Full-Service Custom Sportswear Manufacturing Solutions

Decades of expertise delivering performance sportswear across 12 specialized categories. From cutting-edge fabric technology to precision craftsmanship, we transform your vision into reality.

Industry-Leading Experience

Since 1995, we've mastered sportswear craftsmanship serving 5000+ global brands with proven manufacturing reliability and innovation-driven production processes.

Startup-Friendly

MOQ

Begin with just 50 pieces – perfect for market testing without massive inventory commitment. Scale seamlessly to 10,000+ units with progressive volume discounts.

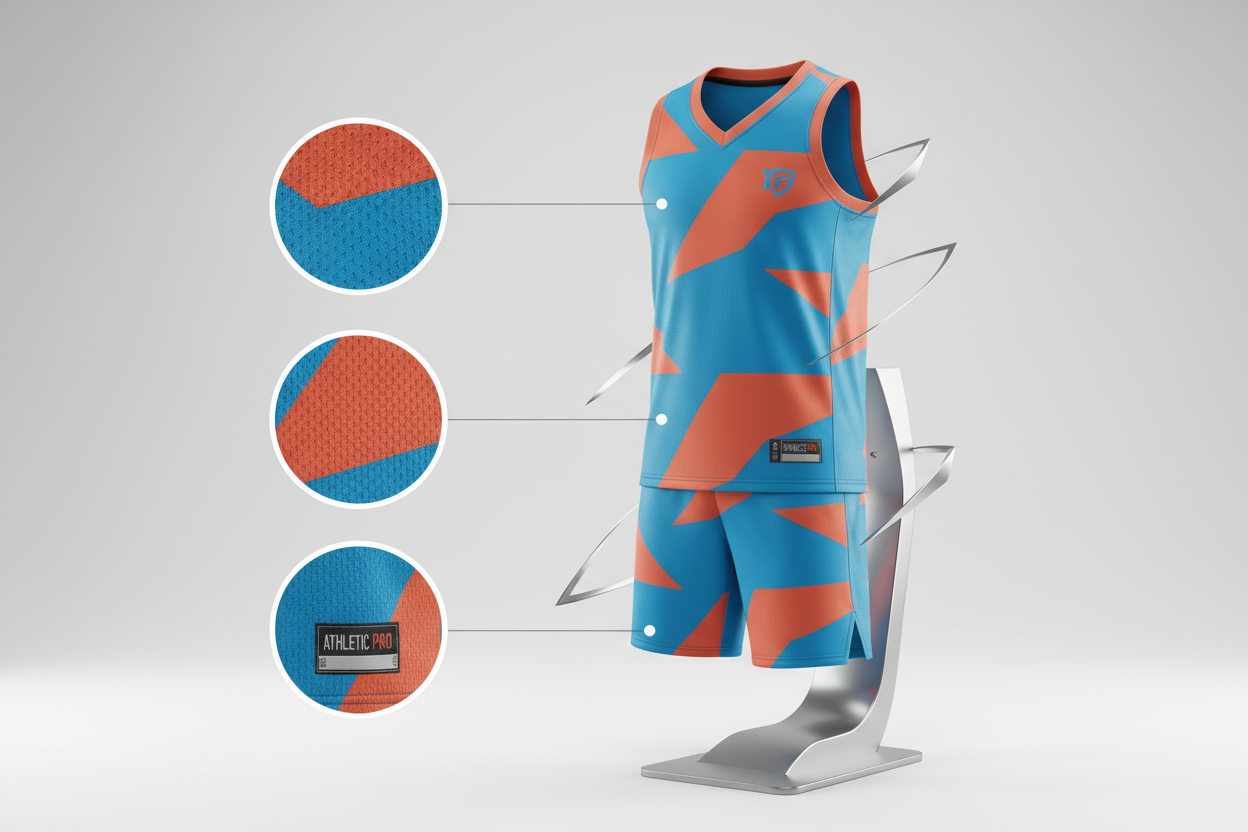

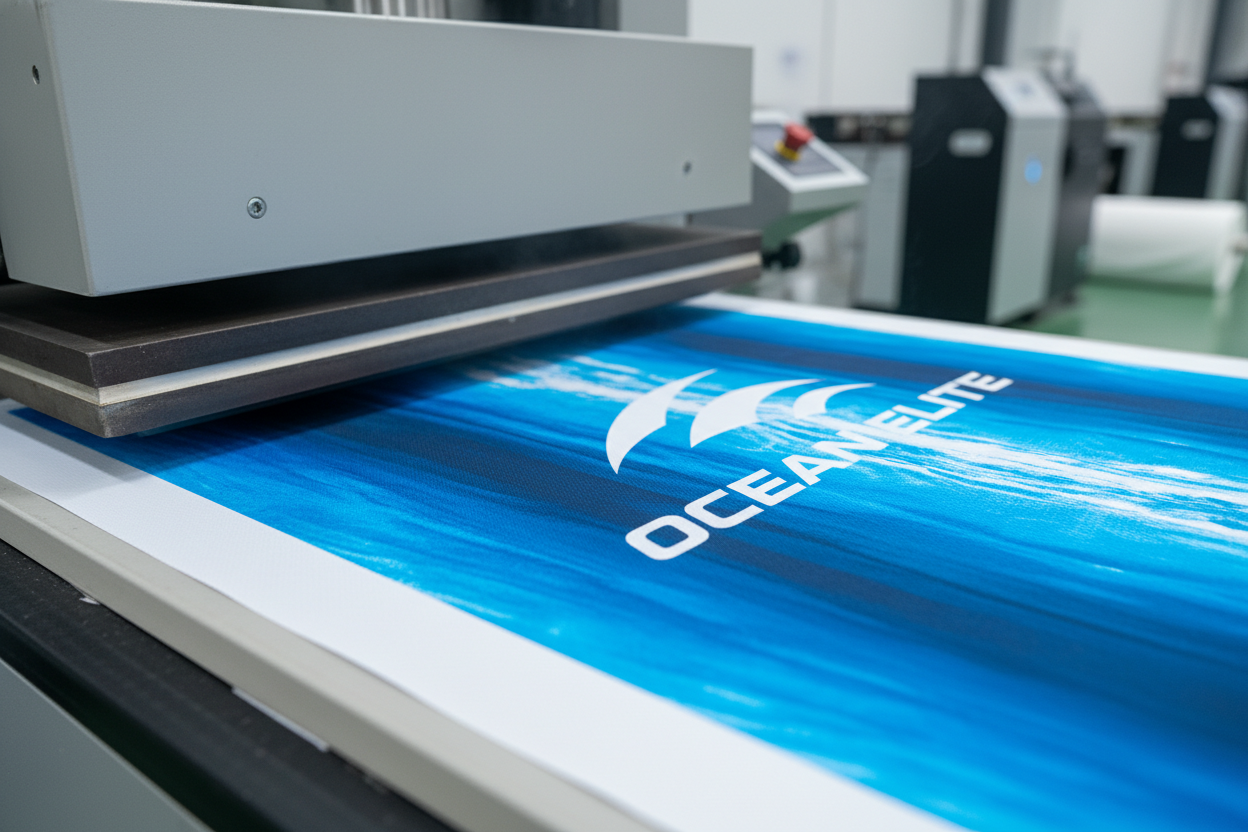

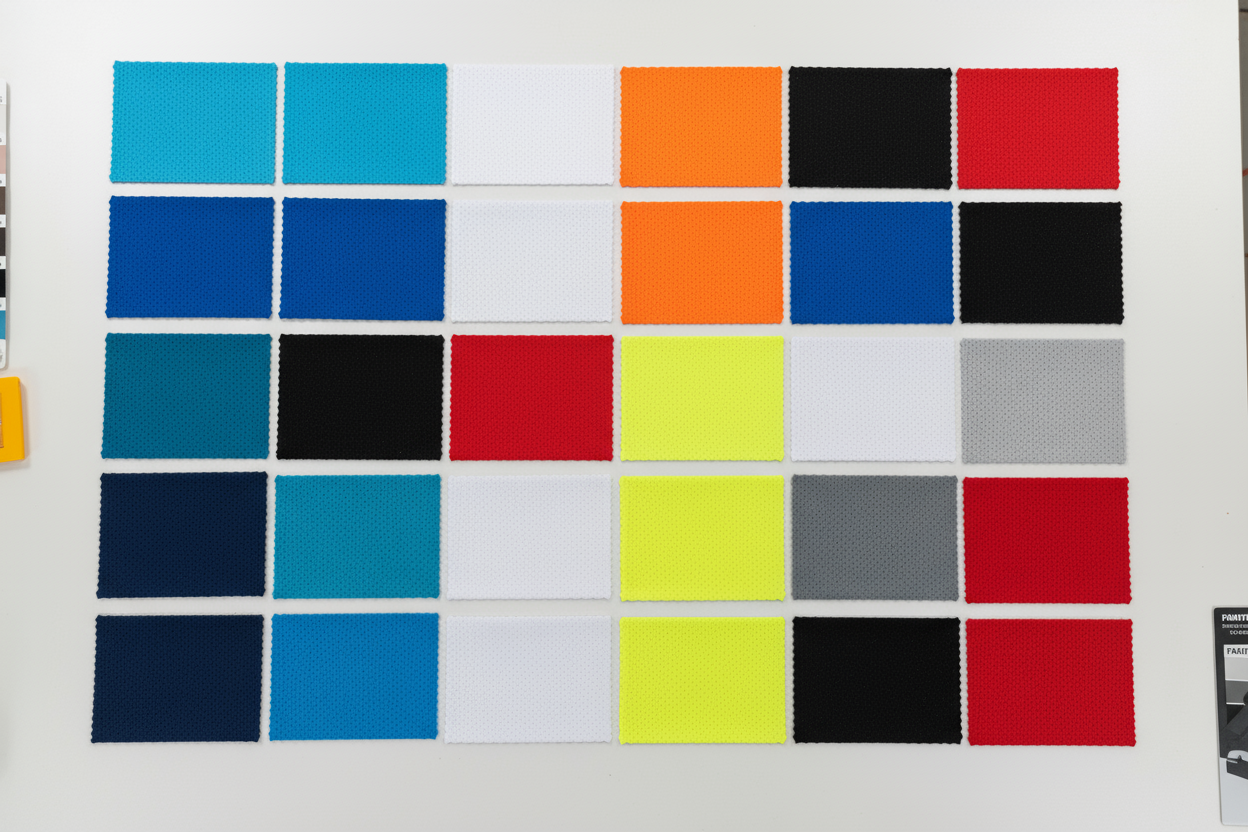

Full Customization

Complete control from fabric selection to finishing touches. Custom logo embroidery, sublimation printing, unique color matching, and branded packaging solutions.

Fast-Track Prototyping

Accelerate your product launch with 2-week sample turnaround. From tech pack submission to physical samples delivered for quality validation.

Explore Our Sportswear Product Categories

Expert OEM/ODM production across diverse sportswear segments with specialized fabric technology and sport-specific design expertise for each category.