breathability. Cut a 10x10cm sample from the shirt you're eyeing. Weigh it in grams. Times 100. Target 180–200 GSM for summer running tops. This range gives you airflow without transparency. Midweight fabrics run 210–250 GSM . They add durability but sacrifice cooling. Heavy denim hits 300+ GSM . Skip it for running—it's stiff and traps sweat.

Shrinkage testing reveals fit stability. Wash your sample following care instructions. Measure size change. Quality synthetic running fabric shrinks less than 5% . Cheap material contracts 8–10%. Your fitted shirt becomes a belly-exposing crop top after three washes.

Colorfastness ratings prevent dye disasters. The AATCC Gray Scale measures color hold. Premium running gear scores minimum 4.0 for washing resistance (AATCC 61), light exposure (AATCC 16), and crocking—rubbing transfer (AATCC 8). Sweat speeds up fading. Fabrics below 4.0 leave color on your skin. They lose brightness fast.

Strength tests show durability under stress. Tear strength needs over 20 lbs per ASTM standards. Tensile strength should exceed 50 lbs . Nylon beats polyester here—note that 6.8–6.9 g/denier advantage. Weak fabric splits at seams during intense training.

The 4-point inspection system catches production defects. Check fabric rolls before cutting. Assign points: 1 point for defects under 3 inches, 2 points for 3–6 inches, 3 points for 6–12 inches, 4 points for anything larger. Maximum 40 points per 100 square yards passes inspection. Weave flaws, stains, and odd spots add up. Reject fabric that exceeds limits.

pH levels between 4.0–7.5 keep fabric skin-safe. Extreme pH causes irritation during long runs. Test with pH strips. Fabrics outside this range trigger rashes and discomfort.

Elasticity tests confirm four-way stretch fabric quality. Pull a 10cm sample. It should extend 20–50% and recover in 2 seconds. Release it. Watch for 95% snap-back . Quality spandex blends—like 80% nylon/20% elastane —return to original size. Fabric that stays stretched loses compression fabric running benefits mile after mile.

Pilling resistance keeps texture smooth. The Martindale abrasion test rates fabric on a 5-point scale. Demand rating 4 or higher . Premium lightweight running material survives over 10,000 cycles without fuzzing. Cheap polyester pills after 3,000 cycles. Those fabric balls create friction and ruin appearance.

Dimensional stability testing (AATCC TM179) measures post-wash changes. Quality running fabric changes less than 3% in length and width. Your gear keeps its fit through hundreds of washes.

Third-party labs like SGS and Intertek certify these benchmarks. Look for test reports showing under 4% shrinkage , GSM variance below 5% , and tensile strength above 45 lbs . Yarn specs matter too. Tenacity over 4 g/denier and count Ne 40–60 create fine, strong weaves in top-tier polyester running clothes .

Run these tests before buying in bulk. Touch and marketing copy can't replace hard data. The numbers separate quick dry material that works from fabric that just looks technical.

BeRunClothes.com Fabric Technology and Product Recommendations

Berunclothes.com builds custom sportswear with 30 years of OEM experience . We choose fabrics based on lab-tested performance—not marketing talk.

Quick-Dry Polyester: The Foundation

Our core fabric line uses 180-220 GSM quick-dry polyester . This weight gives you breathability without being see-through. Special channels in the fabric pull sweat away from your skin. The weave resists wear and tear through 20,000+ Martindale cycles . Colors stay bright even after hundreds of washes.

Custom Performance Options

Baseball jerseys and base layers use performance polyester for compression fit. The fabric keeps steady pressure during fast moves—batting, pitching, running bases.

Gym and sports apparel adds anti-odor treatments to the moisture-wicking base. You can choose compression levels from light support (10-15 mmHg) to firm compression (20-25 mmHg) . Removable padding lets you adjust protection where you need it.

Running gear fabrics combine three proven technologies: moisture-wicking channels, quick-dry build, and germ-fighting treatments. The germ-fighting finish stops bacteria that cause odor during long training sessions.

Why Choose BeRunClothes.com

We've been making athletic wear for three decades. This gives us a fabric selection edge. Our team knows which fabric weights work for different sports. Compression calculations? We've got them down. We test how fast fabrics wick moisture right here in our facility. You get synthetic running fabric built for your specific athletic needs—not off-the-shelf options.

Conclusion

The right fabric changes your running. No more sweaty struggles—just smooth motion. Moisture-wicking technology and smart fabric choices boost your comfort and performance. They also help prevent injuries. Polyester dries fast. Nylon lasts through marathons. Merino wool handles extreme temperatures. The best fabric for running clothes works with your body, not against it.

Your next run needs better than cotton. Check your usual running conditions first—distance, weather, and intensity. Then pick fabrics that match. Don't guess at quality. Look for four-way stretch. Check how seams are made. Put anti-chafing materials in spots where friction happens most.

Ready for the difference? Browse BeRunClothes.com's performance collection. Each piece uses the fabric tech we've covered. Your feet know the path. Time for your gear to keep up. Run smarter, not just harder.