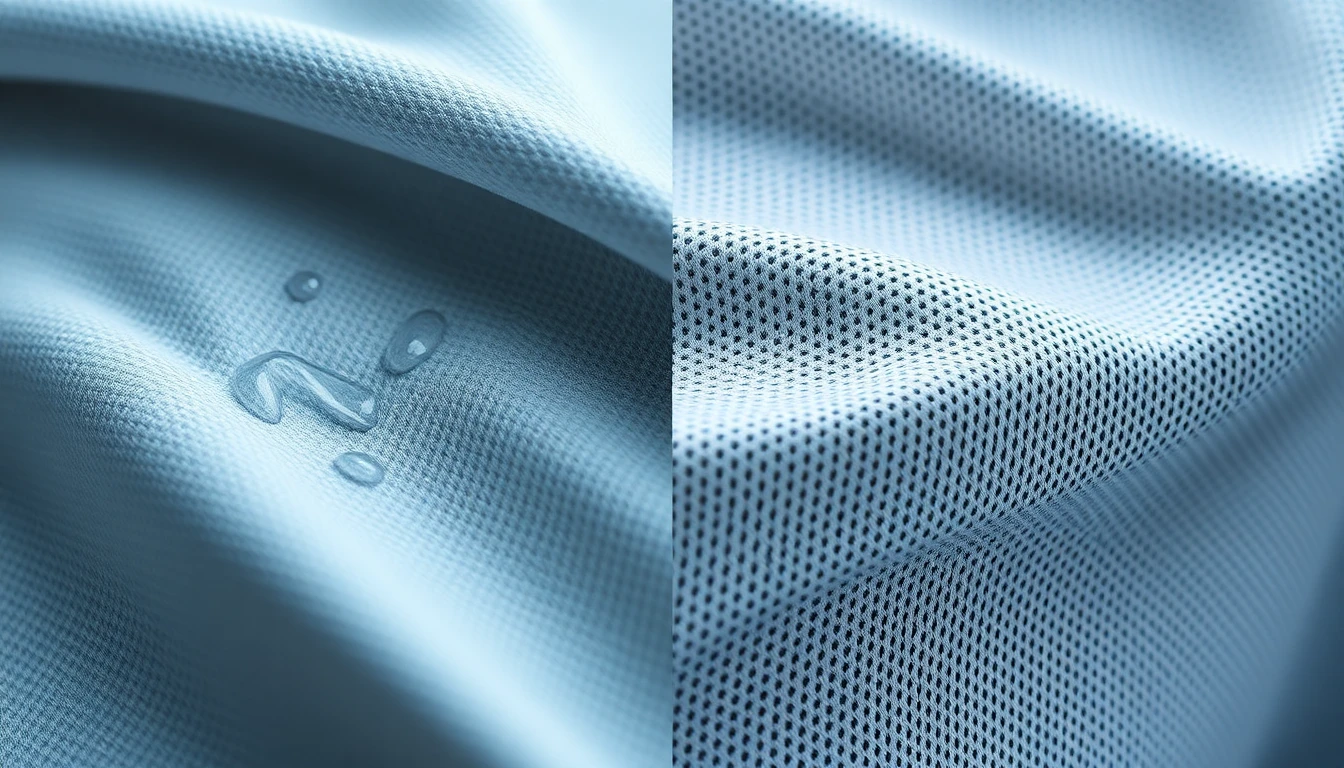

1. Moisture Management (Sweat, Wicking, Drying)

Here's the truth about workout fabrics: the gap between finishing strong and quitting halfway isn't just willpower. It's how well your clothes handle sweat.

You're pushing through that last set or hitting mile five. Your body dumps moisture onto your skin. What happens next? That depends on what you're wearing. Moisture management isn't marketing fluff. It's measurable science. It separates real performance gear from cotton T-shirts that cling like wet towels.

How Fabric Scientists Test Sweat Performance

The industry standard test (AATCC 195, if you care about the technical name) measures what happens to sweat hitting fabric. They track wetting time—how fast a water droplet gets absorbed. This happens on both the skin side and outer surface. They measure absorption rate in millimeters per second. They calculate how far moisture spreads sideways (maximum wetted radius). They also check how fast (spreading speed).

The magic number everyone chases? Overall Moisture Management Capacity (OMMC) scored from 1 to 5. Good performance fabrics hit 0.5 to 0.7. Your average cotton shirt? Not even close.

Polyester Performance

Cotton Performance

The Polyester Advantage in Numbers

Lab tests on various knit structures reveal the stark reality. Take a typical 70:30 polyester-cotton blend with a fleece-style loop knit. The wetting time clocks in at 4.8 seconds on the skin side and 4.2 seconds on the outside. Absorption rate? A modest 0.8 mm/s where your skin touches. This bumps to 1.5 mm/s on the outer layer.

But here's where cotton fails big time: the maximum wetted radius hits just 10-12.2 mm. Sweat sits there in a damp patch instead of spreading out to evaporate. The one-way transport index (how well moisture moves away from your skin) drops to 36.2%. That's terrible.

Switch to rib-knit structures with higher synthetic content. The numbers transform. The wetted radius jumps well beyond 12 mm. The one-way transport index climbs up. Why? Lower fiber density, better porosity, more capillary action. The fabric pulls sweat away from your body. It disperses it across a wider surface area.

Cotton's Fatal Flaw

Add more natural fiber (what researchers call "cattail content"). Performance tanks. More fiber density means fewer air gaps. Less porosity equals worse dispersion. The result? Moisture sits against your skin. It cools you while resting (making you clammy). But it provides zero cooling during your workout.

The Drying Speed Reality

High-performance polyester fabrics dry in 12 to 18 minutes. They do this while keeping air permeability of 700-1200 mm/s and that key 0.5-0.7 OMMC rating. Cotton? You'll still be damp starting your next exercise.

Research models prove that higher synthetic fiber percentage links to better moisture management and air permeability. The equation is simple: more polyester equals faster wicking, better spreading, quicker drying. Cotton absorbs moisture but traps it. This creates a soggy space against your skin. It kills performance and breeds bacteria.

For real athletic performance, polyester doesn't just win. It dominates every measurable metric that matters during sweat.

2. Breathability & Thermal Feel

Cotton feels cooler at first touch. Polyester performs better once you start moving. Athletic fabric science works in surprising ways.

Sports labs use two main measurement systems. Air Permeability tests measure airflow through fabric under set pressure—125 Pa using the ASTM D737 standard. The unit? Cubic feet per minute (CFM) or cm³/s/cm². Higher numbers mean more air movement. Better cooling.

The second metric matters more during hard workouts: Moisture Vapor Transmission Rate (MVTR). This shows how many grams of sweat vapor pass through one square meter of fabric over 24 hours. The numbers tell the story:

The Thermal Resistance Reality

ISO 11092 testing shows the truth about heat management. This standard measures two key factors using a sweating guarded hotplate. Thermal Resistance (Rct) tracks heat loss in m²·K/W units. Lower values mean heat escapes faster.

Water Vapor Resistance (Ret) measured in m²·Pa/W shows real breathability under sweat conditions. The scale is honest:

Cotton gives you that cool sensation at first touch. It's real. GB/T 35263-2017 standards measure this cool feeling coefficient by tracking heat flux at fabric contact points. Cotton absorbs body heat faster on first touch. It feels refreshing for about 30 seconds. Then physics takes over. The absorbed moisture stays there. It blocks airflow. Your body heat builds with no escape.

Performance polyester fabrics skip that first cool touch. They give you something better: steady temperature control through your whole workout.

3. Comfort, Handfeel & Skin Sensitivity

Sports fabric labs don't use vague words like "soft" or "scratchy." They measure how fabric feels against your skin. They use precision tools.

The Fabric Touch Tester (FTT) runs a full comfort profile in five minutes. It measures bending stiffness. This shows how fabric drapes around your body. It checks compression force—that plush or firm feeling you notice. Surface roughness gets tested too. This causes prickle. Friction coefficient shows smooth glide versus skin drag. Thermal conductivity reveals cool touch versus warm touch. The machine gives two key scores: Total Hand and Total Feel. These numbers predict comfort before you try the garment on.

China's FZ/T 01166-2022 standard goes further. It builds math models. These link physical measurements to what your skin feels. Quality control teams use this. It keeps comfort the same across all production batches.

The Skin Contact Reality

The Tactile Sensation Analyzer (TSA) measures what your skin experiences. It tracks four things: softness, smoothness, stiffness, and crinkliness. The key outputs? TS7 (softness index—lower numbers mean softer). Also TS750 (smoothness index—lower values equal less irritation). These combine with fabric weight and thickness. They create the HF (Hand Feel) value. Higher HF scores mean better comfort. In controlled studies, HF values match human preference up to 100%.

Cotton scores higher on initial softness. That natural fiber surface feels gentler at first contact. But modern performance polyester has caught up. Microfiber design and surface treatments made this happen.

The PhabrOmeter pushes fabric through a ring. It measures resistance. The Fmax (maximum force) number tells the story. Higher resistance means stiffer fabric. This feels less comfortable against moving skin. Premium athletic polyester now matches cotton on these friction tests. Sometimes it beats cotton. Plus, it keeps its moisture and durability strengths.

Got sensitive skin? Look past fiber type. Check fabric construction. Look at surface finish. Examine flatlock seams. The engineering matters more than the material.

4. Durability, Shape Retention & Colorfastness

Your workout shirt takes a beating. Gym bags. Locker floors. Sweat sessions every week. Multiple washes. The fabric that looked sharp on Day 1 needs to look decent on Day 300.

Testing labs measure durability. They don't guess. The Martindale abrasion test rubs fabric against standard rough material until it shows wear.

Athletic polyester beats cotton here. The man-made fibers resist friction damage better. They don't break down under repeated stress.

Tensile strength measures the maximum force before fabric tears. Seam strength tracks where garments fail—at the stitching. Cotton fibers weaken faster with washing and wear. Polyester keeps its structure longer. Period.

The Shape Battle

Cotton shirts stretch out. This isn't opinion. It's physics. ISO 5077 testing measures size change after washing and drying. Industry standards target <3% shrinkage for general apparel. Cotton often exceeds this. It shrinks in length. It stretches at the collar and cuffs. Those "durable-press" finishes on cotton try to fight this. They use chemical treatments to help fabric keep its initial shape, flat seams, and pressed-in creases after washing.

Polyester doesn't need these fixes. Man-made fibers are thermoplastic. Heat-set shapes stay put. Your polyester workout shirt fits the same in month six as it did brand new. Cotton? You're shopping for replacements.

Color Fade Reality

The Gray Scale grading system (ISO and AATCC standards) rates color staying power from 1 (severe) to 5 (no change). Premium brands demand grade 4+ minimum after set wash cycles.

Real-world testing on woven cotton fabrics with reactive dyes shows the challenge. After 20 home laundry cycles (wash plus tumble dry), well-processed reactive-dyed cotton keeps over 90% color strength for navy and black shades. The ΔE color change measures 0.7 to 1.7—within the acceptable ΔE ≤2.0 threshold for "no visible change."

But that's best-case cotton. With optimized dyes. Professional finishing. Most cotton athletic wear uses cheaper processes. Colors fade faster. Polyester holds dye better from the start. The man-made fiber bonds with disperse dyes at the molecular level. Washing doesn't strip color as much. Your black polyester training top stays black. Cotton turns charcoal gray after a season.

Pilling resistance matters too. That fuzzy ball formation on fabric surfaces gets graded 1 (severe) to 5 (none) after set rub cycles. Cotton pills more. The natural fibers tangle and mat at the surface. Polyester's smooth man-made structure fights this breakdown.

Bottom line: polyester athletic wear outlasts cotton by measurable margins. It holds shape better. Keeps color longer. Handles abrasion better. The durability gap isn't close.

5. Wrinkle Resistance & Care

Pull your cotton workout shirt from the dryer. It's a crumpled mess. Your polyester tank? Smooth and ready to wear. This difference comes from how the fibers are built.

Fabric labs measure wrinkle resistance on a 1-to-5 replica grading scale. Grade 5 means great recovery. Grade 1 means permanent creasing. Researchers hang washed fabrics for 24 hours. Then they grade the wrinkles against standard replicas.

Standard 100% cotton without treatment scores around 3.0 (mean score with standard deviation of 0.87). That's mediocre. Cotton wrinkles because its natural fibers lose their bonds during washing. These bonds reform in new positions as the fabric dries. Result: creases that won't quit.

The Chemical Fix for Cotton

Treated Cotton (PUREPRESS)

Untreated Cotton

PUREPRESS or durable-press (DP) treatments change cotton's makeup. These resin finishes create links between fiber molecules. The bonds lock fibers in place. Testing shows the impact with η² = 0.34 (large effect size) and p < .01 significance.

Here's what this means: treated cotton beats untreated fabric by +1.75 grades on average. That's the difference between "looks slept-in" and "looks fresh." But these treatments cost money. They add processing steps. Most budget athletic cotton skips them.

Polyester Needs No Help

Man-made polyester fibers are plastic-based. Heat-setting during production locks in shape at the fiber level. No chemical treatments needed. No special care required. Machine wash, tumble dry, pull it out smooth.

The care gap grows over time. Cotton athletic wear needs cold water, gentle cycles, air drying, maybe ironing. Polyester? Toss it in, regular wash, regular dry, done. You save time every laundry day. The iron stays in the closet.

Your workout schedule doesn't include ironing sessions. Choose fabric that works with your life, not against it.

6. Odor Management

Bacteria love sweat. They feast on it, grow in it, and turn your workout gear into a portable stink factory.

The smell isn't from your sweat itself. Fresh sweat is almost odorless—mostly water and salt. The stench comes from bacteria on your skin. They break down proteins and oils in that moisture. This produces smelly compounds. These smell terrible. The fabric you wear either fights this or helps it happen.

The Bacterial Battleground

Cotton absorbs moisture and holds it close to the fiber surface. This creates a warm, damp spot. Perfect for bacteria to grow. The natural fiber gives bacteria plenty of room to spread. Once bacteria settle in, they're hard to wash out. Each workout adds another layer of sweat. More food for the bacteria. More smell.

Polyester works differently. The synthetic fiber repels water. Sweat doesn't soak into the fiber core. Moisture spreads across the surface and dries faster. Less time wet means fewer bacteria stick around. The smooth surface gives bacteria less grip than cotton's rough surface.

Premium athletic polyester now includes antimicrobial treatments. Silver ions in the fiber kill bacteria on contact. Zinc finishes stop bacterial growth. These treatments aren't perfume covering up smell. They kill the bacteria creating odor.

The Washing Reality

Cotton workout gear needs washing right away. Let it sit in your gym bag overnight? The bacteria keep growing. The smell sets in. Even after washing, cotton fibers can still hold bacteria in their porous structure. You've experienced this: a shirt that smells fine when dry but stinks the moment you start sweating in it again.

Polyester releases bacteria better during washing. The synthetic fiber doesn't give bacteria deep hiding spots. A regular wash cycle clears most odor-causing buildup. The fabric resets better between workouts.

Want proof? Smell your cotton gym shirt after a week of workouts versus a polyester one. Both washed after each use. The difference is obvious. Science explains why polyester wins the odor war.

7. Use‑Case Fit: Type of Sport / Intensity

Different workouts need different clothes. Your heart rate shows what you need.

Sports scientists use five stages based on maximum heart rate (MHR):

Real training data proves this point. Provincial women's sitting volleyball teams spend 45.3% of their competitive week in low-intensity zones (Stages 1-2). Another 29.7% hits moderate intensity (Stage 3). The rest splits between high and extreme zones. Cotton handles the load for this training pattern. The sweat volume stays low. Natural fiber gives you more comfort than synthetics at these levels.

Position Determines Fabric Choice

Same sport, different positions, different needs. Here's how sitting volleyball breaks down:

Main Attackers (Pos 3)

Receivers (Pos 5)

Match your fabric to your actual heart rate data. Don't just go by your sport's name. The numbers show your real sweat load.